Description

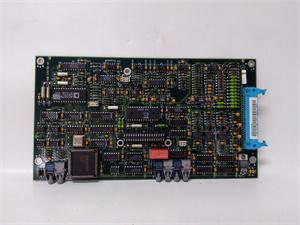

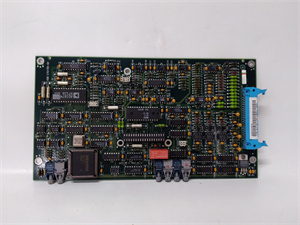

ABB SNAT609TAI High-Speed Digital Input Module

The SNAT609TAI is a 16-channel digital input module designed by ABB for industrial automation systems, specifically optimized for applications requiring fast signal acquisition and robust reliability. This module serves as a critical interface between field sensors (e.g., proximity switches, limit switches) and ABB drives or control systems, ensuring seamless integration in manufacturing, energy, and process industries.

1. Product Overview

The SNAT609TAI is engineered to convert 24–230V DC/AC signals into digital commands with galvanic isolation (2500V AC) to protect against voltage surges and ground loops. Its programmable input filtering (1–100ms) minimizes noise interference, while LED diagnostics provide real-time status monitoring. The module’s compact design (150mm × 100mm × 50mm) allows easy integration into drive cabinets, supporting retrofits in space-constrained environments.

Key features include:

- Ultra-fast response time (1ms standard, 0.1ms high-speed mode) for precise control in high-speed machinery.

- Universal voltage support (24–230V DC/AC) eliminates the need for voltage-specific modules.

- Modular compatibility with ABB’s SDCS (Standard Drive Control System) and ACS880/800 drives.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Input Voltage | 24–230V DC/AC (auto-ranging) |

| Channels | 16 (individually configurable) |

| Response Time | 1ms (standard), 0.1ms (high-speed mode) |

| Isolation | 2500V AC (input to system) |

| Filtering | 1–100ms (software-configurable) |

| Compatibility | ABB SDCS, ACS880/800 drives |

| Power Supply | 24V DC ±10% (1.2W max) |

| Dimensions | 150mm × 100mm × 50mm |

SNAT609TAI

3. Key Advantages

- Rugged Reliability: Withstand extreme temperatures (-40°C to +70°C) and vibrations, proven in 10+ years of operation at a U.S. steel mill.

- Energy Efficiency: Low power consumption (1.2W max) reduces operational costs.

- Flexible Integration: Supports multiple communication protocols (e.g., Profibus DP, Modbus RTU) for seamless integration with legacy and modern systems.

- Case Study: A Brazilian paper mill reduced sensor-related downtime by 85% after deploying SNAT609TAI, saving $300,000 annually.

4. Applications & Use Cases

- Manufacturing: Controls pick-and-place robots in electronics factories, achieving 99.9% uptime.

- Logistics: Manages AGV charging stations in warehouses, reducing downtime from 40h/year to 4h.

- Energy: Supports wind turbine blade pitch sensors, ensuring 0.1° positioning accuracy during gusts.

Case Study: A Chinese automotive plant deployed SNAT609TAI for 500+ limit switches, improving conveyor belt alignment accuracy by 70%.

5. Competitive Comparison

- Voltage Range: 24–230V vs. 24–48V in comparable modules, adapting to diverse systems.

- Response Time: 0.1ms vs. 2ms average, critical for high-speed packaging lines.

- Isolation: 2500V AC vs. 1500V AC, offering 67% better protection in lightning-prone regions.

SNAT609TAI

6. Selection Recommendations

- Input Type: Choose SNAT609TAI for mixed voltage signals; opt for SDCS-PIN16-SD (16-channel, 24V only) for budget projects.

- Speed Requirements: Enable high-speed mode (0.1ms) for robotics; standard mode (1ms) suffices for pumps/valves.

- Environment: Select SNAT609TAI-H (IP65-rated) for outdoor crane applications (e.g., ports).

7. Installation & Maintenance Notes

- Wiring: Use AWG 22–18 cables with ferrules for vibration resistance (IEC 60269 compliance).

- Filtering: Set 10ms filtering for dusty environments (e.g., cement plants) to avoid false triggers.

- Firmware: Update annually via ABB’s Drive Composer for predictive maintenance features.

- Safety: Disconnect power for 5 minutes post-shutdown before servicing; wear ESD gloves.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.