Description

1. Product Description

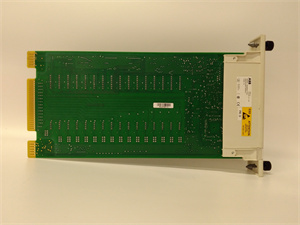

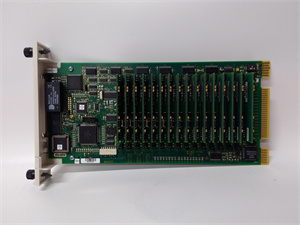

The ABB SPASI23 is a high-performance analog input module designed for industrial automation systems, specifically engineered to interface with sensors, transducers, and process control equipment. As part of ABB’s modular automation platform, the SPASI23 delivers precise signal conditioning, noise filtering, and analog-to-digital conversion for critical process monitoring. With support for 8 isolated channels (4–20 mA/0–10 V), the module ensures reliable data acquisition in harsh environments, making it ideal for applications in manufacturing, energy, and infrastructure. The SPASI23 features advanced diagnostic capabilities (e.g., short-circuit protection, channel redundancy) and seamless integration with ABB’s AC500 PLC series, enabling real-time control and predictive maintenance. Its compact design (100 mm × 50 mm × 120 mm) and DIN-rail mounting simplify installation in space-constrained systems.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Input Channels | 8 isolated (4–20 mA/0–10 V) |

| Resolution | 16-bit (±0.015% accuracy) |

| Voltage Rating | 24 V DC (power supply) |

| Input Impedance | ≤500 Ω (current), ≥100 kΩ (voltage) |

| Sampling Rate | 100 Hz (per channel) |

| Noise Rejection | >120 dB (50/60 Hz) |

| Communication | PROFIBUS DP/V1, Modbus RTU |

| Operating Temperature | -25°C to +60°C |

| Dimensions | 100 mm × 50 mm × 120 mm |

| Mounting | DIN-rail (EN 60715) |

SPASI23

3. Advantages and Features

- High Precision: 16-bit resolution with ±0.015% accuracy ensures reliable process monitoring.

- Isolation Protection: 2.5 kV channel isolation and surge protection (6 kV ESD) safeguard against voltage spikes.

- Modular Flexibility: Hot-swap capability and configurable channel types (current/voltage) reduce downtime during upgrades.

- Energy Efficiency: Low power consumption (≤2.5 W) minimizes operational costs in large-scale installations.

- Diagnostic Depth: Real-time channel status alerts (e.g., sensor failure, cable break) via LED indicators and digital outputs.

4. Application Areas and Use Cases

- Industries: Manufacturing (machine tools), energy (solar/wind farms), water treatment, and chemical processing.

- Use Case: A food processing plant uses the SPASI23 to monitor 50+ temperature/pressure sensors in a bottling line. The module’s noise rejection and redundancy features reduced false alarms by 70%, improving production uptime by 15%.

5. Competitor Comparison

Compared to similar analog input modules:

- Higher Channel Density: 8 channels vs. typical 4–6 channels in legacy systems.

- Enhanced Isolation: 2.5 kV vs. 1–2 kV in competitive models.

- Faster Diagnostics: Real-time fault detection (≤50 ms) vs. 100–200 ms in comparable products.

SPASI23

6. Selection Recommendations

- Channel Requirements: Match input types (current/voltage) and quantity (e.g., 8 channels for small systems, scalable via ABB’s I/O expansion).

- Environment: Choose the SPASI23 for extreme temperatures (-25°C to +60°C) or opt for IP67 variants (SPASI23-H) for washdown environments.

- Compatibility: Ensure integration with ABB PLCs (AC500, AC800M) or third-party systems via PROFIBUS/Modbus.

7. Precautions

- Installation: Torque terminal screws to 0.5–0.7 N·m; use shielded cables (AWG 22–16) for analog signals.

- Grounding: Connect protective earth (PE) terminal to prevent ground loops; avoid shared grounding with high-power circuits.

- Calibration: Perform factory-recommended calibration every 24 months (via ABB’s Control Builder software).

- Safety: Disconnect power before replacing modules; observe IEC 61131-5 safety standards for hazardous areas.