Description

Product Description

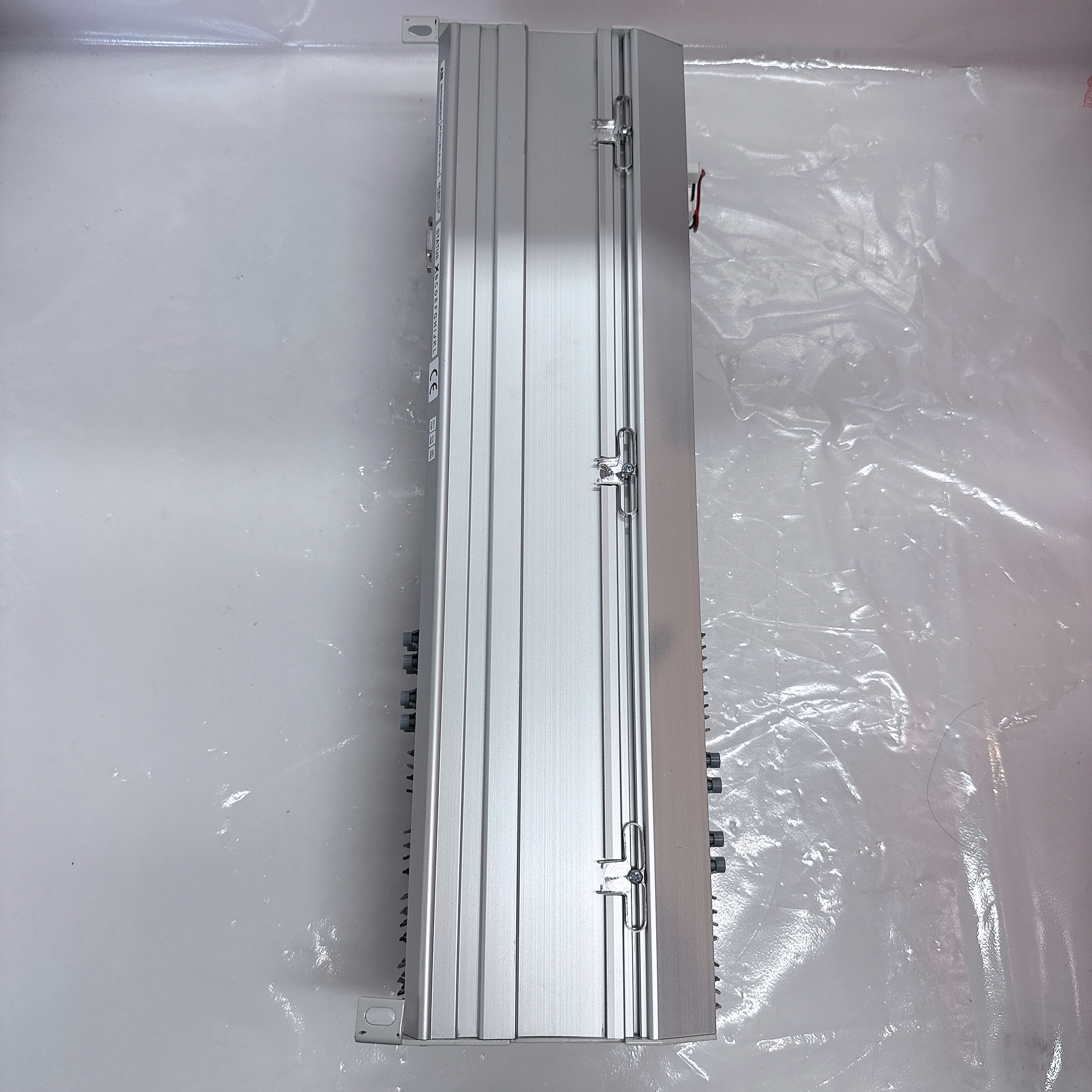

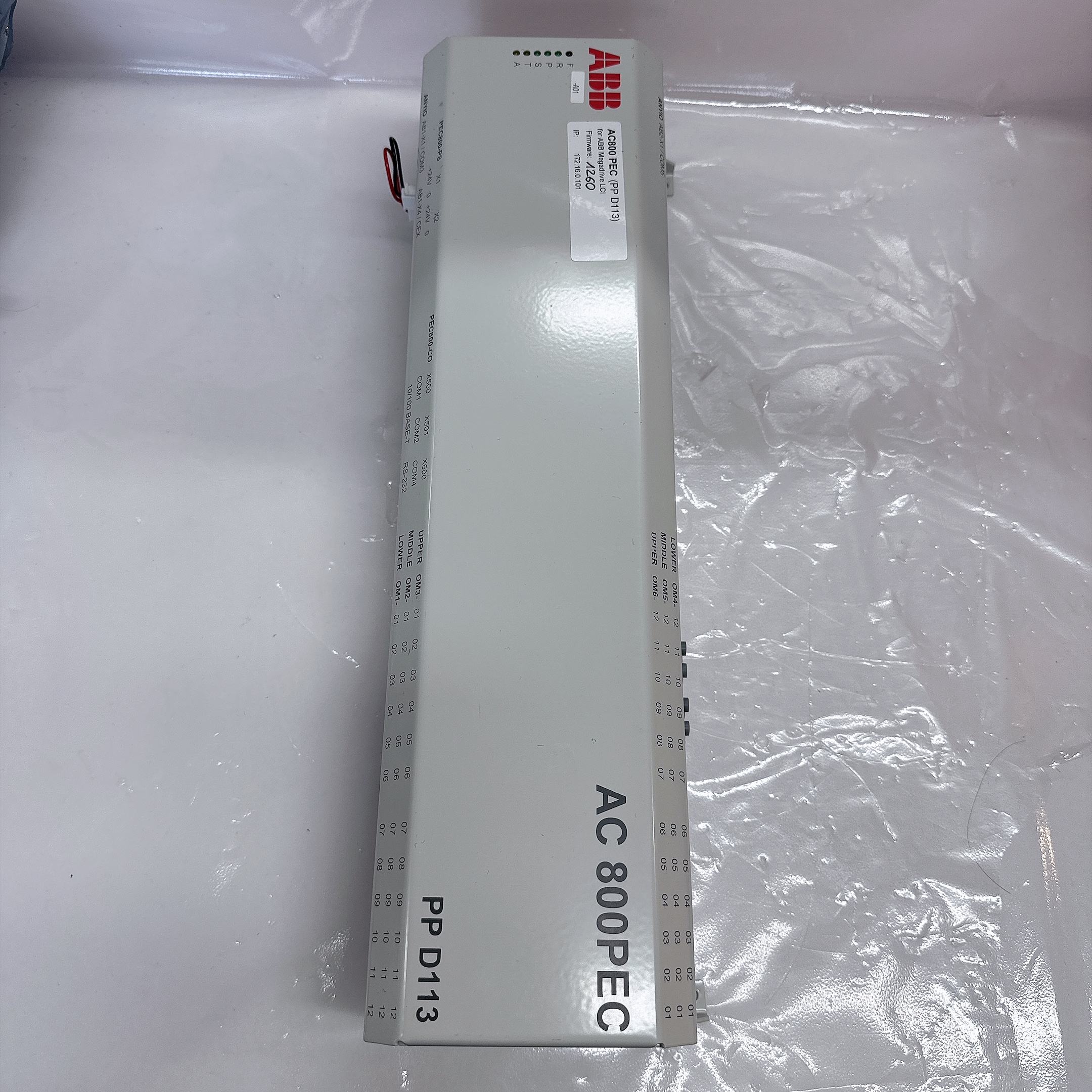

The ABB PPD113B03-26-100110 is a high-performance distributed I/O module designed for industrial process automation, part of ABB’s AC 800M control system. Engineered for reliable data acquisition and control in harsh environments, the PPD113B03-26-100110 features 16 isolated digital input channels (24 V DC) with surge protection, supporting fast response times (≤1 ms) for critical applications. Built with advanced diagnostics (LED status indicators) and redundant power supply (24 V DC ±20%), it ensures continuous operation in challenging conditions. Compatible with ABB’s Industrial IT System 800xA, the module offers seamless integration with PLCs, SCADA systems, and cloud platforms via Profibus DP/V1 or Ethernet/IP. Ideal for modular manufacturing lines, power plants, and oil & gas installations, the PPD113B03-26-100110 delivers precision control and scalability.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | PPD113B03-26-100110 |

| Brand | ABB |

| Type | Digital Input Module (16 channels) |

| Voltage | 24 V DC ±20% (power supply); 24 V DC (input) |

| Input Current | 4 mA per channel |

| Response Time | ≤1 ms (standard); ≤0.5 ms (fast mode) |

| Isolation | 500 V DC (channel-to-ground) |

| Communication | Profibus DP/V1 (9.6 kbps–12 Mbps), Ethernet/IP |

| Enclosure | 35 mm DIN rail mountable, IP20 (module), IP65 (with protective cover) |

| Operating Temperature | -40°C to +70°C |

| Dimensions | 100 x 100 x 50 mm (W x H x D) |

| Certifications | CE, UL, CSA, IEC 61131-2 |

PPD113B03-26-100110

Advantages and Features

- Rugged Reliability: Surge protection (600 V transient) and wide temperature range (-40°C to +70°C) ensure operation in extreme climates (e.g., Arctic oil rigs, desert solar farms).

- Modular Design: Hot-swap capability reduces downtime; expandable via ABB’s AC 800M I/O system (supports up to 1,024 modules per network).

- Advanced Diagnostics: Real-time channel status (LEDs) and fault detection (short circuit, open circuit) minimize troubleshooting time.

- Energy Efficiency: Low power consumption (≤3 W) and sleep mode reduce operational costs.

- Case Study: A German automotive plant reduced downtime by 30% using the PPD113B03-26-100110 for robotic welding line monitoring, achieving 99.8% uptime.

Application Areas and Use Cases

- Industries: Automotive manufacturing, power generation, oil & gas, chemical processing, and water treatment.

- Scenarios: Machine safety interlocks, conveyor control, sensor data acquisition, and emergency stop systems.

- Use Case: A U.S. wastewater treatment facility deployed 50+ PPD113B03-26-100110 modules to monitor 1,000+ level sensors, improving alarm response time by 40%.

Competitor Comparison

Compared to similar digital input modules:

- Higher Channel Density: 16 channels (vs. 8–12 in alternatives).

- Extended Temperature Range: -40°C to +70°C (vs. standard -25°C to +60°C).

- Faster Response: ≤1 ms (vs. 2–5 ms in legacy systems).

- Open Protocol Support: Native Profibus and Ethernet/IP (vs. limited proprietary protocols in some 竞品).

PPD113B03-26-100110

Selection Recommendations

- Environment: Choose the PPD113B03-26-100110 for outdoor or high-vibration settings (DIN rail mounting with shock resistance).

- Compatibility: Ensure alignment with ABB’s AC 800M or 第三方 PLCs (Profibus/Ethernet drivers available).

- Scalability: Pair with ABB’s PPD123 (analog output) or PPD133 (analog input) for full I/O system integration.

- Budget: Cost-effective ($200–$250) with 5-year MTBF (vs. 3–4 years in premium alternatives).

Precautions

- Installation: Secure DIN rail mounting; torque screws to 0.5–0.8 N·m.

- Wiring: Use 0.5–1.5 mm² shielded cables; terminate grounds per IEC 61000-5-2.

- Power: Verify 24 V DC stability (avoid voltage spikes >600 V).

- Software: Configure via ABB’s Control Builder M (latest version 5.1 SP3+).

- Safety: Disconnect power before replacing modules; wear ESD wrist straps.