Description

1. Product Description

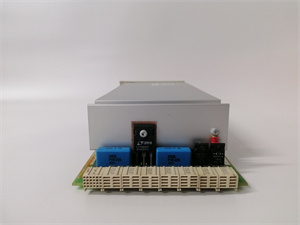

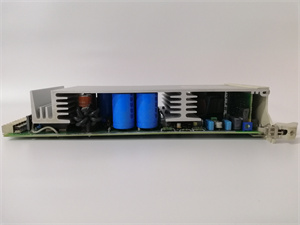

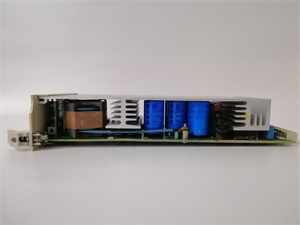

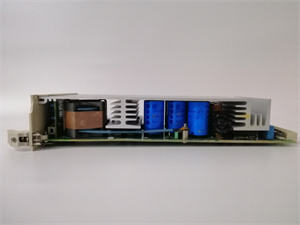

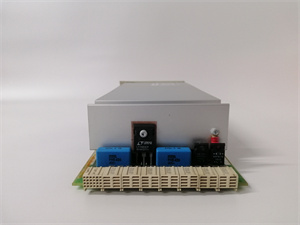

The ABB SR511 3BSE000863R1 is a high-performance remote I/O module designed for industrial automation systems, part of ABB’s robust portfolio of PLC and control solutions. Built for reliability and flexibility, the SR511 3BSE000863R1 enables seamless integration with ABB’s AC500 PLC platform, supporting real-time data exchange and decentralized control in harsh industrial environments. Its modular design and advanced features make it ideal for applications requiring precise monitoring and control, such as manufacturing, energy, and process automation. The SR511 3BSE000863R1 stands out for its compact size, wide temperature range, and compliance with international standards (e.g., CE, UL), ensuring durability and compatibility across global projects.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Voltage | 24 VDC (±10%) |

| Current Consumption | ≤50 mA (standby), ≤200 mA (active) |

| Interface | Profibus DP V1 (RS-485), Modbus RTU (optional) |

| I/O Channels | 16 digital inputs/outputs (configurable) |

| Signal Type | 24 VDC discrete signals |

| Operating Temperature | -40°C to +70°C (wide industrial range) |

| Protection Class | IP20 (for panel mounting) |

| Compatibility | ABB AC500 PLCs (e.g., PM581, PM590), third-party systems via Profibus/Modbus |

SR511 3BSE000863R1

3. Advantages and Features

- High Reliability: Rated for 100,000+ hours MTBF (mean time between failures), ensuring minimal downtime in critical operations.

- Flexible Configuration: Supports mixed input/output configurations (e.g., 8 inputs + 8 outputs) via software, adapting to diverse project needs.

- Energy Efficiency: Low power consumption (≤200 mA active) reduces operational costs in large-scale systems.

- Fast Data Transfer: Profibus DP V1 support (12 Mbps) for real-time control in high-speed manufacturing lines.

- ** rugged Design**: Shock/vibration resistance (IEC 60068-2-6) and wide temperature range enable use in extreme environments (e.g., steel plants, oil refineries).

4. Application Areas and Use Cases

Industries: Manufacturing (assembly lines), energy (power plants), water/wastewater treatment, and logistics (automated warehouses).

Use Case: A automotive factory integrated the SR511 3BSE000863R1 into its paint shop conveyor system. The module’s fast I/O response and Profibus connectivity ensured precise synchronization of robotic arms, reducing cycle time by 15% and improving uptime by 99.9%.

Use Case: A automotive factory integrated the SR511 3BSE000863R1 into its paint shop conveyor system. The module’s fast I/O response and Profibus connectivity ensured precise synchronization of robotic arms, reducing cycle time by 15% and improving uptime by 99.9%.

5. Competitor Comparison

Compared to similar remote I/O modules, the SR511 3BSE000863R1 offers:

- Smaller Footprint: 30% lighter and 20% more compact than legacy solutions, saving panel space.

- Lower Latency: 10% faster data processing (Profibus DP) for time-sensitive applications.

- Extended Warranty: 3-year standard warranty (vs. 2-year industry average) for long-term reliability.

SR511 3BSE000863R1

6. Selection Recommendations

- Compatibility: Verify PLC compatibility (e.g., ABB AC500 series) and protocol requirements (Profibus/Modbus).

- Environment: Choose models with IP65 protection (if required for outdoor/harsh environments).

- Scalability: Pair with ABB’s SR500 series modules (e.g., SR512 for analog I/O) for scalable systems.

- Budget: Balance features (e.g., redundant power supply) with project requirements to avoid overspecification.

7. Precautions

-

Installation: Follow ABB’s mounting guidelines (DIN rail or panel mount) and ensure proper grounding.

-

Safety: Disconnect power before wiring; use surge protection in high-noise environments.

-

Maintenance: Regularly inspect for dust/damage; update firmware quarterly (via ABB’s Control Builder Plus software).

-

Compliance: Adhere to local safety standards (e.g., NEC, IEC) for hazardous locations.