Description

1. Product Description

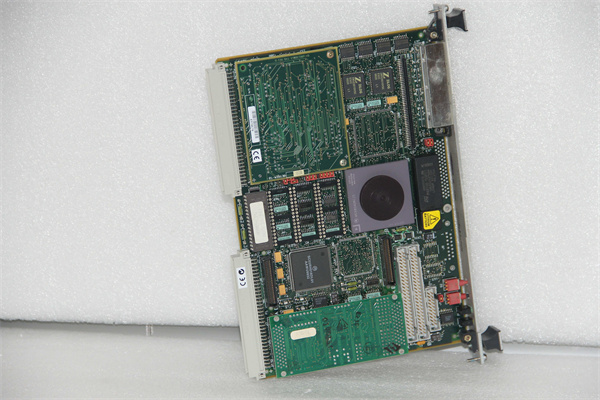

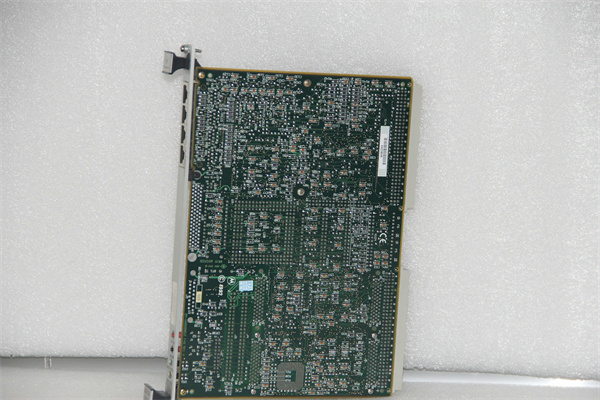

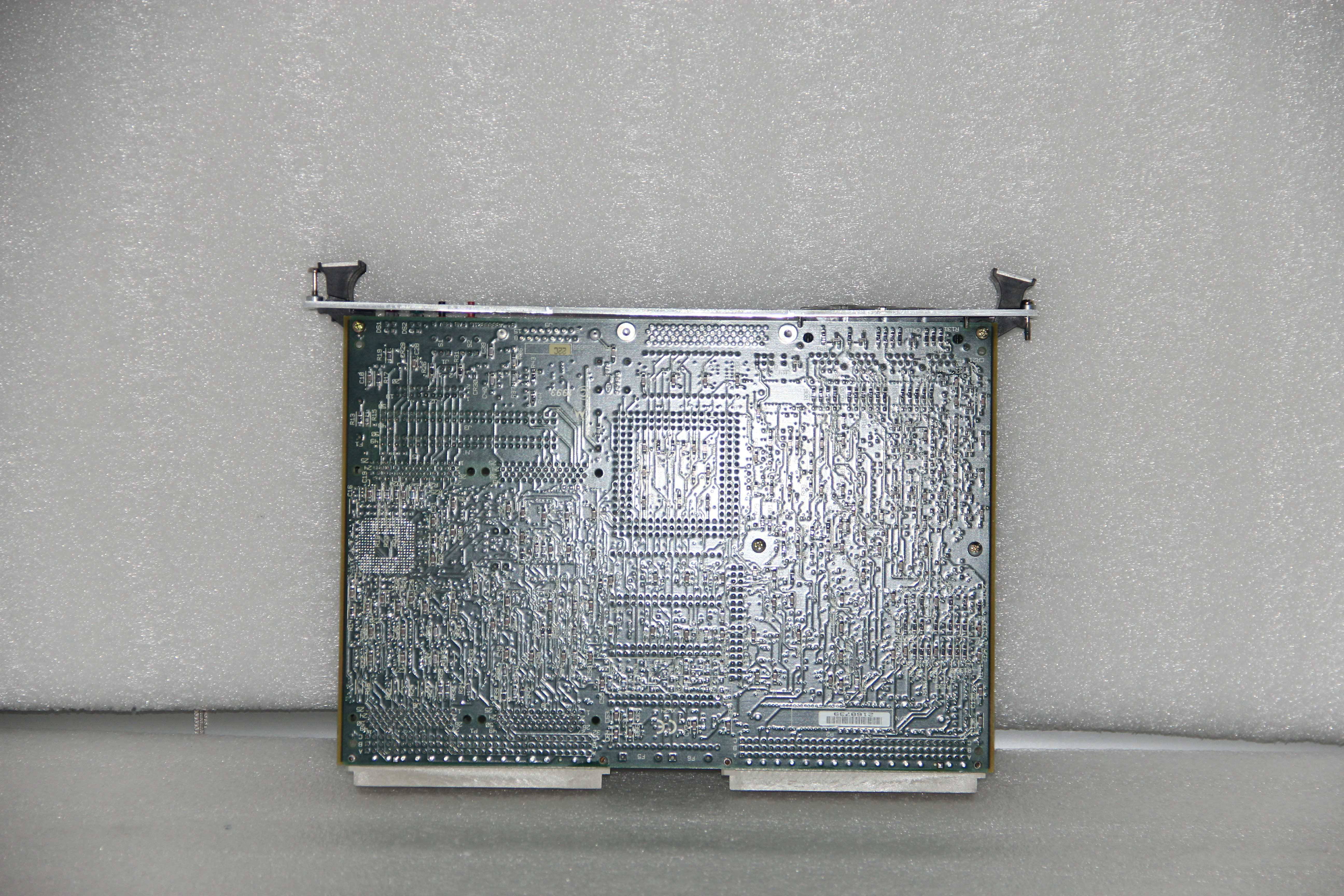

GE MVME162-220 is a high-performance industrial computer module designed for mission-critical automation and control systems. As part of GE Fanuc’s MVME series, the MVME162-220 combines robust processing power with versatile connectivity, making it ideal for industrial environments requiring reliability and scalability. The module features a PowerPC 750 processor, 1 GB of DDR2 memory, and supports VMEbus and PMC (PCI Mezzanine Card) expansion, enabling seamless integration into complex industrial networks. Its compact design and wide operating temperature range (-40°C to +85°C) ensure stable performance in harsh conditions. The MVME162-220 is widely used in manufacturing, energy, and transportation sectors for applications such as machine control, data acquisition, and real-time monitoring.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Processor | PowerPC 750 (up to 667 MHz) |

| Memory | 1 GB DDR2 SDRAM |

| Storage | CompactFlash slot (up to 4 GB) |

| Bus Interface | VMEbus (32-bit/33 MHz), PMC (PCI) |

| Voltage | +5V DC (±5%), +3.3V DC (±5%) |

| Operating Temperature | -40°C to +85°C (industrial grade) |

| Dimensions | 160 mm x 233.4 mm (VME 6U form factor) |

| MTBF | >50,000 hours (per MIL-HDBK-217F standard) |

MVME162-220

3. Advantages and Features

- High Reliability: Industrial-grade components and a rugged design ensure continuous operation in extreme temperatures and vibration-prone environments.

- Flexible Expansion: Supports PMC modules for custom I/O configurations (e.g., Ethernet, CANbus, or analog/digital I/O).

- Energy Efficiency: Low-power architecture (≤15W typical) reduces heat dissipation and operational costs.

- Real-Time Performance: Hard real-time capabilities with VxWorks, Linux, or Windows Embedded support.

- Long Lifecycle Support: Backed by GE Fanuc’s legacy of industrial computing, ensuring compatibility with older systems and long-term availability.

4. Application Areas and Use Cases

Industries: Manufacturing, oil and gas, power generation, transportation, and aerospace.

典型应用场景:

典型应用场景:

- Factory Automation: Controls robotic assembly lines with sub-millisecond response times.

- Energy Management: Monitors and optimizes power distribution in smart grids.

- Transportation Systems: Powers real-time traffic control systems in railways.

案例: A European automotive plant integrated the MVME162-220 into its welding robot network. The module’s real-time processing and PMC-based I/O expansion reduced downtime by 20% and improved weld quality through precise motion control.

5. Competitor Comparison

Compared to similar industrial computing modules, the MVME162-220 offers:

- Superior Compatibility: Native support for VMEbus and PMC, ensuring backward compatibility with legacy systems.

- Extended Temperature Range: Operates reliably in -40°C to +85°C, surpassing standard commercial-grade modules (0°C to +50°C).

- Higher Expansion Slots: Two PMC slots vs. one in many 竞品,enabling more flexible I/O configurations.

MVME162-220

6. Selection Recommendations

- Compatibility: Verify VMEbus and PMC module requirements (e.g., PCIe vs. PCI).

- Environment: Ensure the operating temperature (-40°C to +85°C) matches site conditions.

- Performance Needs: Balance processor speed (667 MHz) with memory (1 GB) for real-time vs. data-intensive tasks.

- Budget: Consider long-term costs (e.g., lifecycle support vs. upfront price of lower-spec alternatives).

7. Precautions

- Installation: Use ESD (electrostatic discharge) protection during handling.

- Cooling: Ensure adequate airflow in enclosed cabinets (max. 85°C ambient).

- Software: Validate OS compatibility (e.g., VxWorks 6.9, Linux 3.10).

- Maintenance: Schedule annual inspections for dust accumulation and connector integrity.