Description

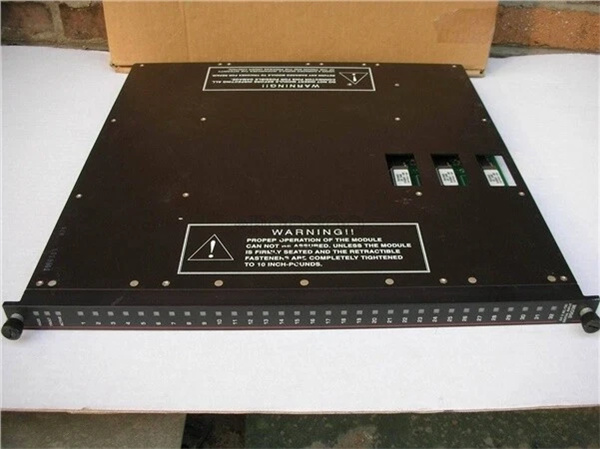

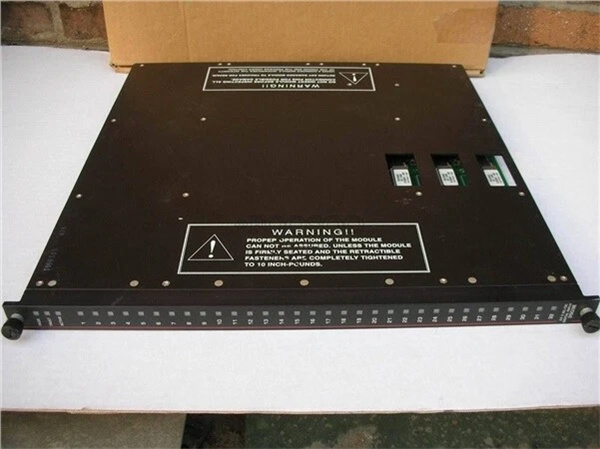

1. Product Description

The TRICONEX 3502E is a highly reliable digital input module designed specifically for safety-critical industrial applications within the TRICONEX safety instrumented systems (SIS). It plays a crucial role in receiving and processing digital signals from a variety of field sensors, ensuring the integrity and safety of industrial processes.

The core function of the TRICONEX 3502E is to interface with different types of sensors such as limit switches, proximity switches, and pressure sensors, converting their binary states into digital data that can be used by the control system. With 32 digital input channels grouped into 8 commoned channels, it can monitor multiple signals simultaneously, making it suitable for complex industrial setups. The module operates at a voltage of 48V AC/DC, providing stable power for sensor input.

One of the significant advantages of the TRICONEX 3502E is its advanced diagnostic capabilities. It continuously monitors its own operation and can detect faults in the input channels or the module itself, allowing for quick identification and resolution of issues. Additionally, it features a fail-safe design, ensuring that in the event of a fault, it will enter a safe state to prevent potential hazards. The module also has relevant certifications for use in hazardous areas, enhancing its safety and reliability in such environments.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Digital Input Module |

| Operating Voltage | 48V AC/DC |

| Input Channels | 32 channels, grouped into 8 commoned channels |

| Input Signal Types | Suitable for signals from limit switches, proximity switches, pressure sensors etc. |

| Certifications | CE and certifications for hazardous areas |

| Compatibility | Compatible with TRICONEX safety instrumented systems and various field sensors |

| Operating Temperature | 0°C to 50°C |

| Relative Humidity | Up to 90% non-condensing |

| Isolation | Yes, provides isolation for input channels |

TRICONEX 3502E

3. Advantages and Characteristics

- High Reliability: Thanks to its triple modular redundancy (TMR) architecture, the TRICONEX 3502E can maintain operation even if one of its internal components fails. In a large chemical plant, during a long-term operation, when one channel was affected by electrical interference, the TMR system allowed the module to continue functioning without interruption, ensuring the continuous operation of the chemical production process. The module has a mean time between failures (MTBF) that is significantly high, reducing the risk of unexpected system downtime.

- Fail-Safe Design: In case of a fault, the TRICONEX 3502E automatically enters a safe state. For example, in an oil refinery’s emergency shutdown system, if the module detects an abnormal condition in the input signals or a fault within itself, it will trigger the necessary safety actions to prevent potential accidents, safeguarding the facility and personnel.

- Comprehensive Diagnostic Function: The built-in diagnostic features can quickly identify faults, reducing troubleshooting time. In a power generation plant, when a sensor connection issue occurred, the module’s diagnostic system immediately indicated the problem, allowing maintenance staff to locate and fix the issue within a short time, minimizing the impact on power generation.

- Hazardous Area Certification: With certifications for use in hazardous areas, the TRICONEX 3502E can be safely deployed in environments with explosive or flammable substances, such as offshore oil platforms or chemical storage facilities.

4. Application Areas and Application Cases

-

Industry Applications:

- Oil and Gas: Used in offshore platforms and onshore refineries for monitoring the status of valves, pumps, and safety devices. It can detect the open/closed state of emergency shutdown valves and other critical equipment, ensuring the safety of the production process.

- Chemical Processing: In chemical plants, the TRICONEX 3502E is applied to monitor safety interlocks, such as the status of pressure relief valves, temperature sensors in reactors, and flow switches. It helps in preventing hazardous situations and ensuring the smooth operation of chemical reactions.

- Power Generation: Employed in power plants for turbine control systems, generator protection, and substation automation. It can monitor the position of circuit breakers, the status of protective relays, and other important parameters to ensure the stable operation of the power grid.

- Manufacturing: Used in automated manufacturing lines to monitor the operation status of robotic arms, conveyor belts, and other production equipment. It enables real-time control and quality management, improving production efficiency and product quality.

-

Case Study: In a large petrochemical plant, the TRICONEX 3502E was installed in the safety instrumented system to monitor the signals from over 20 different types of sensors. One day, during normal operation, the module detected a fault in the signal from a pressure sensor in a high-pressure pipeline. The fail-safe design of the TRICONEX 3502E immediately triggered an alarm and sent a signal to the control system, which then initiated the emergency shutdown sequence for that part of the pipeline. The comprehensive diagnostic function also helped the maintenance team quickly identify the faulty sensor and replace it, preventing a potential pipeline rupture and ensuring the safety of the entire plant.

5. Competitive Comparison

Compared to some similar digital input modules in the market, the TRICONEX 3502E stands out due to its combination of high reliability, advanced diagnostic capabilities, and fail-safe design. Many competing products may lack the comprehensive diagnostic features or the ability to enter a safe state in case of a fault. The TRICONEX 3502E‘s TMR architecture provides a higher level of redundancy, making it more reliable in critical applications. Additionally, its certifications for hazardous areas are more comprehensive, allowing it to be used in a wider range of challenging industrial environments.

TRICONEX 3502E

6. Selection Recommendations

- System Compatibility: Ensure that the TRICONEX 3502E is compatible with your existing TRICONEX control system, including the backplane, software, and other connected modules. Check the communication protocols and data interfaces to ensure seamless integration.

- Sensor Compatibility: Consider the types of sensors you will be using with the module. Make sure the TRICONEX 3502E can handle the input signals from your sensors, such as voltage levels, signal types, and frequency ranges.

- Installation Environment: Take into account the environmental conditions where the module will be installed. If it is in a harsh environment with high temperatures, humidity, or electromagnetic interference, ensure that the TRICONEX 3502E can operate reliably under those conditions. Also, consider the available space for installation and the ease of wiring.

- Budget Considerations: While the TRICONEX 3502E offers high performance and reliability, it is important to consider your budget. Compare the cost of the module with the benefits it provides, such as reduced downtime, enhanced safety, and improved productivity. Consider the long-term cost savings associated with its reliability and ease of maintenance.

7. Precautions

- Installation: When installing the TRICONEX 3502E, follow the manufacturer’s installation instructions carefully. Ensure proper grounding to prevent electrical interference and ensure the safety of the module and connected equipment. Use appropriate cables and connectors to avoid signal loss or electrical hazards.

- Wiring: Double-check all wiring connections to ensure they are correct and secure. Incorrect wiring can lead to inaccurate input readings or damage to the module. Use shielded cables if necessary to protect against electromagnetic interference.

- Maintenance: Regularly check the module’s diagnostic status to monitor for any potential faults or issues. Clean the module and its connectors periodically to prevent dust and dirt from affecting its performance. Update the module’s firmware as recommended by the manufacturer to ensure the latest features and security patches.

- Safety: When working with the TRICONEX 3502E in hazardous areas, follow all safety regulations and procedures. Use appropriate personal protective equipment (PPE) and ensure that all installation and maintenance work is carried out by trained personnel.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.