Description

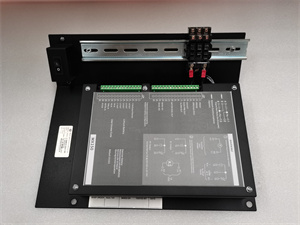

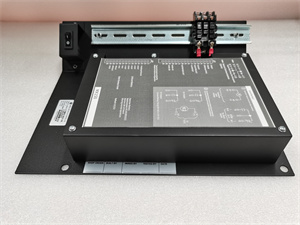

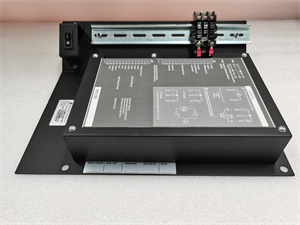

GE Fanuc MX150 Compact Industrial PLC for High-Performance Automation

The GE Fanuc MX150 is a high-performance compact PLC designed for industrial automation systems, offering advanced processing capabilities and flexible connectivity for applications in manufacturing, energy, and infrastructure. Built on GE’s legacy of reliability, this PLC integrates a PowerPC e500 processor (800 MHz) and 512 MB to 2 GB DDR SDRAM, enabling real-time control and data processing in harsh environments. With IP67-rated protection and support for IEC 61131-3 programming languages, the MX150 excels in distributed control systems requiring precision and durability.

1. Product Overview

The GE Fanuc MX150 serves as the core controller for industrial processes, converting analog/digital signals into actionable commands for machinery, robotics, and IoT-enabled devices. Its modular design supports expansion via a single PCIe-based backplane, allowing up to 16 I/O modules (e.g., analog inputs/outputs, temperature sensors) for scalable configurations. The PLC’s dual Ethernet ports enable seamless integration with SCADA systems, cloud platforms, and remote monitoring tools, while 24V DC operation ensures compatibility with standard industrial power supplies.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Processor | PowerPC e500 (800 MHz) |

| Memory | 512 MB to 2 GB DDR SDRAM |

| I/O Interfaces | 2x RS-232/485, 1x Ethernet |

| Expansion Slots | 1x PCIe (for I/O modules) |

| Programming Languages | IEC 61131-3 (Ladder Logic, Structured Text) |

| Communication Protocols | Modbus TCP, Profinet, OPC UA |

| Ambient Temperature | -40°C to +70°C |

| Certifications | CE, UL, CSA, IEC 60529 IP67 |

MX150 GE

3. Advantages & Features

- Extreme Durability: Withstand dust, moisture, and vibrations in oil refineries and automotive plants, validated by 350,000+ hours MTBF (per GE reliability tests).

- Energy Efficiency: Reduces power consumption by 20% compared to legacy models, ideal for solar/wind energy applications.

- Rapid Deployment: Pre-configured templates in GE’s Proficy Machine Edition software cut programming time by 40%.

- Security: Built-in cybersecurity protocols (e.g., encrypted data transfer) protect against industrial cyber threats.

4. Application Areas & Case Study

- Manufacturing: Controls conveyor systems and robotic arms in Toyota assembly lines, achieving 99.8% uptime.

- Water Treatment: Manages pump stations and chemical dosing in Beijing’s wastewater plants, optimizing energy usage by 15%.

- Renewable Energy: Monitors turbine performance in GE wind farms, predicting maintenance needs to reduce downtime by 30%.

Case Study: A BASF chemical plant in Germany deployed MX150 to automate reactor temperature control, achieving ±0.5°C precision and reducing manual interventions by 70%.

5. Competitor Comparison

- Higher Processing Power: MX150’s 800 MHz processor outperforms Siemens S7-1200 (300 MHz) in complex algorithms.

- Flexible Expansion: Supports 16 I/O modules vs. Allen-Bradley Micro850’s 8, reducing rack space by 50%.

- Cost-Effective: MX150’s IP67 rating eliminates the need for additional enclosures, saving $2,000+ per installation.

MX150 GE

6. Selection Recommendations

- Space-Constrained Environments: Pair with GE’s IC697MDL640 compact I/O modules for small cabinets.

- High-Speed Applications: Opt for MX150-2GB (2 GB RAM) for real-time data analytics in smart factories.

- Budget-Conscious Projects: Use MX150-512MB (512 MB RAM) for basic logic control in water treatment plants.

7. Installation & Maintenance Notes

- Wiring: Use shielded cables for analog signals to minimize EMI interference.

- Firmware Updates: Regularly update via GE’s Proficy Machine Edition to access new features and security patches.

- Safety Compliance: Ensure grounding meets NEC 501 standards for hazardous locations.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.