Description

1. Product Description

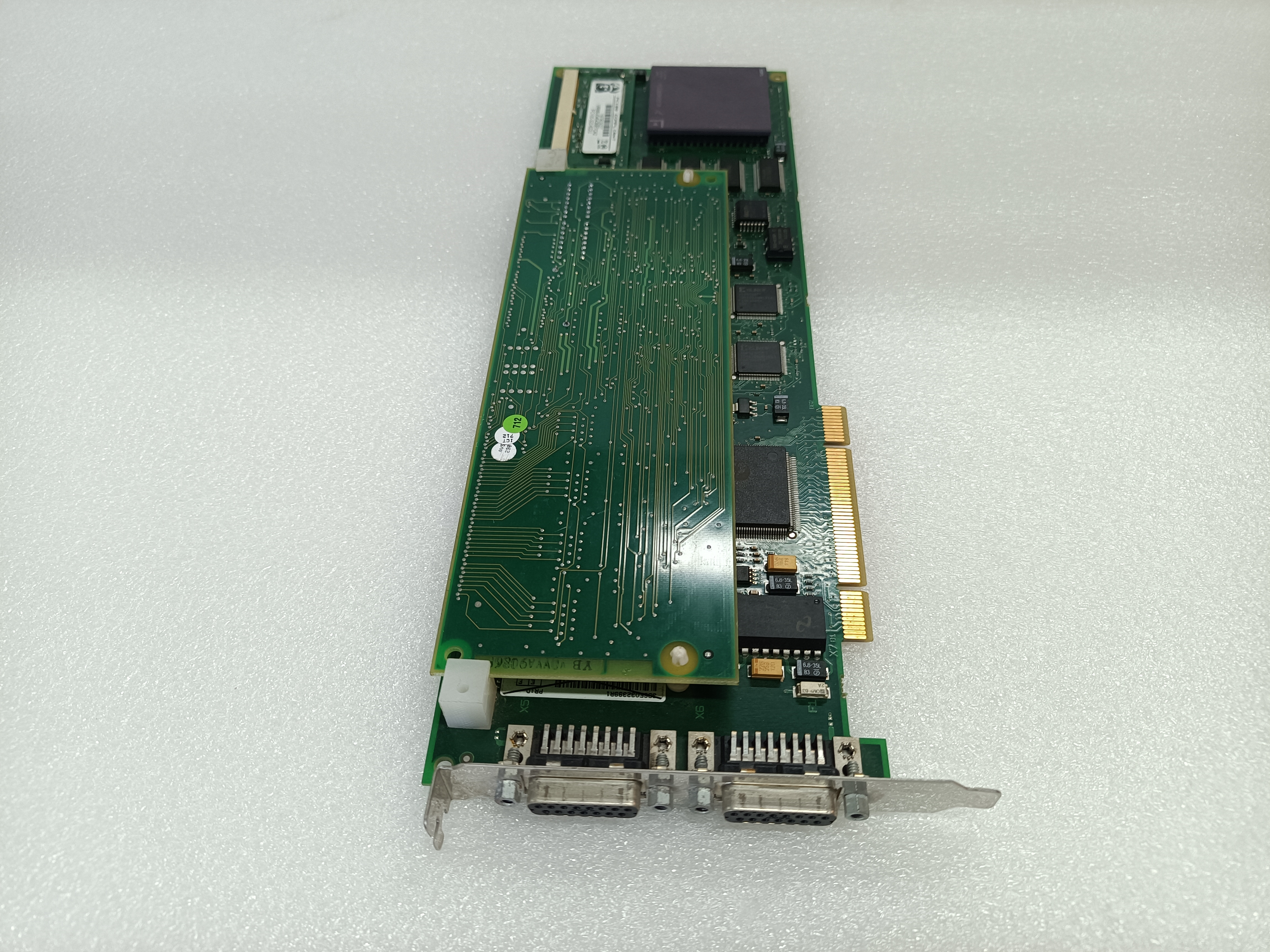

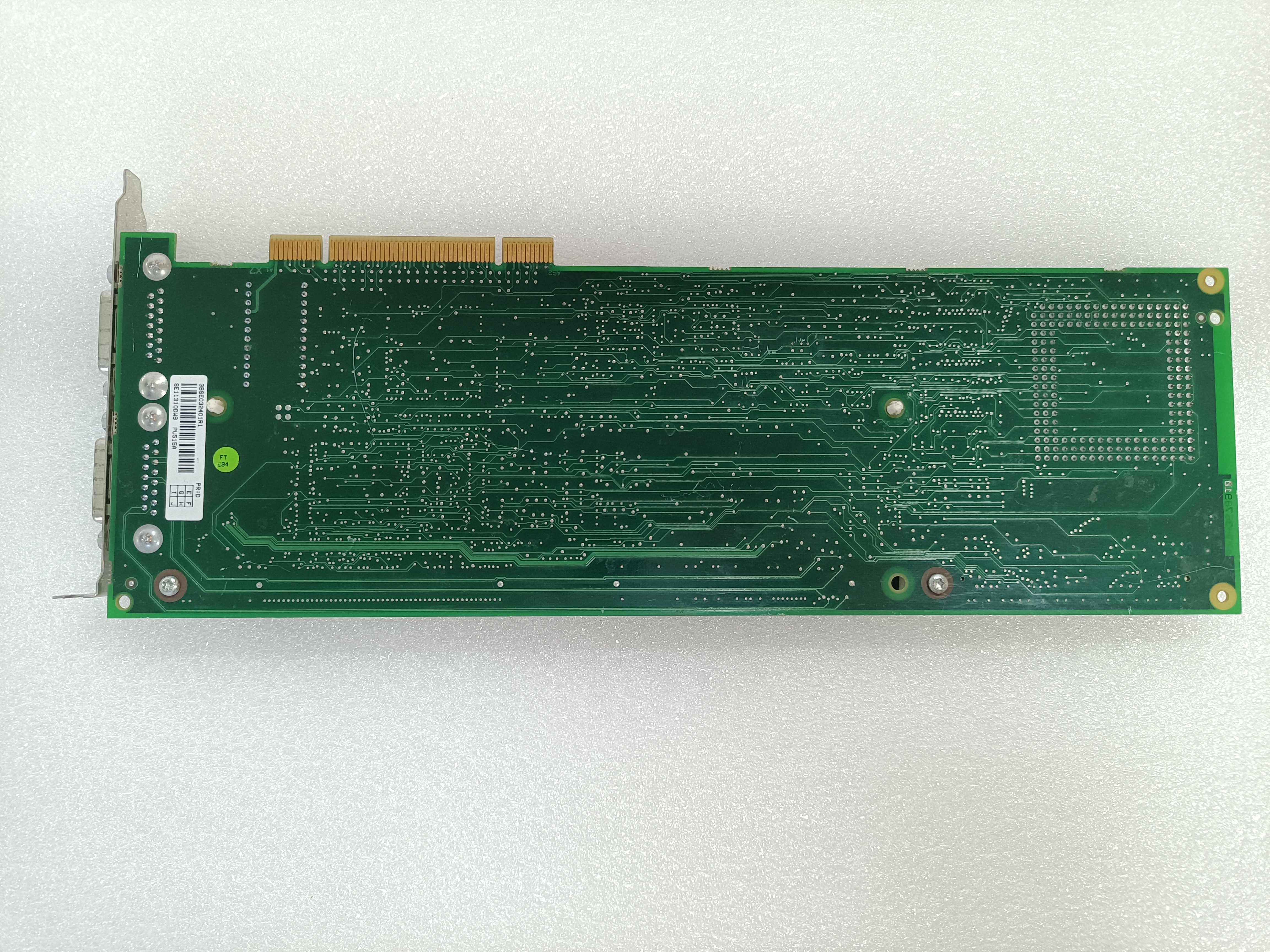

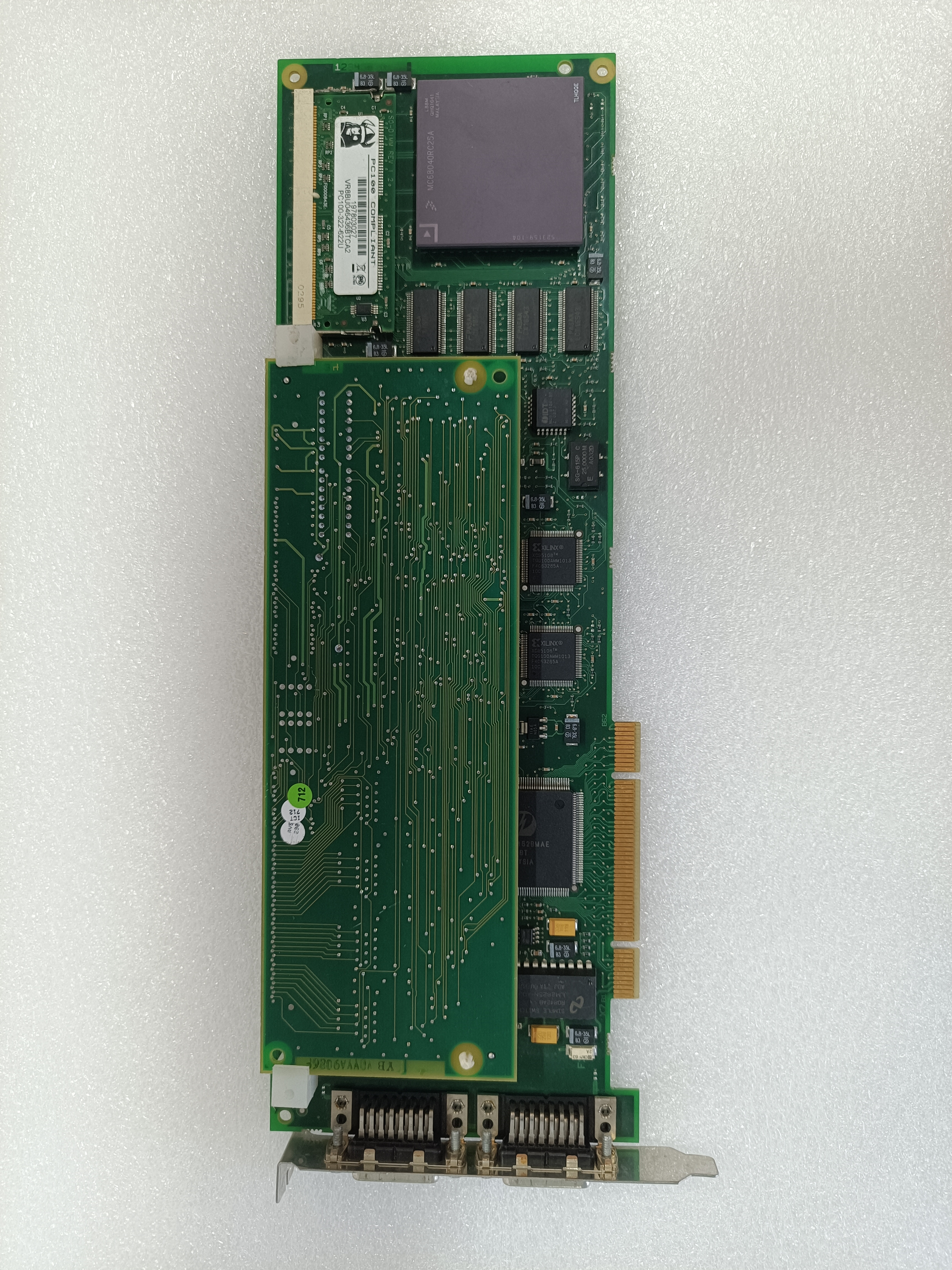

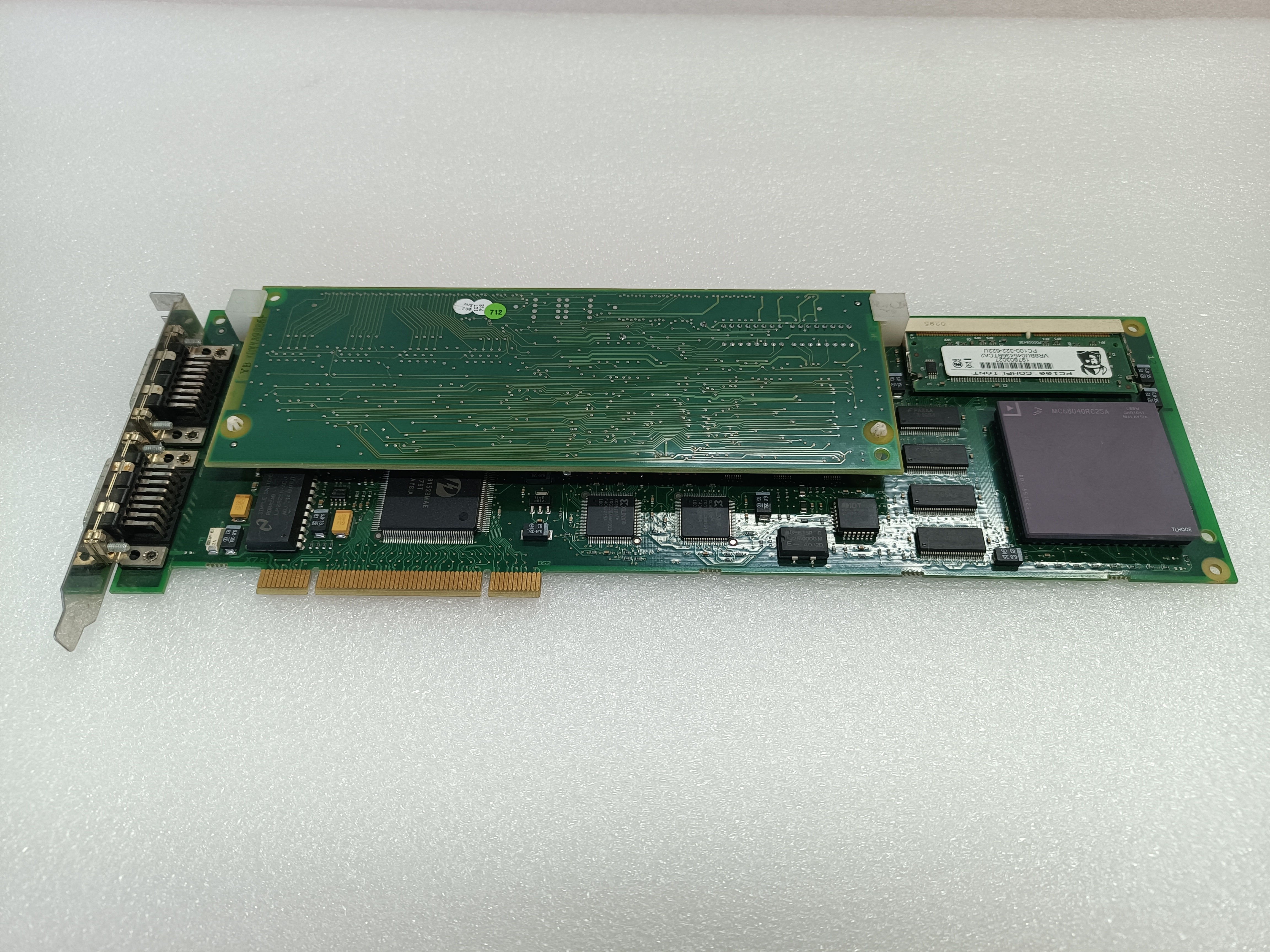

The ABB PU515A 3BSE032401R1 is a Real-Time Accelerator (RTA) board designed for ABB’s Advant OCS systems, including the Advant Station 500 series, to enhance real-time processing and communication in industrial automation. As a high-performance module, the PU515A 3BSE032401R1 offloads computational tasks from the main CPU, enabling faster data transfer and reduced latency in critical applications. It features a 32-bit/64-bit PCI/PCI-X interface (33 MHz/100/133 MHz), dual-channel MB300 communication (via CS503V1 module), and 16 MB RAM for handling complex control algorithms. With two 15-pin D-sub connectors, it integrates seamlessly with field devices, sensors, and actuators. The PU515A 3BSE032401R1 is ideal for industries requiring rapid data processing, such as power generation, manufacturing, and oil/gas, where real-time responsiveness is critical.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model | PU515A 3BSE032401R1 |

| Brand | ABB |

| Type | Real-Time Accelerator (RTA) Board |

| Interface | PCI/PCI-X (32-bit/64-bit, 33/100/133 MHz) |

| Communication | Dual-channel MB300 (via CS503V1 module) |

| Memory | 16 MB RAM |

| Connectors | 2×15-pin female D-sub |

| Voltage | 3.3V/5V (PCI bus-powered) |

| Dimensions | 34.2 × 25.9 × 7.42 cm (W×H×D) |

| Weight | ~0.4 kg (module) / ~3.6 kg (packaged) |

| Compatibility | ABB Advant OCS systems (Advant Station 500) |

| Environment | -25°C to +60°C, industrial-grade protection |

| RoHS Compliance | Yes |

PU515A 3BSE032401R1

3. Advantages and Features

- Real-Time Performance: Reduces CPU load by 40–60% for faster control loops (e.g., PID algorithms, HMI updates).

- Dual-Channel Communication: Supports redundant MB300 networks for reliable data exchange with field devices.

- Flexible Integration: Compatible with 32-bit/64-bit PCI slots (retrofit-friendly for legacy systems).

- Compact Design: Space-saving form factor (34.2×25.9×7.42 cm) for modular control cabinets.

- Industrial Grade: Operates in harsh environments (-25°C to +60°C) with EMI/RFI protection.

- Hot-Swap Capability: Replaceable without system shutdown (requires compatible backplane).

Case Study: A power plant upgraded its boiler control system with PU515A 3BSE032401R1, achieving 20% faster response times in turbine speed regulation, reducing downtime by 15%.

4. Application Areas and Use Cases

- Industries: Power generation, oil/gas, manufacturing, water treatment.

- Scenarios: Real-time data acquisition, PLC/HMI acceleration, distributed control systems (DCS).

- Use Case: A chemical plant used the PU515A 3BSE032401R1 to manage 500+ analog inputs in a distillation unit, enabling sub-10ms data processing for precise temperature control.

5. Competitor Comparison

Compared to generic RTAs:

- Native Compatibility: Optimized for ABB Advant OCS, ensuring plug-and-play integration (vs. generic PCI cards requiring custom drivers).

- Redundancy Support: Dual MB300 channels for fault tolerance (vs. single-channel alternatives).

- Performance Density: 16 MB RAM + dedicated processing cores vs. 8–12 MB in standard modules.

- Long-Term Support: Backed by ABB’s lifecycle management (vs. short-lived third-party solutions).

PU515A 3BSE032401R1

6. Selection Recommendations

- System Compatibility: Verify compatibility with ABB Advant OCS (e.g., Advant Station 500, AC 800M).

- Processing Needs: Choose PU515A for mid-scale systems (500–1,000 I/O points); upgrade to PU518/PU519 for larger installations.

- Interface Requirements: Ensure PCI/PCI-X slots are available (avoid USB-dependent modules for deterministic performance).

- Budget: Balances cost ($500–$1,500) with industrial-grade reliability (vs. premium-brand RTAs costing 20–30% more).

7. Precautions

- Installation:

- Use anti-static gear; avoid bending PCI pins.

- Securely fasten the module to the backplane (torque screws to 0.5 N·m).

- Power Management: Ensure stable 3.3V/5V supply (voltage spikes >10% may damage the board).

- Maintenance:

- Clean dust from vents quarterly (use compressed air).

- Replace thermal paste every 3 years (for prolonged high-temperature use).

- Software: Update firmware via ABB’s System 800xA Toolbox (critical for security patches).