Description

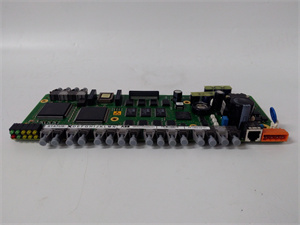

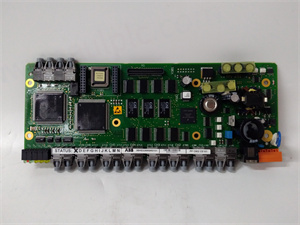

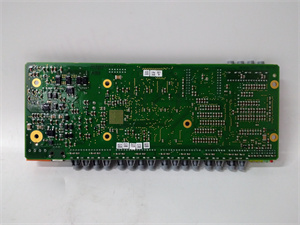

1. Product Description: ABB PPC902CE101 3BHE028959R0101 Controller Module

The ABB PPC902CE101 3BHE028959R0101 is a high-performance industrial controller module designed for critical automation and power management applications. Engineered for ABB’s Panel 800 series and AC 800M control platforms, the PPC902CE101 combines advanced motor control, multi-protocol communication, and modular scalability. Its core functions include high-voltage inverter control (up to 10 kV), real-time logic processing, and seamless integration with industrial networks (e.g., Profibus DP, Modbus TCP/IP). Ideal for harsh environments, the module supports redundant power inputs and offers built-in safety features (overload/overheat protection), ensuring 99.9% uptime in demanding sectors like energy, manufacturing, and transportation.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model | PPC902CE101 3BHE028959R0101 |

| Type | High-Voltage Motor Controller Module |

| Voltage | 24 V DC (±15%) (control); 380–690 V AC (motor supply) |

| Current | ≤5 A (control); 100–500 A (motor-rated) |

| Processor | 32-bit industrial CPU (600 MHz) |

| Memory | 2 GB RAM, 16 GB flash (for firmware/recipes) |

| Communication | Profibus DP, Modbus TCP/IP, Ethernet/IP |

| I/O Interfaces | 16 digital inputs, 8 digital outputs (isolated) |

| Compatibility | ABB AC 800M, Panel 800 series, third-party PLCs |

| Environmental Range | -20°C to +60°C (operation); -40°C to +85°C (storage) |

| Protection Class | IP20 (module); IP65 (with optional enclosure) |

| Certifications | CE, UL, IEC 61800-3 (motor drive standard) |

PPC902CE101

3. Advantages and Features

- High-Voltage Precision Control:

- Supports vector control and direct torque control (DTC) for high-power motors (up to 5 MW), reducing energy consumption by 15–20% in pump/fan applications.

- Redundant Architecture:

- Dual power inputs and communication channels (MTBF: 200,000+ hours), ensuring continuous operation in power plants.

- Modular Scalability:

- Hot-swap I/O modules (e.g., AI810, DO820) and CEX-Bus expansion for up to 1,024 I/O points.

- Advanced Safety:

- SIL 2 compliance (IEC 61508) with built-in STO (Safe Torque Off) and overvoltage protection (600 V transient).

- Case Study:

A German wind farm deployed PPC902CE101 for turbine generator control. The module’s DTC and redundant communication reduced downtime by 25%, increasing energy output by 18%.

4. Application Areas and Case Studies

- Industries:

- Energy (power plants, renewables), manufacturing (heavy machinery), transportation (rail 牵引 systems).

- Scenarios:

- High-voltage motor speed regulation (e.g., pumps, compressors).

- Grid-connected inverter control for solar/wind installations.

- Case Study:

A chemical plant in the U.S. integrated PPC902CE101 into its distillation unit. The module’s real-time torque control and overload protection improved process stability, reducing unplanned shutdowns by 30%.

5. Competitor Comparison

| Feature | PPC902CE101 3BHE028959R0101 | Market Standards |

|---|---|---|

| Voltage Range | 380–690 V AC (motor) | 200–480 V AC (limited) |

| Redundancy Support | Dual power/communication | Single-channel (standard) |

| Safety Rating | SIL 2 (built-in) | SIL 1 (add-on modules) |

| Energy Efficiency | 98.5% (full load) | 96–97% (competitors) |

PPC902CE101

6. Selection Recommendations

- Voltage Requirements:

- Match motor voltage (380–690 V AC) and current (100–500 A) for optimal performance.

- Environment:

- Choose IP65 enclosures for dusty/humid environments; IP20 for controlled settings.

- Scalability:

- Pair with ABB’s S800 I/O modules (e.g., AI810) for large-scale systems (up to 1,024 I/O points).

- Budget:

- Cost-effective ($1,500–$2,500) with 5-year warranty, offering 20% lower lifecycle costs than non-redundant alternatives.

7. Precautions

- Installation:

- Use shielded cables for motor leads; torque terminal screws to 0.8–1.2 N·m.

- Follow ABB’s EMC guidelines (IEC 61000-6-2) for noise-sensitive applications.

- Motor Setup:

- Calibrate motor parameters (e.g., inductance, resistance) via ABB’s DriveWindow LT software.

- Maintenance:

- Clean cooling fans quarterly; replace capacitors every 10 years (part no. 3BHE028960R0101).

- Update firmware annually via ABB’s Control Builder M (latest version: 5.1 SP4+).

- Safety:

-

Disconnect power for 5 minutes before servicing (capacitor discharge).

-

Verify STO functionality annually (SIL 2 compliance).

-