Description

Product Description: ABB PP825 3BSE042240R1

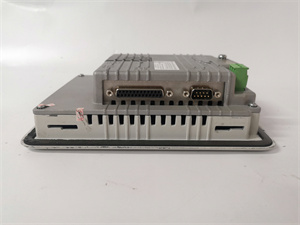

The ABB PP825 3BSE042240R1 is a high-performance PLC module designed for industrial automation and process control applications. As part of ABB’s advanced automation portfolio, the PP825 3BSE042240R1 combines robust hardware with intelligent software to deliver precise control, scalability, and reliability in demanding environments. Ideal for industries such as manufacturing, energy, and water treatment, this module supports real-time data processing, seamless integration with existing systems, and flexible configuration for diverse operational needs. The PP825 3BSE042240R1 is engineered to optimize performance, reduce downtime, and enhance overall system efficiency.

Product Parameters

| Parameter | Specification |

|---|---|

| Brand | ABB |

| Model | PP825 3BSE042240R1 |

| Voltage | 24 V DC (±10%) |

| Current Consumption | ≤500 mA |

| Processor | 32-bit ARM Cortex™-M4 (400 MHz) |

| Memory | 512 MB RAM, 4 GB flash storage |

| Interfaces | Ethernet/IP, Modbus RTU (RS485), CANopen |

| I/O Capacity | Supports up to 1,024 digital/analog I/O |

| Compatibility | ABB AC500 PLC system, third-party devices |

| Operating Temperature | -20°C to +60°C (with extended range options) |

PP825 3BSE042240R1

Advantages and Features

- High Reliability: Built with industrial-grade components, the PP825 3BSE042240R1 ensures continuous operation in harsh conditions (e.g., vibration, temperature fluctuations). It meets IEC 61131-2 and EN 60079-15 standards for safety and durability.

- Modular Design: Easy to install and expand, with hot-swap capabilities for quick maintenance. Its compact size (120 mm × 100 mm × 80 mm) saves space in control cabinets.

- Energy Efficiency: Low power consumption (≤500 mA) reduces operational costs while maintaining high performance.

- Advanced Communication: Supports multiple protocols (Ethernet/IP, Modbus, CANopen) for seamless integration with IoT platforms and cloud-based systems.

- Real-Time Processing: 400 MHz processor enables fast data handling (cycle time: ≤1 ms for typical applications).

Application Areas and Case Studies

Industries:

- Manufacturing (assembly lines, robotics)

- Energy (power plants, renewable energy systems)

- Water/Wastewater Treatment

- Oil and Gas (process control)

Case Study:

A major automotive manufacturer upgraded its assembly line with the PP825 3BSE042240R1. The module’s real-time control and Ethernet/IP connectivity optimized robot coordination, reducing cycle time by 15% and improving uptime by 20%. The modular design also simplified system expansion for new production lines.

Competitor Comparison

Compared to similar PLC modules on the market, the PP825 3BSE042240R1 offers:

- Superior Compatibility: Native support for ABB’s AC500 system and open protocols, minimizing integration complexity.

- Cost-Effectiveness: Lower total cost of ownership (TCO) due to energy efficiency and long service life (MTBF > 100,000 hours).

- Flexibility: Scalable I/O capacity (up to 1,024 points) versus competitors’ fixed configurations.

PP825 3BSE042240R1

Selection Recommendations

- Compatibility: Ensure alignment with your existing PLC system (e.g., ABB AC500) and protocol requirements.

- Environment: Choose extended temperature models (-40°C to +70°C) for extreme climates.

- Scalability: Plan for future expansions by selecting modules with redundant I/O slots.

- Budget: Balance performance needs with cost—the PP825 3BSE042240R1 offers mid-range pricing with high ROI.

Precautions

- Installation:

- Follow ESD (electrostatic discharge) protection guidelines.

- Ensure proper ventilation and temperature control in the cabinet.

- Maintenance:

- Regularly check firmware updates (via ABB’s AC500 Software).

- Replace batteries (for backup memory) every 5–7 years.

- Safety:

- Disconnect power before modifying wiring or components.

- Adhere to local safety standards (e.g., NEC, IEC).