Description

1. Product Description

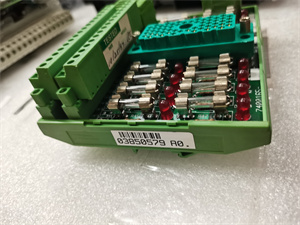

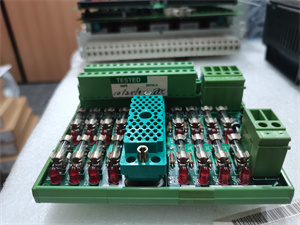

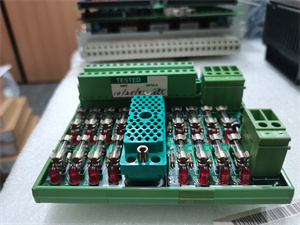

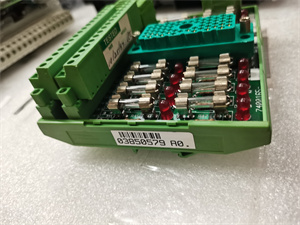

TRICONEX 9561-810 is a high-reliability analog input module designed for safety-critical industrial automation systems, delivering precise signal conditioning and fault-tolerant performance. As a key component of TRICONEX’s triple modular redundancy (TMR) platform, the 9561-810 is engineered to interface with analog sensors (e.g., transmitters, thermocouples, RTDs) in harsh environments such as oil and gas, chemical processing, and power generation. This module processes 4-20 mA, voltage, thermocouple, and RTD signals with exceptional accuracy, ensuring seamless integration into TRICONEX’s Tricon controller architecture. The TRICONEX 9561-810 prioritizes operational safety and data integrity, making it ideal for applications requiring SIL 3 compliance (IEC 61508) and robust resistance to electrical noise and interference.

2. Product Parameters

| Parameter | Details |

|---|---|

| Signal Types | 4-20 mA, 0-10 V, ±10 V, thermocouples (J, K, T, E, R, S, B, N), RTDs (2/3/4-wire) |

| Channels | 8 isolated channels |

| Input Range | 4-20 mA: 0-24 mA; Voltage: -15 V to +15 V; Thermocouples: Full range per type; RTDs: -200°C to +850°C |

| Resolution | 16-bit analog-to-digital conversion |

| Accuracy | ±0.05% of full scale (typ.) |

| Redundancy Support | TMR (Triple Modular Redundancy) |

| Operating Temperature | -40°C to +70°C |

| Certification | CE, FM, CSA, ATEX, IECEx (hazardous area approved) |

| Dimensions | 102 mm (W) x 178 mm (H) x 64 mm (D) |

TRICONEX 9561-810

3. Advantages and Features

The TRICONEX 9561-810 excels in critical applications due to its TMR architecture, which provides triple redundancy for all signal paths and uses a voting mechanism to eliminate single-point failures. Key advantages include:

- Multi-Signal Flexibility: Supports up to four signal types per module, reducing inventory complexity and installation costs.

- Galvanic Isolation: Each channel is isolated to prevent ground loops and voltage surges, ensuring stable signal transmission in noisy environments.

- Advanced Diagnostics: Built-in self-test (BIST) continuously monitors channel health, with fault detection latency <10 ms for proactive maintenance.

- Hot Swappable Design: Enables module replacement without system shutdown, minimizing downtime during maintenance.

4. Application Areas and Case Studies

The 9561-810 is widely used in industries requiring precise analog signal measurement, including:

- Oil & Gas: Pressure and temperature monitoring in wellheads, pipelines, and refineries.

- Chemical Processing: Level control in reactors, pH sensing in filtration systems, and flow rate monitoring.

- Power Generation: Steam turbine temperature profiling, boiler feedwater flow control, and generator load sensing.

Case Study: A European chemical plant upgraded its safety system with TRICONEX 9561-810 modules to monitor 50+ temperature and pressure points in a high-purity production line. The module’s 16-bit resolution and noise immunity reduced measurement errors by 92%, while its TMR design eliminated unplanned shutdowns caused by single-channel failures, resulting in a 30% increase in annual production uptime.

5. Competitor Comparison

Compared to standard analog input modules, the TRICONEX 9561-810 offers superior safety integrity (SIL 3 vs. typical SIL 2) and signal versatility (supporting RTD/thermocouple/voltage/current in a single module). Its TMR architecture achieves a mean time between failures (MTBF) of over 120,000 hours, significantly outperforming non-redundant alternatives. The module’s compact 8-channel design also optimizes space compared to competitors offering fewer channels per unit, reducing cabinet size and cabling complexity.

TRICONEX 9561-810

6. Selection Recommendations

When selecting the TRICONEX 9561-810, consider:

- Signal Type Mix: Evaluate whether your application requires a combination of current, voltage, thermocouple, or RTD signals to leverage the module’s multi-signal capability.

- Accuracy Requirements: Ensure the 16-bit resolution and ±0.05% accuracy meet your process control precision needs.

- Environmental Factors: Confirm the module’s operating temperature range (-40°C to +70°C) and vibration resistance align with your site conditions.

- Safety Compliance: Verify SIL 3 certification aligns with your industry’s safety standards (e.g., IEC 61511 for process safety).

7. Precautions

- Cabling Standards: Use shielded twisted-pair cables for analog signals and separate them from power cables to minimize EMI/RFI interference.

- Thermocouple/RTD Wiring: Follow manufacturer guidelines for polarity and lead-wire compensation to ensure accurate temperature measurements.

- ESD Protection: Ground all equipment and use anti-static wrist straps during installation to prevent damage to sensitive components.

- Firmware Updates: Regularly update firmware to address security patches and optimize compatibility with newer controller versions.

- Hazardous Area Installation: Install the module in certified explosion-proof enclosures and comply with ATEX/IECEx guidelines for Zone 0/1 environments.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.