Description

ABB PPD113-B03-23-111615 Product Specification

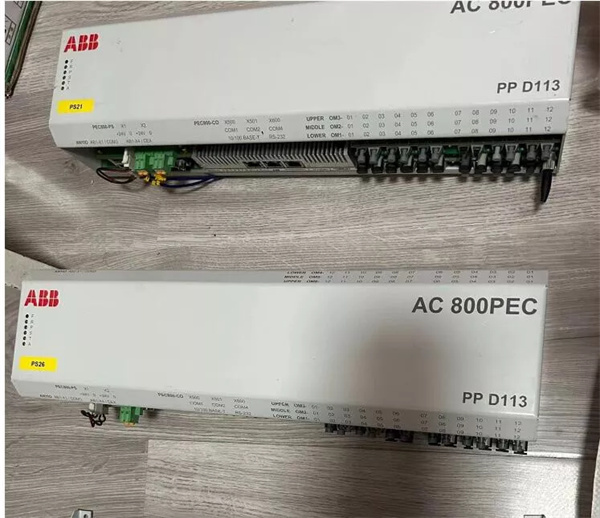

1. Product Description

The ABB PPD113-B03-23-111615 is a high-performance 双核 processor unit designed for industrial automation systems, particularly the AC 800PEC controller platform. It integrates high-speed control tasks (up to 100 μs cycle time) with low-speed process control, combining the robustness of a programmable logic controller (PLC) with advanced computational capabilities. The module features a rugged, modular architecture with built-in redundant Ethernet ports, supporting standard communication protocols (e.g., PROFIBUS DP) for seamless integration into industrial networks. Its compact design and IP20 protection make it suitable for diverse industrial environments, while compatibility with ABB Ability™ System 800xA ensures scalability and interoperability. The PPD113-B03-23-111615 prioritizes reliability with a fail-safe file system, eliminating data loss during power interruptions, and supports FPGA-based protocol handling to reduce processor load.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Voltage | 24V DC |

| Cycle Time | Up to 100 μs |

| Communication Interfaces | Ethernet (10/100 Mbps, redundant), PROFIBUS DP |

| Processor | Dual-core industrial-grade CPU |

| Memory | Embedded storage with fail-safe file system |

| Environmental Range | Temperature: 0–60°C; Humidity: 5–95% (non-condensing) |

| Protection Class | IP20 |

| Mounting | Din-rail or panel-mounted |

3. Advantages and Features

- High-Speed Performance: Short cycle times (100 μs) and dual-core processing enable real-time control for demanding applications.

- Modular Scalability: Supports step-by-step system expansion with compatible I/O modules and communication protocols.

- Reliability: Industrial-grade hardware (no moving parts), EMC certification, and fail-safe storage ensure stable operation in harsh environments.

- Energy Efficiency: Low power consumption and optimized FPGA-based protocol handling reduce operational costs.

- Integration Flexibility: Full compatibility with ABB’s 800xA system and standard tools (IEC 61131-3, MATLAB®/Simulink®) for model-based design.

PPD113-B03-23-111615

4. Application Areas and Use Cases

- Industries: Manufacturing, energy, oil and gas, and process automation.

- Scenarios: Machine control, conveyor systems, power generation, and distributed control systems (DCS).

- Case Study: A steel mill implemented the PPD113-B03-23-111615 in its rolling line control system. The module’s real-time processing and redundant communication minimized downtime, improving production efficiency by 15% while reducing maintenance costs through predictive diagnostics.

5. Competitive Differentiation

Compared to similar PLC modules, the PPD113-B03-23-111615 stands out with:

- Dual-Core Architecture: Combines high-speed logic with process control in a single unit, reducing system complexity.

- FPGA Integration: Offloads protocol processing, enhancing CPU efficiency.

- Seamless 800xA Integration: Pre-configured compatibility with ABB’s advanced DCS, eliminating customization efforts.

- Longevity: Industrial-grade components and modular design support upgrades over decades, avoiding premature obsolescence.

6. Selection Recommendations

- Compatibility: Ensure alignment with existing ABB systems (e.g., AC 800PEC, 800xA) and network protocols.

- Environment: Evaluate temperature/humidity ranges and choose IP20 or enclosed options for harsh conditions.

- Performance Needs: Match cycle time and processing requirements (e.g., high-speed motion control vs. standard process logic).

- Budget: Balance upfront costs with long-term savings from reduced maintenance and energy efficiency.

7. Installation and Maintenance Notes

-

Safety: Follow EMC guidelines and ensure proper grounding to prevent interference.

-

Cooling: Maintain adequate airflow; avoid mounting in direct sunlight or high-temperature zones.

-

Software: Use ABB’s official tools (Automation Builder) for configuration and firmware updates.

-

Redundancy: Enable dual-port Ethernet for critical applications to prevent communication failures.

-

Maintenance: Schedule periodic health checks via built-in diagnostics; replace faulty modules immediately to avoid system-wide errors.