Description

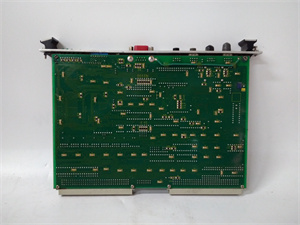

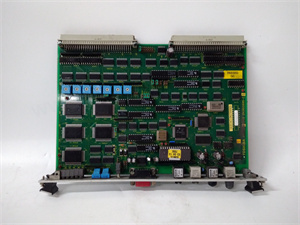

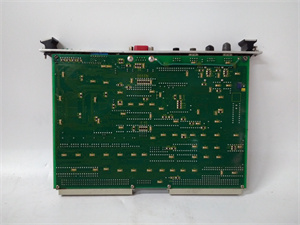

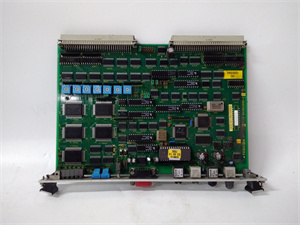

Product Description: TOSHIBA HC422B N-300 Intelligent Ethernet Connection Module

The TOSHIBA HC422B N-300 is a high-performance intelligent Ethernet connection module designed for industrial automation systems, enabling seamless integration of field devices with control networks. Built on industrial Ethernet and Profibus-DP architecture, the HC422B N-300 supports HART protocol for unified management of intelligent field instruments, ensuring reliable data transmission between PLCs, DCS systems, and enterprise resource planning (ERP) platforms. With advanced control algorithms and low-power design, it optimizes production efficiency and reduces lifecycle costs in industries such as manufacturing, energy, and chemical processing.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | HC422B N-300 |

| Brand | TOSHIBA |

| Module Type | Industrial Ethernet/Profibus-DP Gateway |

| Protocol Support | HART, Modbus, Profibus-DP, Ethernet/IP |

| Voltage Range | 12–24V DC (wide-range power supply) |

| Operating Temperature | -40°C to +70°C (industrial-grade durability) |

| Interfaces | RJ45 (Ethernet), Profibus-DP (9-pin D-sub) |

| Power Consumption | <5W (low-power mode supported) |

| Certifications | CE, UL (industrial safety standards) |

| Compatibility | TOSHIBA PLC systems, third-party DCS/SCADA (e.g., ABB, Siemens) |

| Dimensions | Compact 190 × 110 × 60 mm (rack-mounted design) |

TOSHIBA HC422B N-300

Advantages and Features

-

Multi-Protocol Integration:

- Supports HART, Profibus-DP, and Ethernet/IP for unified management of smart sensors, actuators, and control systems.

- Enables real-time data exchange between field devices and enterprise-level platforms (MES/ERP).

-

Rugged Design:

- Industrial-grade temperature range (-40°C to +70°C) and EMI/EMC protection for harsh environments.

- Low-power mode (<5W) reduces energy consumption in remote or battery-powered applications.

-

Advanced Control Algorithms:

- Embedded thermal and chemical process control algorithms for optimized production efficiency.

- Seamless integration with TOSHIBA’s PLC systems and third-party automation platforms.

-

Scalability:

- Supports up to 64 field devices per module, reducing cabling complexity in large-scale installations.

Application Areas and Use Cases

Industry Applications:

- Manufacturing (smart factories, predictive maintenance).

- Energy (power plants, renewable energy monitoring).

- Chemical (process control, safety instrumented systems).

- Oil & Gas (remote terminal units, pipeline monitoring).

Case Study:

A chemical plant in Germany integrated the TOSHIBA HC422B N-300 to connect 50 HART-enabled sensors and valves across three production lines. The module’s multi-protocol support and real-time data analytics reduced downtime by 25% and improved process yield by 12%. Its low-power design also cut energy costs by 18% in remote monitoring stations.

TOSHIBA HC422B N-300

Competitive Comparison

Compared to similar industrial communication modules:

- Broader Protocol Support: Integrates HART, Profibus-DP, and Ethernet/IP (vs. limited single-protocol support in 竞品).

- Higher Temperature Range: Operates at -40°C (vs. standard -20°C in comparable modules), suitable for extreme climates.

- Lower Power Consumption: <5W (vs. 6–8W in 竞品), ideal for battery-powered or energy-sensitive setups.

- Scalability: Supports 64 devices (vs. 32–48 devices in 竞品), reducing module count in large systems.

Selection Recommendations

- System Requirements: Choose the HC422B N-300 for systems needing multi-protocol integration (HART + Profibus-DP + Ethernet).

- Environment: Opt for this module in extreme temperatures (-40°C to +70°C) or high-vibration settings.

- Compatibility: Ensure alignment with TOSHIBA PLCs or third-party systems (e.g., Emerson DeltaV, Honeywell Experion).

- Cost-Efficiency: Balance upfront costs with long-term savings (e.g., reduced maintenance and energy use).

Precautions

-

Installation:

- Follow ESD protection guidelines (use grounded tools and anti-static mats).

- Verify voltage compatibility (12–24V DC) before powering the module.

-

Operation:

- Avoid exceeding the maximum temperature (+70°C) or voltage (24V DC).

- Use shielded cables for Ethernet/Profibus-DP connections to minimize interference.

-

Maintenance:

- Regularly update firmware for protocol patches and security enhancements.

- Inspect connectors for corrosion or loose connections every 6 months.