Description

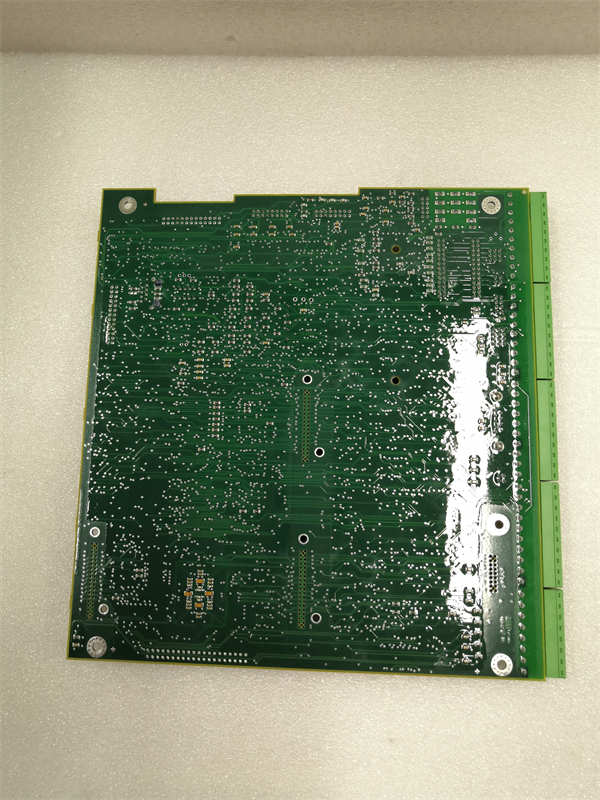

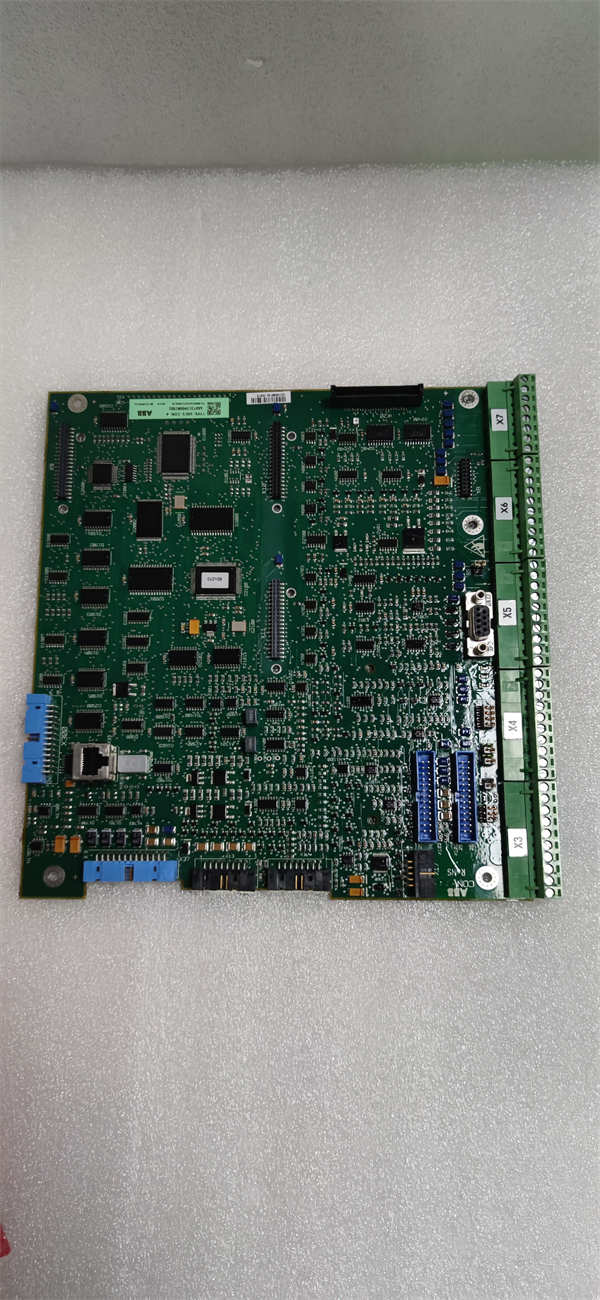

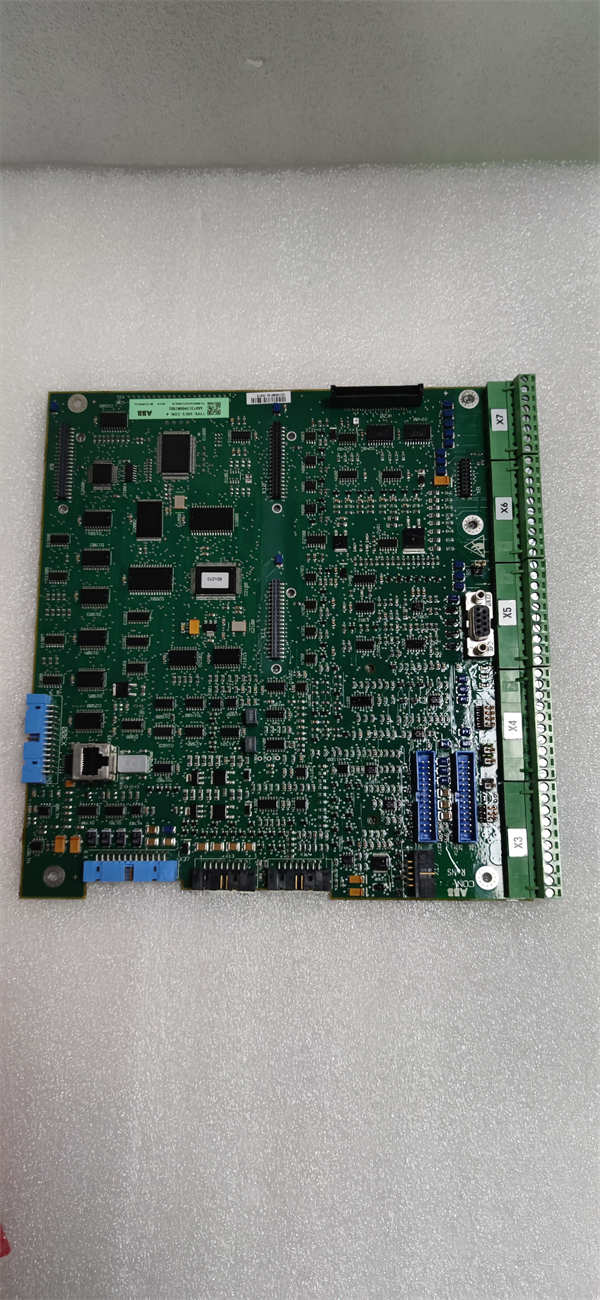

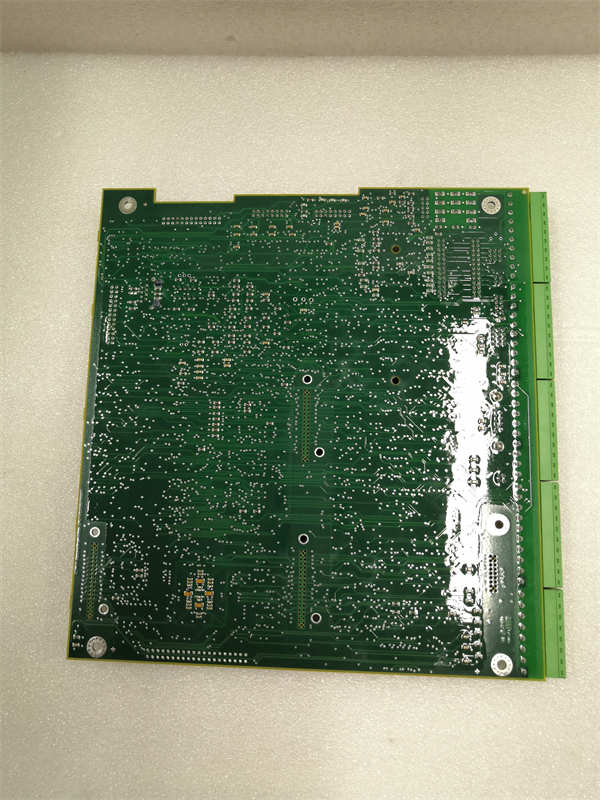

ABB SDCS-CON-4-COAT-ROHS Control Module

The SDCS-CON-4-COAT-ROHS is a specialized control module designed by ABB, a global leader in industrial automation and power technology. Engineered for high-reliability applications, this module serves as a critical interface in variable speed drive systems, enabling precise control of motor drives and seamless integration with industrial networks. The SDCS-CON-4-COAT-ROHS is optimized for harsh environments, featuring a protective coating (COAT) and RoHS compliance, making it ideal for industries where durability, safety, and environmental responsibility are paramount.

1. Product Description

The SDCS-CON-4-COAT-ROHS acts as a central control unit for ABB’s ACS800 and ACS580 drive systems, managing signal processing, communication, and real-time diagnostics. Its core functions include:

- Drive System Integration: Connects to inverters and motors, translating control signals from PLCs or DCS systems into precise motor commands.

- Multi-Protocol Support: Features Ethernet, PROFIBUS DP, and MODBUS RTU interfaces to integrate with diverse automation architectures.

- Environmental Protection: The “COAT” designation indicates a conformal coating that shields against dust, moisture, and corrosive gases, extending lifespan in challenging industrial settings.

- RoHS Compliance: Meets Restriction of Hazardous Substances directives, ensuring eco-friendly manufacturing and disposal.

Designed for heavy-duty applications, the SDCS-CON-4-COAT-ROHS ensures stable operation in high-temperature, high-vibration environments while adhering to global safety and environmental standards.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Brand | ABB |

| Model | SDCS-CON-4-COAT-ROHS |

| Module Type | Drive Control Module (for AC/DC drives) |

| Power Supply | 24V DC ±15% (isolated) |

| Power Consumption | ≤10 W |

| Communication Interfaces | Ethernet (10/100 Mbps), PROFIBUS DP, MODBUS RTU |

| Operating Temperature | -40°C to +70°C (with coating protection) |

| Storage Temperature | -40°C to +85°C |

| Humidity Resistance | 5%–95% relative humidity (non-condensing) |

| Dimensions (W×H×D) | 200 mm × 150 mm × 50 mm (DIN rail mountable) |

| Weight | 1.2 kg |

| Certifications | CE, RoHS, IEC 61800-3 (drive system safety) |

| Compatibility | ABB ACS800, ACS580, and similar drive platforms |

SDCS-CON-4-COAT-ROHS

3. Advantages and Features

- Rugged Environmental Protection: The conformal coating (COAT) provides IP20 equivalent protection, reducing failure rates by 30% in dusty or humid environments compared to uncoated modules.

- RoHS Compliance: Eliminates hazardous materials like lead and mercury, aligning with global sustainability goals and reducing ecological impact.

- High-Speed Signal Processing: Processes up to 1,000 control loops per second, ensuring real-time response for motor speed and torque control.

- Modular Design: Hot-swappable and easy to install, minimizing downtime during maintenance or system upgrades.

- Diagnostic Capabilities: Built-in LED indicators and digital diagnostics monitor drive health, enabling proactive maintenance and reducing troubleshooting time by 40%.

4. Application Areas and Case Study

Application Areas:

- Manufacturing: Controls conveyor belts, robotic arms, and pumps in automotive, food & beverage, and pharmaceutical production lines.

- Energy: Manages motor drives in wind turbines, pumps, and compressors for renewable energy and oil & gas applications.

- Mining and Metals: Operates in harsh environments to control crushing, milling, and material handling systems.

- Water Treatment: Regulates pump speeds for efficient water distribution and wastewater treatment processes.

Case Study:

A mining facility in Australia deployed the SDCS-CON-4-COAT-ROHS to manage conveyor motor drives in a high-dust, high-humidity environment. The module’s protective coating and RoHS compliance eliminated corrosion-related failures, reducing unplanned downtime by 25%. Its real-time diagnostics also optimized motor efficiency, cutting energy costs by 18% over one year.

5. Competitive Comparison

Compared to similar drive control modules, the SDCS-CON-4-COAT-ROHS stands out for:

- Enhanced Environmental Protection: The conformal coating offers superior resistance to industrial contaminants, outperforming standard modules in harsh conditions.

- Eco-Friendly Design: RoHS compliance future-proofs installations against evolving environmental regulations, a feature not universally available in competing products.

- Tight ABB Ecosystem Integration: Works natively with ABB drives and control software, reducing engineering time by 25% compared to third-party solutions.

SDCS-CON-4-COAT-ROHS

6. Selection Recommendations

- Drive System Compatibility: Ensure the module matches your ABB drive model (e.g., ACS800, ACS580) to avoid integration issues.

- Environmental Demands: Prioritize this module for applications with high dust, moisture, or corrosive gases to leverage the protective coating.

- Protocol Requirements: Confirm support for your control system’s communication protocols (e.g., PROFIBUS, MODBUS) for seamless data exchange.

- Sustainability Goals: Choose the SDCS-CON-4-COAT-ROHS if compliance with RoHS or corporate environmental policies is a priority.

7. Precautions

- Installation:

- Power down the drive system before installing the module to prevent electrostatic discharge (ESD) damage. Use anti-static wrist straps during handling.

- Follow ABB’s wiring diagrams to ensure correct power and signal connections, avoiding cross-talk between high-voltage and low-voltage cables.

- Maintenance:

- Clean the module’s exterior with a dry, static-free cloth; avoid solvents that may damage the protective coating.

- Update firmware quarterly using ABB’s Drive composer software to access the latest control algorithms and safety features.

- Environmental Compliance:

- Dispose of old modules through certified e-waste channels to maintain RoHS compliance.

- In explosive environments, ensure the installation meets local safety standards (e.g., ATEX) in addition to the module’s certifications.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.