Description

1. Product Description

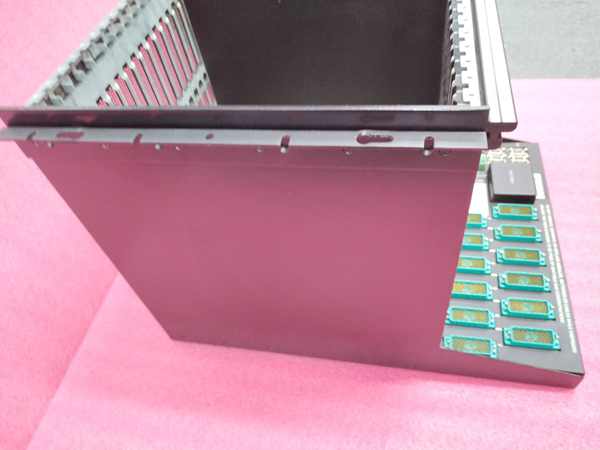

The TRICONEX 8110 is a high-density and highly reliable main chassis that serves as the backbone of safety-critical industrial control systems. As a crucial component of safety instrumented systems (SIS), the TRICONEX 8110 plays a vital role in monitoring and protecting industrial equipment and processes.

The core function of the TRICONEX 8110 is to provide a stable and secure platform for housing and integrating up to 32 TRICONEX I/O modules. It features a four-position key switch that controls all the chassis in the system, and its settings can be easily read by TRICON controllers, Tristation 1131 software, and control programs. This allows for precise management and control of the entire system. The chassis is designed to ensure seamless communication and data transfer between the I/O modules and the control system, enabling real-time monitoring and control of various industrial parameters.

One of the significant advantages of the TRICONEX 8110 is its triple modular redundancy (TMR) architecture. This design ensures that the system can continue to operate without interruption even in the event of component failures or transient faults. Additionally, the chassis comes with two redundant power supplies, providing enhanced reliability and ensuring continuous operation during power fluctuations or outages. The hot-swappable feature of all I/O modules allows for easy replacement and maintenance without the need to shut down the entire system, minimizing downtime and improving productivity.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Main Chassis for SIS |

| Dimensions | 18.31″ (46.5 cm) x 22.75″ (57.8 cm) x 13.12″ (33.3 cm) |

| Weight | Approximately 110 lbs (50 kg) |

| Power Requirements | 10A at 120V DC |

| Operating Temperature | -40°C to +70°C (-40°F to +158°F) |

| Humidity | 0% to 95% non-condensing |

| Vibration Resistance | 0.03 g rms overall, 5 Hz to 500 Hz |

| Shock Resistance | 5 g half-sine, 20 msec duration |

| EMC Compliance | Meets IEC 61000 – 4 – 2, IEC 61000 – 4 – 3, and IEC 61000 – 4 – 6 standards |

| Expansion Ports | Six RS – 485 I/O expansion bus ports, two sets of ports for channel A, B and C |

| Redundancy | Triple Modular Redundancy (TMR), two redundant power supplies |

| SIL Certification | SIL 3 (Safety Integrity Level 3) |

TRICONEX 8110

3. Advantages and Characteristics

- High Reliability: Thanks to its TMR architecture, the TRICONEX 8110 can maintain system operation even when one of the three modules fails. In a large chemical plant, during a long-term operation, when one of the internal components of the chassis malfunctioned due to electrical interference, the TMR system quickly detected and isolated the fault, allowing the other two modules to continue functioning without any impact on the overall control system. The redundant power supplies also contribute to its high reliability, ensuring that the system remains operational even in the face of power issues.

- Hot-Swappable Modules: The ability to hot-swap I/O modules is a significant advantage. In a manufacturing facility, when a faulty I/O module needed to be replaced, the maintenance team was able to do so without shutting down the production line. This feature not only saves time but also reduces the risk of production losses due to system downtime.

- High Density and Scalability: With the capacity to house up to 32 I/O modules, the TRICONEX 8110 offers high density, allowing for a more compact and efficient system design. In a growing industrial plant, as the need for additional I/O capabilities increased, new modules could be easily added to the chassis, expanding the system’s functionality without major overhauls.

- SIL 3 Certification: The SIL 3 certification attests to the high safety integrity of the TRICONEX 8110. This makes it suitable for use in applications where safety is of utmost importance, such as in the oil and gas industry, where it can be used to control critical processes and prevent accidents.

4. Application Areas and Application Cases

-

Industry Applications:

- Oil and Gas: In offshore oil platforms and onshore refineries, the TRICONEX 8110 is used to monitor and control various processes, including wellhead operations, pipeline flow, and safety systems. It ensures the safe and efficient production and transportation of oil and gas by continuously monitoring parameters such as pressure, temperature, and flow rate.

- Chemical Processing: In chemical plants, the chassis is employed to manage chemical reactions, control the flow of chemicals, and monitor safety interlocks. It helps in preventing hazardous situations and ensuring the quality of chemical products by providing precise control and monitoring.

- Power Generation: For power plants, the TRICONEX 8110 is used in turbine control systems, generator protection, and grid stability management. It plays a crucial role in ensuring the stable generation and distribution of electricity, safeguarding the power grid from disruptions.

- Manufacturing: In manufacturing industries, it is used to control automated production lines, robotic arms, and other manufacturing equipment. It enables real-time monitoring and control of the production process, improving productivity and product quality.

-

Case Study: In an offshore oil platform, the TRICONEX 8110 was installed as the main chassis for the safety instrumented system. During a severe storm, the platform experienced power fluctuations and electrical interference. However, due to the redundant power supplies and TMR architecture of the TRICONEX 8110, the system continued to operate without any interruptions. The hot-swappable I/O modules also allowed for quick replacement of a module that was affected by the electrical interference, ensuring that the platform’s safety systems remained fully functional and protecting the lives of the workers and the integrity of the equipment.

5. Competitive Comparison

Compared to other main chassis products in the market, the TRICONEX 8110 stands out due to its combination of high density, high reliability, and ease of maintenance. Many competing products may not offer the same level of redundancy or the ability to hot-swap modules, which can lead to longer downtime in case of component failures. The TRICONEX 8110‘s SIL 3 certification also gives it an edge over products with lower safety integrity levels, making it a more suitable choice for safety-critical applications. Additionally, its compatibility with a wide range of TRICONEX I/O modules and control systems provides greater flexibility and scalability compared to some other chassis that may have limited compatibility.

TRICONEX 8110

6. Selection Recommendations

- System Compatibility: When selecting the TRICONEX 8110, it is essential to ensure that it is compatible with your existing control system, including the software, controllers, and other components. Check the communication protocols and interfaces to ensure seamless integration.

- Installation Environment: Consider the environmental conditions where the chassis will be installed. The TRICONEX 8110 has a wide operating temperature range, but it is still important to ensure that the installation site meets the temperature and humidity requirements. Also, consider factors such as vibration and shock resistance if the installation environment is prone to such conditions.

- I/O Requirements: Determine your current and future I/O requirements. The TRICONEX 8110 can house up to 32 I/O modules, so make sure it can accommodate your needs. Consider the types of I/O modules you will be using and their compatibility with the chassis.

- Budget Considerations: While the TRICONEX 8110 offers high performance and reliability, it is important to consider your budget. Compare the cost of the chassis with the benefits it provides, such as reduced downtime, enhanced safety, and scalability. Also, consider the long-term maintenance and operating costs associated with the product.

7. Precautions

- Installation: When installing the TRICONEX 8110, follow the manufacturer’s installation instructions carefully. Ensure that the installation location is stable and well-ventilated to prevent overheating. Use appropriate grounding and wiring to ensure electrical safety.

- Power Supply: Use a stable and reliable power source that meets the power requirements of the chassis. Avoid using power supplies with excessive voltage fluctuations or noise, as this can affect the performance and lifespan of the chassis. Consider using a UPS (Uninterruptible Power Supply) to provide backup power in case of outages.

- Maintenance: Regularly check the status of the chassis and the I/O modules using the diagnostic LEDs and software tools. Clean the chassis and the modules periodically to prevent dust and dirt from affecting their performance. Replace any faulty components immediately to ensure the continued operation of the system.

- Safety: When working with the TRICONEX 8110, follow all relevant safety regulations and procedures. Use appropriate personal protective equipment (PPE) when handling the chassis and the modules. Ensure that all installation and maintenance work is carried out by trained personnel.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.