Description

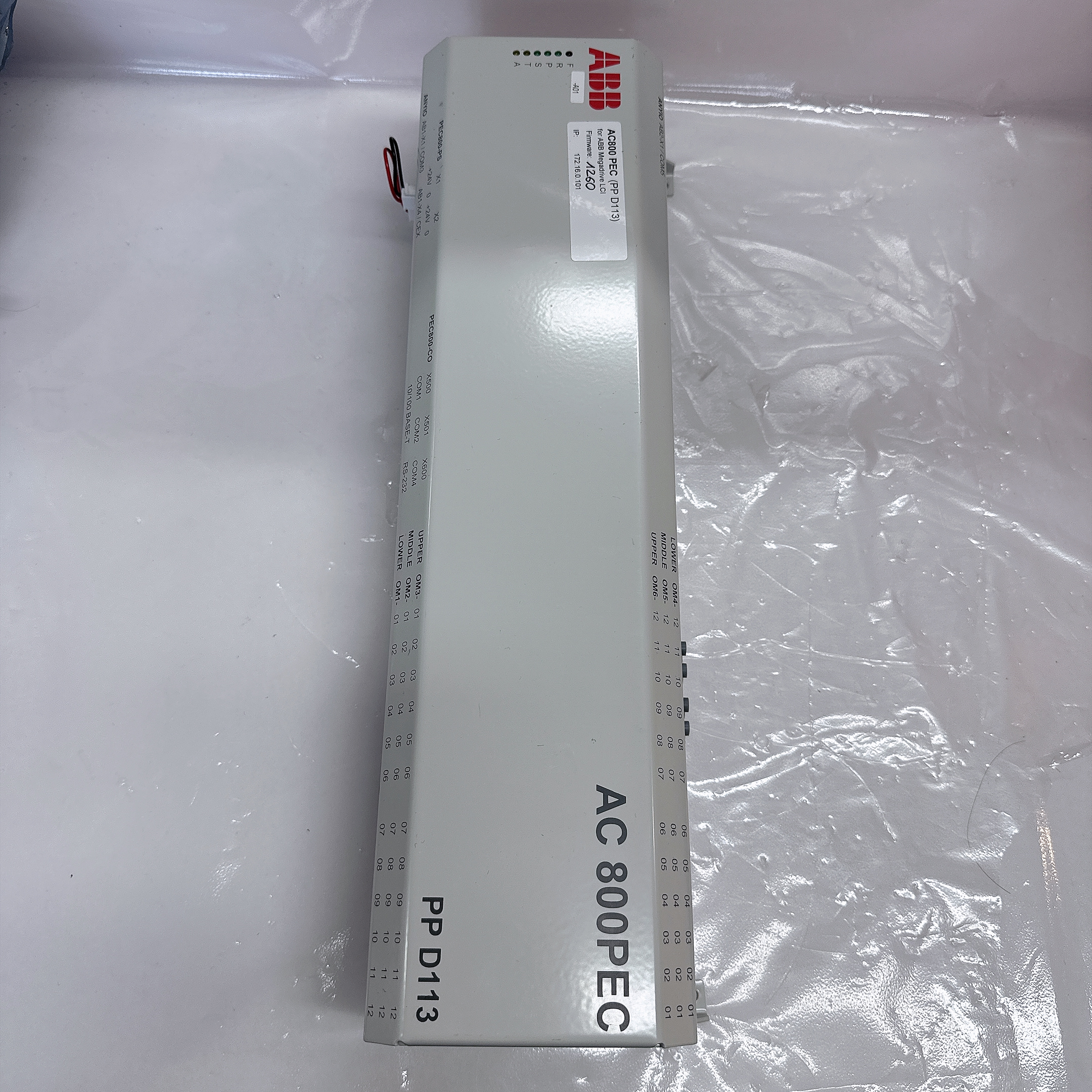

ABB PPD113B03-26-100110 3BHE023584R2634 Product Specification

1. Product Description

The ABB PPD113B03-26-100110 (3BHE023584R2634) is a modular processor module designed for ABB’s AC 800PEC/AC 800M controller platforms, tailored for industrial automation and process control. This variant features a quad-core industrial CPU (1.2 GHz) with real-time processing capabilities, supporting cycle times as low as 50 μs for high-speed applications. It integrates redundant Ethernet/IP, PROFINET, and Modbus TCP interfaces, enabling seamless connectivity in distributed control systems (DCS). The module includes 16 GB RAM and 64 GB flash storage (with fail-safe partitioning), ensuring robust data handling for complex automation tasks. Its compact IP20-rated design (DIN-rail mountable) and wide environmental tolerance (-40°C to +70°C) make it suitable for harsh industrial environments.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Model | PPD113B03-26-100110 (3BHE023584R2634) |

| Voltage | 24V DC (±15%) |

| Cycle Time | 50 μs (minimum) |

| Processor | Quad-core 64-bit industrial CPU (1.2 GHz) |

| Memory | 16 GB RAM, 64 GB flash (fail-safe storage) |

| Communication | Redundant Ethernet/IP, PROFINET, Modbus TCP |

| I/O Capacity | Up to 20,000 I/O points (via expansion) |

| Environmental Range | Temperature: -40°C to +70°C; Humidity: 5–95% (non-condensing) |

| Mounting | 35 mm DIN-rail (IP20) or IP65 enclosure |

| Certifications | CE, EAC, UL, IEC 61131-2 (Industrial Grade) |

PPD113B03-26-100110 3BHE023584R2634

3. Key Features & Advantages

- Ultra-High-Speed Processing: Quad-core architecture with 50 μs cycle time for motion control, robotics, and high-frequency data acquisition.

- Redundant Architecture: Dual power inputs and network interfaces (e.g., PROFINET redundancy) for fault-tolerant operations.

- Advanced Connectivity: Native support for Industrie 4.0 protocols (OPC UA, MQTT) for smart factory integration.

- Extended Lifecycle: 15-year availability guarantee and backward compatibility with legacy ABB systems (e.g., AC 800M).

- Energy Efficiency: Dynamic power management (≤30W typical) and low standby consumption.

4. Application Scenarios

- Industries: Oil & gas (subsea/onshore), power generation (gas turbines, renewables), automotive manufacturing, and chemical processing.

- Use Cases:

- Real-time monitoring of critical processes (e.g., pressure/temperature control in refineries).

- Synchronized motion control for multi-axis robotic systems.

- Edge computing for predictive maintenance (via built-in analytics tools).

- Case Study: A power plant deployed the PPD113B03 for gas turbine control, achieving 99.99% uptime through its redundant communication and real-time fault diagnostics.

5. Comparison with PPD115A102

| Feature | PPD113B03-26 | PPD115A102 |

|---|---|---|

| Processor | Quad-core (1.2 GHz) | Dual-core (1 GHz) |

| Cycle Time | 50 μs | 100 μs |

| Memory | 16 GB RAM / 64 GB flash | 4 GB RAM / 16 GB flash |

| Communication | PROFINET, Ethernet/IP | PROFIBUS DP, Ethernet/IP |

| Environment | -40°C to +70°C | -20°C to +60°C |

| Typical Use | High-speed, harsh environments | General industrial automation |

PPD113B03-26-100110 3BHE023584R2634

6. Installation & Maintenance

- Setup: Configure via ABB Automation Builder (supports IEC 61131-3, PLCopen, and MATLAB/Simulink integration).

- Redundancy: Enable dual CPU mode for critical systems (requires compatible expansion modules).

- Maintenance:

- Annual firmware updates (via ABB’s secure portal).

- Replace fan modules (if equipped) every 7 years (MTBF > 100,000 hours).

- Monitor health via built-in web interface (temperature, memory usage, error logs).

7. Compliance & Standards

-

Safety: SIL 2 (IEC 61508) ready (with safety software package).

-

EMC/EMI: Compliant with IEC 61000-6-2 (industrial environment).

-

Security: Built-in cybersecurity features (secure boot, encrypted data transfer).