Description

1. Product Description

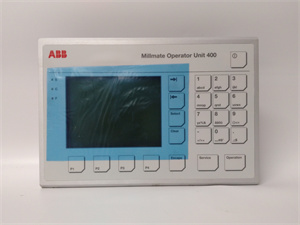

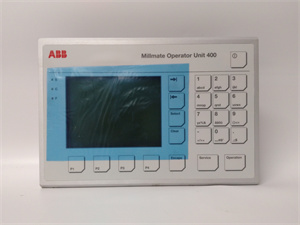

The ABB PXAH401 3BSE017235R1 is a high-performance Human-Machine Interface (HMI) operator unit designed for industrial automation and process control systems, particularly ABB’s Mill Mate platform for papermaking and manufacturing. This 10.1-inch touchscreen module serves as a centralized interface for real-time monitoring, data visualization, and operator interaction. With an 800 x 600 pixel resolution and IP65 protection, the PXAH401 3BSE017235R1 withstands harsh environments (–20°C to +60°C) while delivering intuitive control for processes like machine speed adjustment, alarm management, and quality metric tracking. Its modular design supports seamless integration with ABB’s PLC and DCS systems, making it ideal for industries such as paper production, energy, and manufacturing.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | HMI Operator Unit (Mill Mate 400) |

| Display | 10.1-inch resistive touchscreen |

| Resolution | 800 x 600 pixels |

| Operating Temperature | –20°C to +60°C (storage: –40°C to +85°C) |

| Protection Rating | IP65 (dust and water resistance) |

| Power Supply | 24V DC (±10%) |

| Dimensions | 264 mm × 176 mm × 63 mm |

| Weight | 2.3 kg |

| Communication | Serial/ethernet (compatible with ABB PLC/DCS) |

| Features | Multilingual support, alarm management, real-time data logging |

PXAH401 3BSE017235R1

3. Advantages and Features

- Robust Design: IP65 rating and wide temperature range ensure reliability in dusty, wet, or extreme-temperature settings.

- Intuitive Interface: 10.1-inch touchscreen with high visibility (80° viewing angle) for operator-friendly control.

- Modular Flexibility: Easy expansion via ABB’s control system architecture; hot-swap capability for quick maintenance.

- Advanced Functionality: Supports process visualization (e.g., sheet tension in papermaking), alarm acknowledgment, and remote diagnostics.

- Case Study: A paper mill reduced operator error by 25% using the PXAH401 3BSE017235R1 to centralize machine status monitoring and parameter adjustments, improving production consistency.

4. Application Areas and Case Studies

- Paper Manufacturing: Papermachine control (tension, speed, quality).

- Energy: Power plant monitoring and HVAC control.

- Manufacturing: Assembly line optimization and robotic system management.

- Case Study: A petrochemical facility deployed the PXAH401 3BSE017235R1 to monitor 50+ process variables in a distillation unit. The HMI’s real-time data dashboards and alarm prioritization reduced downtime by 20%.

5. Competitor Comparison

Compared to similar industrial HMIs:

- Larger Display: 10.1 inches (vs. 7–8 inches for some competitors).

- Higher Protection: IP65 (vs. IP54 for basic models), suitable for washdown environments.

- ABB Ecosystem Integration: Native compatibility with Mill Mate and AC500 systems, minimizing configuration effort.

PXAH401 3BSE017235R1

6. Selection Recommendations

- Environment: Choose the PXAH401 3BSE017235R1 for harsh conditions (IP65, wide temp range).

- Integration: Ensure compatibility with ABB’s control platforms (e.g., Mill Mate, AC500).

- Functionality: Opt for this model if requiring large-screen visualization, alarm management, or multilingual support.

7. Precautions

-

Installation: Mount vertically with 50 mm clearance for ventilation. Use shielded cables for communication.

-

Power: Verify 24V DC supply stability; avoid voltage spikes.

-

Maintenance: Clean the touchscreen with a dry cloth. Update firmware (latest: V3.2+) annually.

-

Safety: Follow IEC 61010-1 for electrical safety. Calibrate the touchscreen every 2 years.