Description

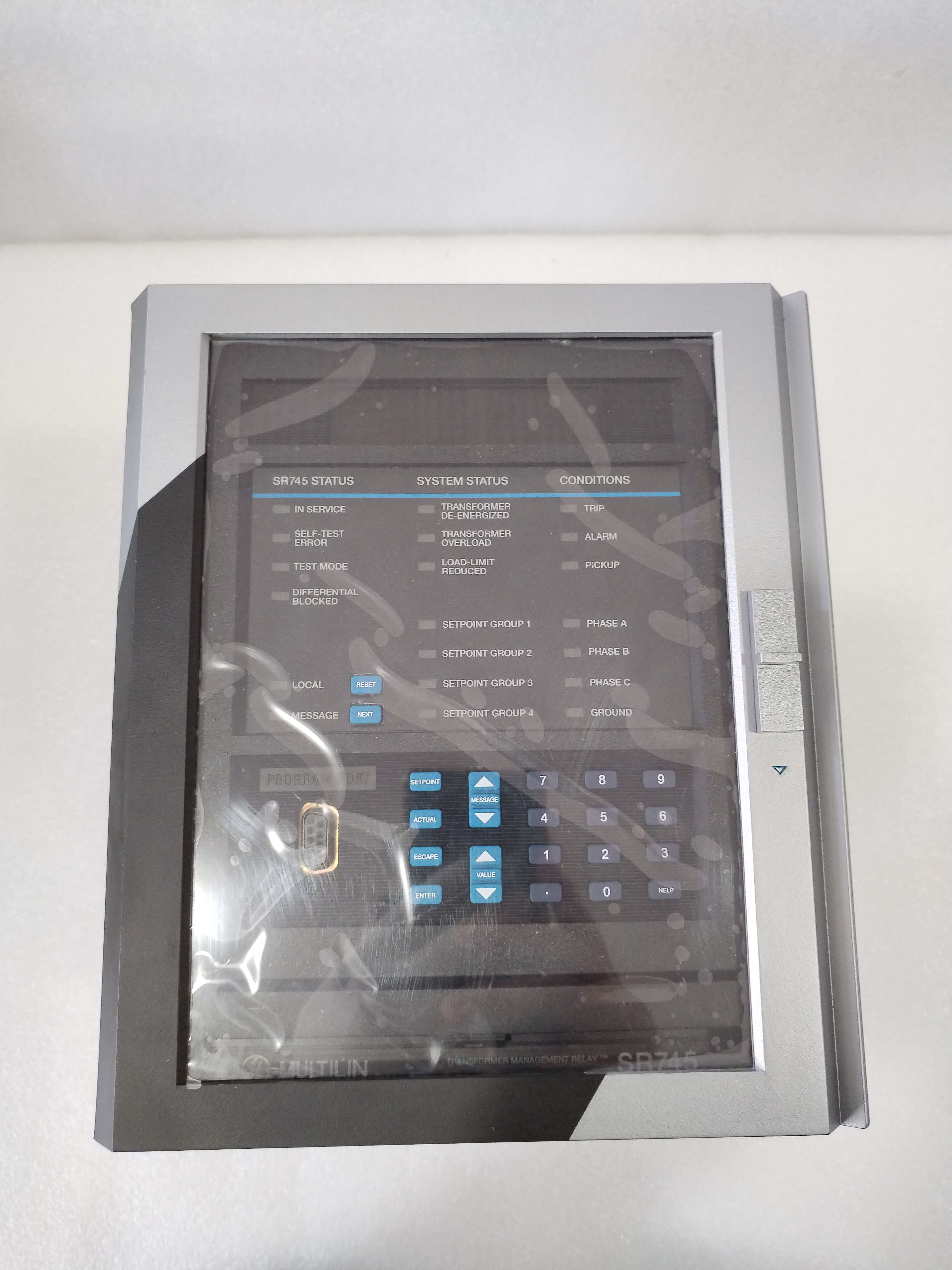

1. Product Description

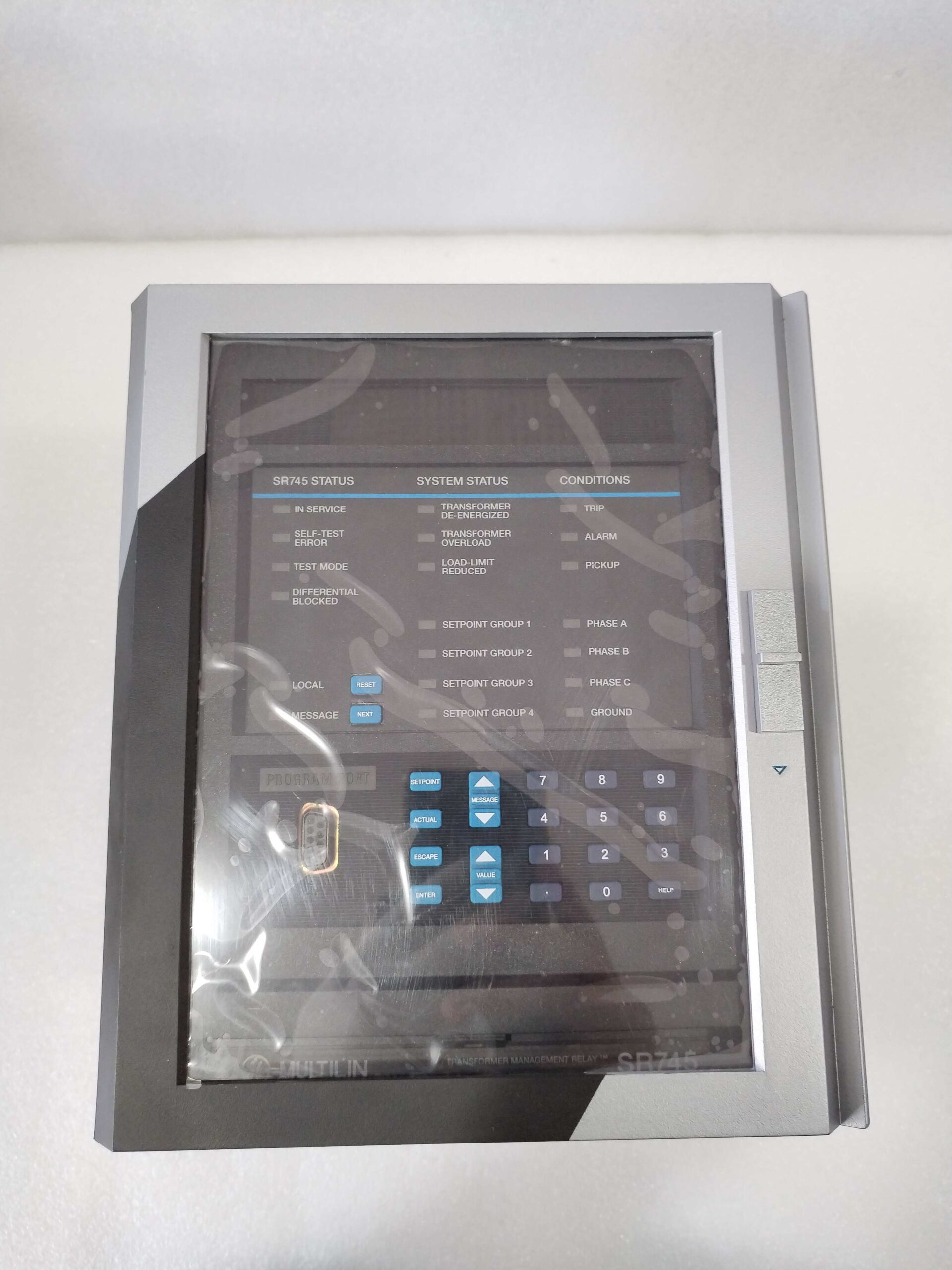

The GE SR745 – W2 – P5 – G5 – HI is a high – performance programmable logic controller (PLC) module from General Electric. It is designed to play a crucial role in industrial automation and control systems. This module is engineered to handle complex control tasks, providing reliable and efficient operation in a wide range of industrial environments.

The SR745 – W2 – P5 – G5 – HI is capable of processing a large number of input and output signals, enabling it to interface with various sensors, actuators, and other industrial devices. It supports multiple communication protocols, which allows seamless integration with other components in an automation system, such as human – machine interfaces (HMIs), supervisory control and data acquisition (SCADA) systems, and other PLCs. This module is ideal for applications that require high – speed data processing, precise control, and real – time monitoring.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Power Supply | 24V DC (±10%) |

| Input Voltage Range | 0 – 24V DC for digital inputs |

| Output Current Capacity | Up to 2A per output point for digital outputs |

| Communication Interfaces | Ethernet (10/100 Mbps), RS – 485, Profibus DP |

| Program Memory | 128 KB |

| Data Memory | 64 KB |

| Operating Temperature | – 20°C to 60°C |

| Humidity | 5% – 95% non – condensing |

| Dimensions | 120mm x 100mm x 60mm (W x H x D) |

| Weight | 0.5 kg |

| Compatibility | Compatible with other GE PLC series and related automation products |

SR745-W2-P5-G5-HI

3. Advantages and Features

- High – Speed Processing: The module features a powerful processor that can execute complex control algorithms at high speeds. It can achieve a program scan time of less than 1 ms per 1000 instructions, ensuring real – time response in industrial processes.

- Versatile Communication: With support for multiple communication protocols, it can easily connect to different types of industrial networks. For example, in a large – scale manufacturing plant, it can communicate with multiple workstations and other control devices via Ethernet, facilitating efficient data exchange and coordinated operation.

- Reliability: Built with high – quality components, the SR745 – W2 – P5 – G5 – HI has a high mean time between failures (MTBF) of over 100,000 hours. This makes it suitable for continuous operation in harsh industrial environments, such as in chemical plants or steel mills.

- Easy Programming: It supports standard programming languages like ladder logic, function block diagram, and structured text. This allows engineers with different programming backgrounds to easily develop and modify control programs.

4. Application Areas and Application Cases

- Application Areas:

- Manufacturing: It can be used in assembly lines, robotic control systems, and packaging machines to control the movement of equipment, monitor production parameters, and ensure product quality.

- Energy: In power plants, it can be applied to control the operation of turbines, generators, and other power – generation equipment. It can also be used in renewable energy systems, such as wind farms and solar power plants, for power management and control.

- Water Treatment: For controlling water pumps, valves, and other equipment in water treatment plants, ensuring the proper treatment and distribution of water.

- Application Case:

- In an automotive manufacturing plant, the SR745 – W2 – P5 – G5 – HI was used to control a robotic welding line. The module’s high – speed processing and precise control capabilities enabled the robots to perform welding operations with high accuracy, reducing the defect rate by 15% and increasing the production efficiency by 20%.

5. Competitor Comparison

Compared to similar products in the market, the SR745 – W2 – P5 – G5 – HI has several advantages. Firstly, its high – speed processing capabilities are superior to many competitors, which allows for faster control responses and more efficient operation. Secondly, its wide range of supported communication protocols provides greater flexibility in system integration, while some competitors may only support a limited number of protocols. Additionally, GE’s reputation for reliability and after – sales support gives users more confidence in choosing this module.

SR745-W2-P5-G5-HI

6. Selection Recommendations

- Compatibility: Ensure that the module is compatible with your existing automation system, including other PLCs, HMIs, and communication networks. Check the communication protocols and interface requirements to avoid integration issues.

- Performance Requirements: Evaluate your control tasks and determine the required processing speed, memory capacity, and input/output points. If your application involves complex control algorithms or high – speed data processing, the SR745 – W2 – P5 – G5 – HI‘s high – performance features may be necessary.

- Budget: Consider your budget constraints. While the SR745 – W2 – P5 – G5 – HI offers high – end features, there may be more cost – effective options for less demanding applications. However, keep in mind that the long – term reliability and performance benefits may justify the initial investment.

- Environmental Conditions: If your plant operates in extreme environmental conditions, such as high temperatures, high humidity, or high levels of dust, ensure that the module’s operating temperature and humidity ratings are suitable.

7. Precautions

- Installation: Follow the manufacturer’s installation instructions carefully. Ensure proper grounding and cable routing to prevent electrical interference.

- Configuration: When configuring the module, double – check all settings to avoid errors. Use the recommended programming software and follow the standard configuration procedures.

- Maintenance: Regularly perform maintenance checks, including firmware updates. The diagnostic functions of the module can help in identifying potential issues early. However, if any fault is detected, consult a qualified technician for repair.

- Safety: Always follow safety procedures when working with the module. Disconnect the power supply before performing any maintenance or installation tasks.