Description

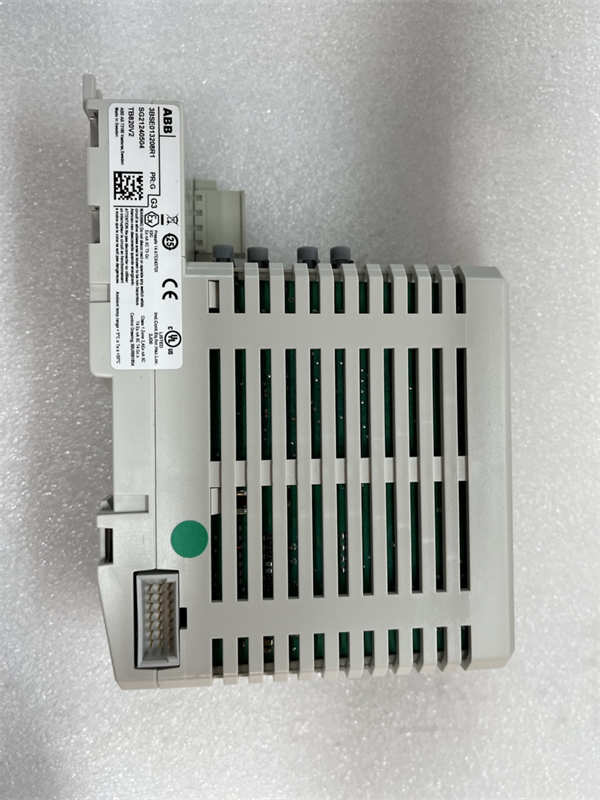

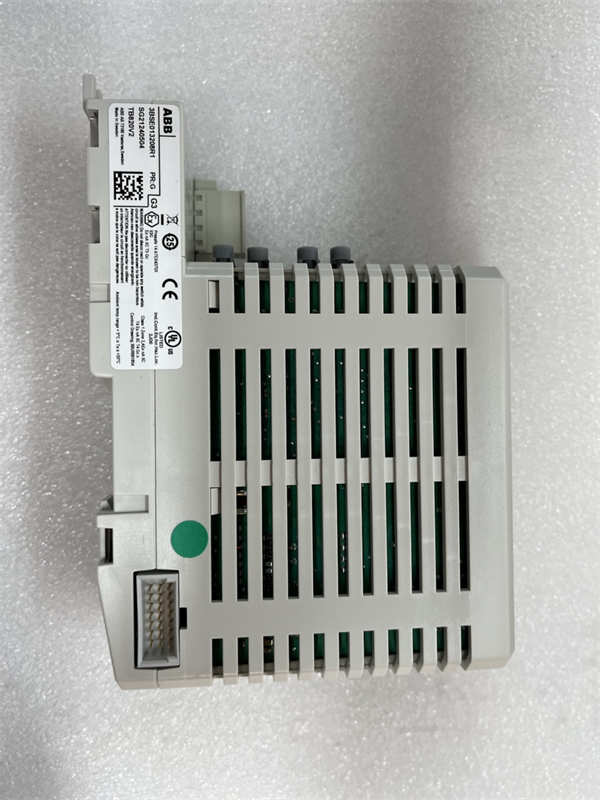

ABB TB820V2 3BSE013208R1: Fiber Optic Communication Module for Industrial Distributed I/O Systems

The ABB TB820V2 3BSE013208R1 is a high-performance fiber optic communication module designed for ABB’s S800 I/O system, enabling reliable and high-speed data transmission in distributed industrial automation setups. As a core component of the Module Bus architecture, the TB820V2 bridges local I/O modules with remote clusters via fiber optic links, ensuring immunity to electromagnetic interference (EMI) and supporting long-distance communication (up to 20 km). Ideal for harsh environments, this module is widely used in manufacturing, energy, water treatment, and marine industries.

1. Product Description

The TB820V2 serves as a fiber optic gateway for ABB’s S800 I/O system, supporting both electrical (local) and fiber optic (remote) Module Bus connections. It enables seamless integration of up to 12 local I/O modules and expands the system to 7 remote clusters via fiber optic links. Key features include:

- Dual Interface Support: Electrical (local) and fiber optic (remote) ports for hybrid network configurations.

- EMI Immunity: Fiber optic links eliminate signal degradation in high-noise environments.

- Scalability: Configurable cluster addressing (1–7) for flexible system expansion.

- Redundancy Ready: Supports Module Bus redundancy (with system configuration) for enhanced reliability.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Type | Fiber Optic Module Bus Modem |

| Voltage | 24V DC (±10%) |

| Current Consumption | 100 mA (typical) |

| Interfaces | 2x Fiber Optic Ports (Module Bus) + 1x Electrical Bus (local I/O) |

| Max. Local I/O Modules | 12 (via electrical bus) |

| Max. Remote Clusters | 7 (via fiber optic links) |

| Communication Range | Fiber: Up to 20 km (multimode/single-mode) |

| Operating Temperature | 0°C to +55°C (vertical mounting: up to 40°C) |

| Mounting | DIN Rail (IP20 protection) |

| Certifications | CE, UL, ATEX (Zone 2), Marine (ABS, BV) |

TB820V2

3. Advantages and Features

- Reliable Long-Distance Communication: Fiber optic links reduce signal attenuation and EMI, ensuring stable data transfer in complex industrial settings.

- Flexible Clustering: Configurable cluster addressing (1–7) allows scalable deployment across large facilities.

- Redundancy Architecture: Supports dual Module Bus configuration (electrical/fiber) for 99.99% uptime in critical applications.

- Compact Design: 58 mm width saves 30% panel space compared to legacy solutions.

- Case Study: A German automotive plant reduced downtime by 25% using the TB820V2 to connect 50+ remote I/O clusters in a high-EMI welding shop. Fiber optic links eliminated signal errors, improving system reliability.

4. Application Areas and Cases

- Industries: Manufacturing, energy (power plants, renewables), water treatment, marine/shipbuilding.

- Scenarios: Distributed I/O systems, remote machine monitoring, and substation automation.

- Application Case: A Norwegian offshore wind farm deployed TB820V2 modules to connect 100+ sensors across 15 km of cabling. Fiber optic redundancy and EMI immunity ensured 99.8% data integrity in harsh offshore conditions.

5. Competitor Comparison

Compared to similar communication modules:

- Superior EMI Protection: Fiber optic links (vs. copper-based solutions in alternatives).

- Longer Communication Range: 20 km fiber support (vs. 1 km typical for electrical buses).

- Higher Cluster Density: 7 remote clusters (vs. 4–5 for most 竞品).

- Native Redundancy: Built-in support for dual Module Bus (no external hardware required).

TB820V2

6. Selection Recommendations

- System Compatibility: Ensure integration with ABB S800 I/O, AC500, or 800xA systems.

- Environment: Opt for fiber optic links in high-EMI, long-distance, or corrosive environments.

- Scalability: Choose the TB820V2 for systems requiring 7+ remote clusters (vs. electrical-only modules).

- Budget: Balance fiber optic benefits (reliability, distance) with upfront costs (fiber cabling investment).

7. Precautions

- Installation:

- Use ST/LC fiber connectors (single-mode for >2 km, multimode for short distances).

- Ensure proper grounding for the electrical bus; avoid bending fiber cables (minimum bend radius: 30 mm).

- Maintenance:

- Clean fiber connectors quarterly with lint-free wipes (avoid physical damage).

- Monitor cluster status via ABB’s Control Builder M (verify LED indicators: green=active, red=fault).

- Redundancy: Enable dual Module Bus (electrical + fiber) for SIL 2/3 applications (follow IEC 61508 guidelines).