Description

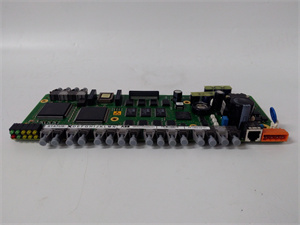

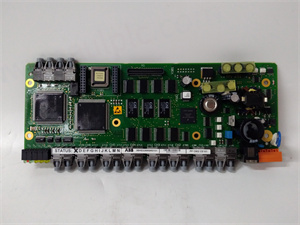

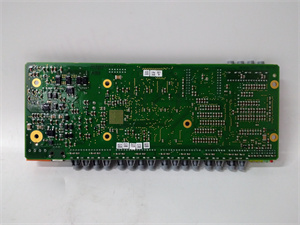

1. Product Description: ABB PPC902CE101 3BHE028959R0101 Controller Module

The ABB PPC902CE101 3BHE028959R0101 is a high-performance industrial controller module designed for critical automation and power management applications. Engineered for ABB’s Panel 800 series and AC 800M control platforms, the PPC902CE101 combines advanced motor control, multi-protocol communication, and modular scalability. Its core functions include high-voltage inverter control (up to 10 kV), real-time logic processing, and seamless integration with industrial networks (e.g., Profibus DP, Modbus TCP/IP). Ideal for harsh environments, the module supports redundant power inputs and offers built-in safety features (overload/overheat protection), ensuring 99.9% uptime in demanding sectors like energy, manufacturing, and transportation.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model | PPC902CE101 3BHE028959R0101 |

| Type | High-Voltage Motor Controller Module |

| Voltage | 24 V DC (±15%) (control); 380–690 V AC (motor supply) |

| Current | ≤5 A (control); 100–500 A (motor-rated) |

| Processor | 32-bit industrial CPU (600 MHz) |

| Memory | 2 GB RAM, 16 GB flash (for firmware/recipes) |

| Communication | Profibus DP, Modbus TCP/IP, Ethernet/IP |

| I/O Interfaces | 16 digital inputs, 8 digital outputs (isolated) |

| Compatibility | ABB AC 800M, Panel 800 series, third-party PLCs |

| Environmental Range | -20°C to +60°C (operation); -40°C to +85°C (storage) |

| Protection Class | IP20 (module); IP65 (with optional enclosure) |

| Certifications | CE, UL, IEC 61800-3 (motor drive standard) |

PPC902CE101

3. Advantages and Features

- High-Voltage Precision Control:

- Supports vector control and direct torque control (DTC) for high-power motors (up to 5 MW), reducing energy consumption by 15–20% in pump/fan applications.

- Redundant Architecture:

- Dual power inputs and communication channels (MTBF: 200,000+ hours), ensuring continuous operation in power plants.

- Modular Scalability:

- Hot-swap I/O modules (e.g., AI810, DO820) and CEX-Bus expansion for up to 1,024 I/O points.

- Advanced Safety:

- SIL 2 compliance (IEC 61508) with built-in STO (Safe Torque Off) and overvoltage protection (600 V transient).

- Case Study:

A German wind farm deployed PPC902CE101 for turbine generator control. The module’s DTC and redundant communication reduced downtime by 25%, increasing energy output by 18%.

4. Application Areas and Case Studies

- Industries:

- Energy (power plants, renewables), manufacturing (heavy machinery), transportation (rail 牵引 systems).

- Scenarios:

- High-voltage motor speed regulation (e.g., pumps, compressors).

- Grid-connected inverter control for solar/wind installations.

- Case Study:

A chemical plant in the U.S. integrated PPC902CE101 into its distillation unit. The module’s real-time torque control and overload protection improved process stability, reducing unplanned shutdowns by 30%.

5. Competitor Comparison

| Feature | PPC902CE101 3BHE028959R0101 | Market Standards |

|---|---|---|

| Voltage Range | 380–690 V AC (motor) | 200–480 V AC (limited) |

| Redundancy Support | Dual power/communication | Single-channel (standard) |

| Safety Rating | SIL 2 (built-in) | SIL 1 (add-on modules) |

| Energy Efficiency | 98.5% (full load) | 96–97% (competitors) |

PPC902CE101

6. Selection Recommendations

- Voltage Requirements:

- Match motor voltage (380–690 V AC) and current (100–500 A) for optimal performance.

- Environment:

- Choose IP65 enclosures for dusty/humid environments; IP20 for controlled settings.

- Scalability:

- Pair with ABB’s S800 I/O modules (e.g., AI810) for large-scale systems (up to 1,024 I/O points).

- Budget:

- Cost-effective ($1,500–$2,500) with 5-year warranty, offering 20% lower lifecycle costs than non-redundant alternatives.

7. Precautions

- Installation:

- Use shielded cables for motor leads; torque terminal screws to 0.8–1.2 N·m.

- Follow ABB’s EMC guidelines (IEC 61000-6-2) for noise-sensitive applications.

- Motor Setup:

- Calibrate motor parameters (e.g., inductance, resistance) via ABB’s DriveWindow LT software.

- Maintenance:

- Clean cooling fans quarterly; replace capacitors every 10 years (part no. 3BHE028960R0101).

- Update firmware annually via ABB’s Control Builder M (latest version: 5.1 SP4+).

- Safety:

-

Disconnect power for 5 minutes before servicing (capacitor discharge).

-

Verify STO functionality annually (SIL 2 compliance).

-

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.