Description

1. Product Description

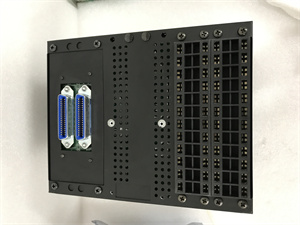

The GE Fanuc SR489-P5-HI-A20-E is a high-speed counter module designed for GE Fanuc’s Series 90-70/90-30 PLC systems, specialized in industrial automation and motion control applications. As a key component of the IC698 family, the SR489-P5-HI-A20-E supports up to 4 independent counter channels with 24 VDC differential inputs, enabling precise position tracking, speed monitoring, and event counting in machinery and production lines. It features a maximum counting frequency of 500 kHz (quadrature) / 1 MHz (single-phase) and integrates advanced functions like index input, direction control, and preset/output compare. The module includes screw-terminal connectors for easy wiring and is compatible with GE’s Proficy Machine Edition software for configuration and diagnostics. Its compact design (1.6” width) and DIN rail mounting make it suitable for space-constrained environments.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Brand/Model | GE Fanuc SR489-P5-HI-A20-E |

| Power Supply | 5 VDC (from PLC backplane), 24 VDC (input) |

| Channels | 4 independent counter channels |

| Input Type | 24 VDC differential (Line Driver/TTL) |

| Counting Modes | Single-phase, quadrature (x1, x2, x4), index |

| Max Frequency | 1 MHz (single-phase), 500 kHz (quadrature) |

| Preset/Compare Outputs | 4 discrete outputs (24 VDC, 0.5 A) |

| Memory | 16 KB for program storage |

| Compatibility | GE Fanuc Series 90-70 (IC697), 90-30 (IC693) PLCs |

| Operating Temperature | 0°C to 55°C |

| Dimensions | 1.6” W x 3.9” H x 3.6” D (40.6 x 99.1 x 91.4 mm) |

SR489-P5-HI-A20-E

3. Advantages and Features

- High-Speed Performance: Supports up to 1 MHz counting (single-phase), 30% faster than standard industrial counter modules.

- Multi-Channel Flexibility: 4 independent channels with configurable scaling (1–65535 pulses/revolution).

- Integrated Diagnostics: LED indicators for power, channel status, and error codes (e.g., over-range, input loss).

- Easy Integration: Plug-and-play compatibility with GE’s PLC backplane; no additional modules required for quadrature decoding.

- Reliability: Industrial-grade design (IP20 protection) with surge protection (2.5 kV isolation) and EMC/EMI shielding.

- Case Study: A European packaging plant reduced downtime by 20% using the SR489-P5-HI-A20-E for bottle count verification, achieving 99.99% accuracy at 200 bottles/minute.

4. Application Areas and Application Cases

- Application Areas: Manufacturing (conveyor systems, robotics), automotive (assembly lines), packaging (labeling machines), and material handling.

- Application Case: A U.S. automotive factory deployed the SR489-P5-HI-A20-E in robot arm positioning systems. The module’s quadrature counting (x4 mode) enabled ±0.1 mm precision, improving production throughput by 15% while reducing scrap rates.

5. Competitor Comparison

Compared to comparable counter modules (e.g., Allen-Bradley 1771-CNBR), the SR489-P5-HI-A20-E offers native integration with GE’s Series 90 PLC ecosystem, eliminating adapter costs. Its 4-channel design (vs. 2–3 channels in 竞品) and higher maximum frequency (1 MHz vs. 500 kHz) make it ideal for multi-axis applications requiring simultaneous high-speed counting.

SR489-P5-HI-A20-E

6. Selection Recommendations

- Channel Requirements: Choose the SR489-P5-HI-A20-E (4 channels) for multi-axis systems; opt for SR485 (2 channels) for simpler setups.

- Frequency Needs: Ensure the module’s 1 MHz (single-phase) capability matches your sensor/output frequency (e.g., encoders, proximity switches).

- PLC Compatibility: Verify PLC series (Series 90-70/90-30) and backplane version (e.g., IC697CHS790 for 90-70).

- Environment: Check temperature range (0°C–55°C) and mounting (DIN rail vs. panel).

7. Precautions

- Installation: Follow GE’s wiring guidelines (Publication 698-100) to avoid EMI (shielded cables for input signals).

- Power Management: Ensure stable 24 VDC input (±10% tolerance) and separate power for high-current outputs.

- Calibration: Use GE’s Proficy software to configure scaling factors and reset counters during system startups.

- Maintenance: Inspect terminal connections annually; replace modules if LED error codes (e.g., CH1 ERR) persist.

- Safety: Disconnect power before replacing the module; avoid exceeding 30 VDC on input/output terminals.