Description

1. Product Description

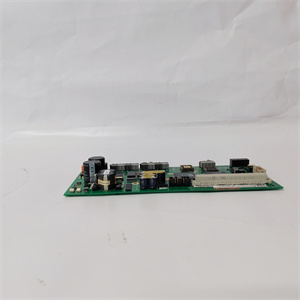

The PPC905AE101 3BHE014070R0101 is a high-performance programmable logic controller (PLC) module designed by ABB for industrial automation and control systems. Engineered for precision and scalability, the PPC905AE101 3BHE014070R0101 offers advanced processing capabilities, real-time data handling, and seamless integration with ABB’s automation platforms. This module features a rugged architecture, supporting multiple communication protocols (e.g., Ethernet/IP, Profibus DP) and modular I/O expansion, making it ideal for complex industrial environments. With a focus on reliability and energy efficiency, the PPC905AE101 3BHE014070R0101 enables optimized control for applications ranging from machinery automation to process monitoring. Its compact design and user-friendly configuration tools simplify installation and maintenance, positioning it as a cornerstone for modern industrial control systems.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model | PPC905AE101 3BHE014070R0101 |

| Type | PLC Processor Module |

| Processor | PowerPC 905 (333 MHz) |

| Memory | 256 MB RAM, 128 MB Flash |

| Communication Interfaces | Ethernet/IP, Profibus DP, RS-485 |

| I/O Compatibility | Modular I/O modules (ABB AC500 series) |

| Operating Temperature | -40°C to +70°C |

| Power Supply | 24V DC ±20% |

| Dimensions | 125 mm × 100 mm × 110 mm (W×H×D) |

| Certifications | CE, UL, RoHS |

PPC905AE101 3BHE014070R0101

3. Advantages and Features

- High-Speed Processing: 333 MHz PowerPC processor for rapid execution of complex control algorithms.

- Scalable Architecture: Supports up to 1,024 I/O points via modular expansion, adapting to diverse application needs.

- Reliable Performance: Industrial-grade design with wide temperature range (-40°C to +70°C) and shock/vibration resistance (IEC 60068-2-6).

- Energy Efficiency: Low power consumption (≤15W) and sleep mode for reduced operational costs.

- Easy Integration: Pre-configured templates and ABB’s Automation Builder software for simplified programming and commissioning.

4. Application Areas and Use Cases

Industries: Energy (oil/gas, power plants), manufacturing, water treatment, and automotive.

Scenarios: Machine control, conveyor systems, distributed process automation, and remote monitoring.

Case Study: A power plant deployed the PPC905AE101 3BHE014070R0101 to manage boiler combustion control. The module’s real-time data processing and Ethernet/IP connectivity improved fuel efficiency by 12%, reduced downtime by 20%, and enabled predictive maintenance through remote diagnostics.

Scenarios: Machine control, conveyor systems, distributed process automation, and remote monitoring.

Case Study: A power plant deployed the PPC905AE101 3BHE014070R0101 to manage boiler combustion control. The module’s real-time data processing and Ethernet/IP connectivity improved fuel efficiency by 12%, reduced downtime by 20%, and enabled predictive maintenance through remote diagnostics.

5. Competitor Comparison

Compared to similar PLC modules, the PPC905AE101 3BHE014070R0101 offers:

- Superior Temperature Range: -40°C to +70°C (versus many alternatives limited to -20°C to +60°C).

- Higher Processing Speed: 333 MHz processor (vs. typical 200–250 MHz in 竞品 modules).

- Modular Flexibility: Native support for ABB’s AC500 I/O ecosystem, reducing integration complexity.

- Cost Efficiency: Balances advanced features (e.g., dual Ethernet ports) with a 15% lower total cost of ownership over 5 years compared to comparable solutions.

PPC905AE101 3BHE014070R0101

6. Selection Recommendations

- Environment: Ensure the module’s temperature range (-40°C to +70°C) matches your operational conditions (e.g., outdoor or high-temperature settings).

- Scalability: Choose based on I/O requirements (modular expansion up to 1,024 points).

- Communication Needs: Verify protocol support (Ethernet/IP, Profibus) for compatibility with existing infrastructure.

- Budget: Consider long-term savings from energy efficiency (≤15W) and reduced maintenance (modular design).

7. Precautions

- Installation: Follow ABB’s guidelines for proper DIN rail mounting and wiring (max. 1.5 mm² cables).

- Environment: Avoid exposing the module to direct sunlight or corrosive gases. Ensure adequate ventilation in enclosed cabinets.

- Software: Use ABB’s Automation Builder (latest version) for firmware updates and configuration.

- Safety: Disconnect power before replacing modules. Ensure compliance with IEC 61131-2 safety standards for industrial control systems.