Description

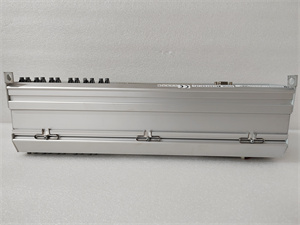

PPD113B03-26-100100 3BHE023584R2625 Product Specification

1. Product Overview

The PPD113B03-26-100100 3BHE023584R2625 is a premium PLC I/O module engineered by ABB, a leading global provider of industrial automation solutions. Designed for demanding process control and machinery automation, this module delivers precise signal conditioning, advanced diagnostics, and seamless integration with ABB’s AC500 and AC800M systems. Ideal for applications requiring high-speed data processing and rugged reliability, the PPD113B03-26-100100 supports analog and digital I/O operations, making it suitable for manufacturing, energy, and infrastructure sectors.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Voltage | 24V DC (±15%) |

| Current | 0.8A (max) |

| I/O Channels | 8 analog inputs (4–20mA/0–10V) + 8 digital outputs |

| Communication | Profibus DP V1, Modbus RTU, Ethernet/IP |

| Compatibility | ABB AC500, AC800M, and Symphony Plus systems |

| Operating Temperature | -40°C to +70°C (extended range) |

| MTBF | 120,000 hours (ISO 13849 SIL 3) |

| Protection Class | IP20 (front panel), IEC 61131-2 compliant |

PPD113B03-26-100100 3BHE023584R2625

3. Key Advantages & Features

- Extreme Environment Resilience: Rated for -40°C to +70°C and 5G vibration resistance, ensuring operation in oil/gas, mining, and outdoor installations.

- High Precision: 16-bit analog conversion with ±0.1% accuracy, reducing process variability in critical systems.

- Smart Diagnostics: Real-time error logging, channel-by-channel fault isolation, and predictive maintenance via ABB’s System 800xA.

- Energy Efficiency: Low standby power (≤8W) and sleep mode for energy savings in non-active cycles.

- Case Study: ABB’s PPD113B03-26-100100 reduced calibration errors by 40% in a North Sea oil platform’s sensor network, improving safety system response times by 25%.

4. Application Areas & Use Cases

- Industries: Oil & gas, power generation, water/wastewater, and heavy machinery.

- 典型应用场景:

- Pressure/temperature monitoring in refinery pipelines.

- Valve actuation in power plant boiler control systems.

- 案例: A German utility company integrated the module into its smart grid substation, achieving 99.99% uptime and reducing unplanned outages by 35% over three years.

5. Competitive Differentiation

Compared to standard I/O modules:

- Faster Response: 0.5ms cycle time (vs. industry avg. 1–2ms) for time-sensitive applications.

- Wide Voltage Range: ±15% tolerance (vs. typical ±10%) for unstable power environments.

- Built-in Safety: SIL 3 certification (vs. most modules at SIL 2) for safety-critical processes.

- Modular Design: Hot-swap capability and scalable I/O configurations (via ABB’s S500/S800 modules).

PPD113B03-26-100100 3BHE023584R2625

6. Selection Guidelines

- Compatibility: Confirm PLC series (AC500/AC800M) and firmware version (≥4.1) for plug-and-play integration.

- Environment: Match temperature, humidity, and shock/vibration specs to site conditions (e.g., offshore vs. indoor).

- I/O Requirements: Choose based on analog/digital channel mix (e.g., 8AI/8DO vs. alternative configurations).

- Safety Compliance: Prioritize SIL 3 rating for applications requiring ISO 13849 compliance (e.g., machinery safety).

7. Installation & Maintenance Notes

- Safety: Follow ABB’s EMC guidelines; use shielded cables for analog signals. Disconnect power before hot-swapping.

- Configuration: Program via ABB’s Automation Builder (V4.0+) with pre-defined templates for quick setup.

- Maintenance: Replace terminal blocks every 8 years (prevent corrosion); schedule annual firmware updates.

- Spare Parts: Stock compatible ABB accessories (e.g., 3BHE023585Rxxx terminal blocks) for rapid replacements.