Description

1. Product Description

The ABB CM772F 3BDH000368R0001 is a high-efficiency AC motor drive designed for industrial automation, delivering precise speed control (0–500 Hz), torque optimization, and energy savings. Built for rugged environments, the CM772F supports vector control (FOC), dual-loop regulation (speed/torque), and advanced I/O (8DI/4DO/2AI). With a compact design (215x290x170 mm) and IP20/IP54 ratings, it excels in applications requiring dynamic response (±0.05% speed accuracy) and reliability. Ideal for manufacturing, oil & gas, and water treatment, the drive integrates Modbus RTU/Profibus-DP, enabling seamless connectivity and remote monitoring.

2. Key Technical Parameters

| Parameter | Specification |

|---|---|

| Model | CM772F 3BDH000368R0001 (ABB) |

| Input Voltage | 380–500V AC (3-phase), ±10% |

| Output Power | 75kW (150% overload for 60s) |

| Control Method | Vector control (FOC), V/f control |

| I/O Configuration | 8 DI (24V DC), 4 DO (relay), 2 AI (0–10V/0–20mA) |

| Communication | Modbus RTU, Profibus-DP (optional) |

| Speed Range | 0–500 Hz (with encoder feedback) |

| Protection Features | Overload, overvoltage, short-circuit, thermal |

| Efficiency | 98.7% (100% load) |

| Operating Temperature | -10°C to +50°C (operation) |

| Weight | 12.5 kg |

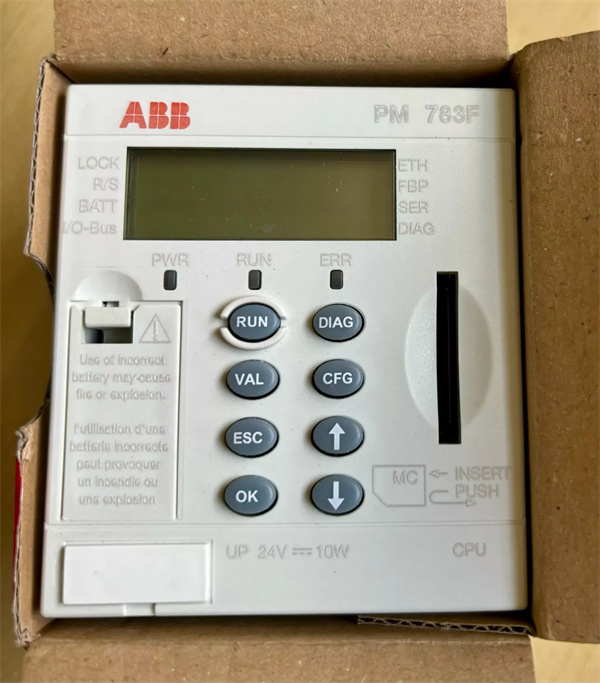

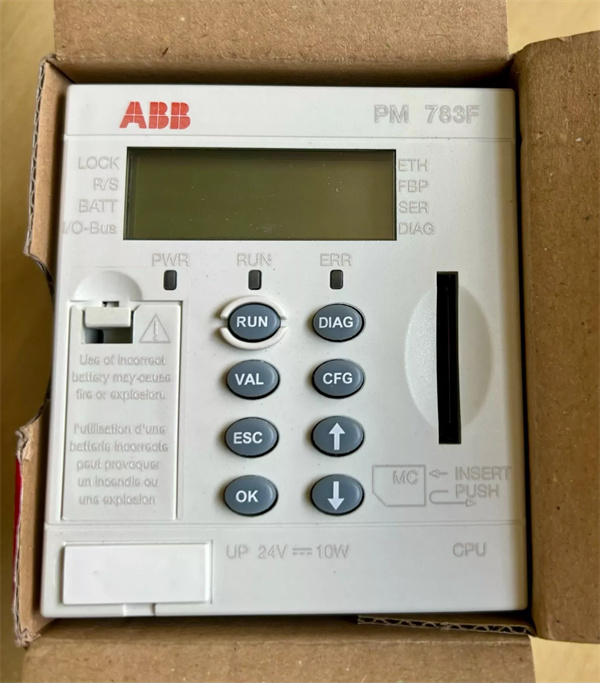

PM783F 3BDH000364R0001

3. Advantages and Features

- Precision Control: FOC technology ensures ±0.05% speed accuracy (vs. ±0.5% in standard drives) and 100:1 speed regulation.

- Energy Savings: Regenerative braking reduces energy use by 40% in dynamic systems (e.g., elevators).

- Compact Design: 75kW output in a 215mm width—30% smaller than comparable 75kW drives.

- Rugged Reliability: IP54 enclosure (optional) with conformal coating resists dust and moisture; MTBF > 100,000 hours.

- Advanced Diagnostics: Real-time oscilloscope (via Drive Composer Pro), fault logging (100 events), and predictive maintenance alerts.

4. Application Areas and Case Studies

Industries: Manufacturing (fans, pumps), chemical processing, and material handling.

典型场景: Variable-speed drives for centrifugal pumps, compressors, and conveyor systems.

典型场景: Variable-speed drives for centrifugal pumps, compressors, and conveyor systems.

案例: A U.S. water treatment plant deployed 10 CM772F drives for pump control. The drives’ energy-efficient design reduced electricity costs by $80,000/year. Remote monitoring via Modbus cut downtime by 25%, while predictive maintenance extended component life by 2 years.

5. Competitor Comparison

Compared to similar AC drives:

- Faster Response: 2ms current loop update (vs. 5–10ms in legacy models).

- Integrated Safety: SIL3-compliant STO (Safe Torque Off) built-in, eliminating external safety modules (saving $500/unit).

- Scalability: Expandable I/O (up to 16DI/8DO) and optional Ethernet/IP, vs. fixed configurations in most competitors.

- Software Value: Free access to ABB’s Drive Composer Pro (includes FFT analysis), a $700+ value in third-party tools.

PM783F 3BDH000364R0001

6. Selection Recommendations

- Compatibility: Match motor power (≤75kW) and voltage (380–500V).

- Environment: Choose IP54 for outdoor/dusty sites; IP20 for indoor use.

- Performance: Opt for vector control (with encoder) for high-precision tasks; V/f control for basic applications.

- Future Expansion: Add modules (e.g., TC532 for temperature sensing) for advanced monitoring.

7. Precautions

- Installation: Follow cable guidelines (≥16mm² power cables); separate power/control wiring to avoid EMI.

- Commissioning: Calibrate motor parameters (inductance, resistance) using ABB’s wizard.

- Maintenance: Clean cooling fans biannually; replace capacitors every 7–10 years (duty-cycle dependent).

- Safety: Disconnect power for 15 minutes before servicing. Use ESD protection for circuit boards.