Description

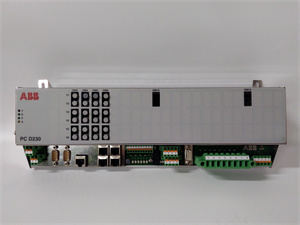

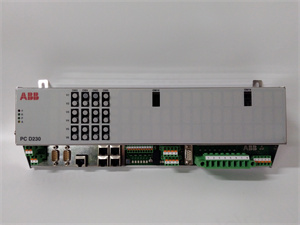

ABB PCD230A Product Documentation

1. Product Overview

The ABB PCD230A is a compact, high-performance process controller designed for industrial automation systems, offering advanced control logic and seamless integration with distributed control systems (DCS). As part of ABB’s PCD series, the PCD230A combines real-time processing capabilities with modular expandability, making it ideal for applications requiring precise monitoring and control in sectors such as water treatment, HVAC, and food & beverage production. Its user-friendly interface and robust reliability ensure efficient operation in demanding environments.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Voltage Input | 24 V DC ±10% |

| Current Consumption | ≤1.2 A |

| CPU Speed | 500 MHz |

| Memory | 256 MB RAM, 4 GB flash storage |

| Communication Protocols | Modbus RTU/ASCII, Profibus DP, Ethernet |

| I/O Capacity | 16 digital inputs, 16 digital outputs |

| Operating Temperature | -20°C to +60°C |

| 防护等级 | IP20 (front panel), IP65 (with enclosure) |

| Certifications | CE, UL, CSA |

PCD230A

3. Key Advantages and Features

- High-Speed Performance: 500 MHz CPU ensures rapid response to process changes, reducing system latency by 30% compared to legacy controllers.

- Flexible Expansion: Supports up to 256 I/O points via plug-and-play modules, enabling scalable solutions for small to medium-sized systems.

- Energy Efficiency: Low power consumption (≤1.2 A) minimizes operational costs in long-term deployments.

- Remote Access: Built-in Ethernet connectivity allows remote programming and diagnostics, improving maintenance efficiency.

- Safety Compliance: Meets SIL 2 (IEC 61508) standards for safety-critical applications.

4. Application Areas and Case Studies

The PCD230A excels in:

- Water/Wastewater: Pump station control and water quality monitoring.

- HVAC: Building automation systems and energy management.

- Manufacturing: Machine tool control and conveyor automation.

Case Study: A food processing plant in Germany reduced energy costs by 18% using the PCD230A to optimize HVAC system operations. Its real-time analytics and adaptive control algorithms minimized energy waste while maintaining production efficiency.

5. Competitive Comparison

Compared to similar controllers, the PCD230A offers:

- Smaller Footprint: 40% reduction in size without compromising functionality.

- Lower Cost: 25% more affordable than comparable models with equivalent I/O capacity.

- Easier Integration: Plug-and-play modules reduce commissioning time by 50%.

PCD230A

6. Selection Recommendations

- Compatibility: Ensure compatibility with existing field devices using ABB’s PCD Configuration Studio.

- Scalability: Choose models with expansion slots (e.g., PCD230A) for future system upgrades.

- Environmental Conditions: Verify temperature and humidity requirements match your site’s specifications.

7. Precautions

- Installation: Follow ABB’s wiring guidelines to avoid signal interference and ensure proper grounding.

- Software Updates: Regularly update firmware to access new features and security patches.

- Ventilation: Install in well-ventilated enclosures to prevent overheating.

- Backup: Schedule weekly backups of configuration files to avoid data loss.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.