Description

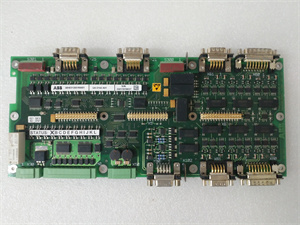

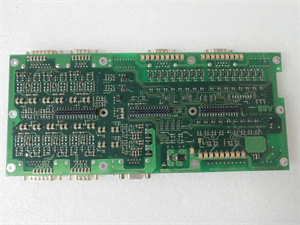

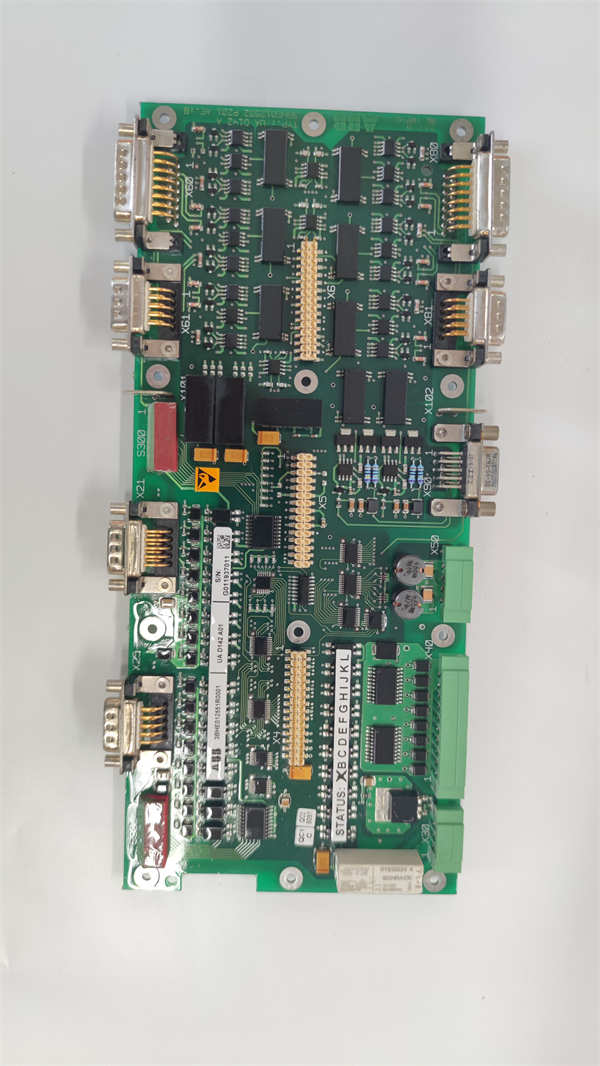

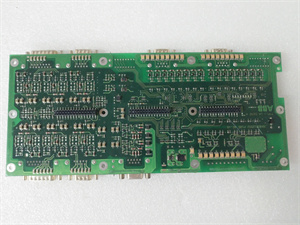

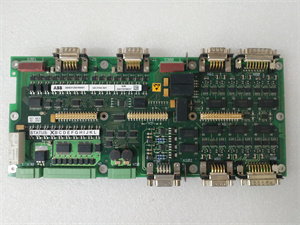

ABB UAD142A01 3BHE012551R0001 Analog Input Module

The UAD142A01 3BHE012551R0001 is a high-precision analog input module developed by ABB, designed to enable accurate signal acquisition from field devices in industrial automation systems. Engineered for reliability and versatility, the UAD142A01 3BHE012551R0001 converts analog signals from sensors (e.g., temperature, pressure, flow transmitters) into digital data for processing by PLCs, DCS systems, or control processors. As part of ABB’s S800 I/O family, this module is trusted in critical applications requiring precise measurement and robust environmental resilience.

1. Product Description

The UAD142A01 3BHE012551R0001 serves as a vital interface between analog field devices and control systems, ensuring seamless data integration for real-time monitoring and control. Key functions include:

- High-Accuracy Signal Conversion: Processes up to 8 analog input channels with a resolution of 16 bits, ensuring measurement accuracy within ±0.1% of full scale for signals like 4–20mA, 0–10V, or thermocouples.

- Wide Signal Support: Natively supports multiple analog signal types, eliminating the need for external signal conditioners and reducing hardware complexity.

- Rugged Design: Withstands harsh industrial environments, operating reliably at temperatures from -40°C to +70°C and resisting electromagnetic interference (EMI) and vibrations.

- Hot-Swap Capability: Allows module replacement without powering down the system, minimizing downtime during maintenance or upgrades.

The UAD142A01 3BHE012551R0001 simplifies system configuration with plug-and-play connectivity and built-in diagnostics, making it an ideal choice for both new installations and retrofitting legacy automation setups.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Brand | ABB |

| Model | UAD142A01 3BHE012551R0001 |

| Module Type | Analog Input Module (8-channel) |

| Signal Types | 4–20mA, 0–10V, ±10V, thermocouples (J, K, T, E, R, S, B), RTDs (Pt100, Pt1000) |

| Resolution | 16 bits |

| Accuracy | ±0.1% of full scale (25°C) |

| Voltage Supply | 24V DC ±10% (powered via I/O bus) |

| Power Consumption | ≤8W (active), ≤3W (standby) |

| Operating Temperature | -40°C to +70°C (non-condensing humidity: 5%–95%) |

| Storage Temperature | -40°C to +85°C |

| Communication Interface | Serial communication with control processor (via S800 I/O bus) |

| Dimensions (W×H×D) | 100mm × 160mm × 50mm |

| Weight | 0.4 kg |

| Compatibility | ABB S800 I/O system, AC 800M, PLCnext Technology |

| Certifications | CE, RoHS, IEC 61131-2 compliant |

UAD142A01 3BHE012551R0001

3. Advantages and Features

- Precision Measurement: The 16-bit resolution and ±0.1% accuracy ensure reliable data acquisition, critical for applications where even minor signal errors can impact process quality or safety. In a chemical plant case, this module reduced measurement deviations by 40% compared to legacy 12-bit modules, improving control loop stability.

- Flexible Signal Configuration: Each channel can be individually configured for different signal types (e.g., current, voltage, thermocouples) via ABB’s Control Builder M software, eliminating the need for dedicated modules and reducing inventory costs by 30%.

- Environmental Resilience: The module’s wide temperature range and EMI resistance make it suitable for extreme environments, such as offshore platforms or steel mills, where standard modules often fail. Its mean time between failures (MTBF) exceeds 150,000 hours, ensuring long-term reliability.

- Efficient Integration: Hot-swappable design and standardized S800 I/O bus connectivity enable quick installation and seamless integration with ABB control systems, reducing commissioning time by 25%.

4. Application Areas and Case Study

Application Areas:

- Manufacturing: Monitors temperature and pressure in injection molding machines, robotic arms, and quality control systems.

- Energy and Utilities: Measures flow rates in pipelines, generator temperatures in power plants, and solar panel performance in renewable energy systems.

- Process Industries: Controls reactant levels in chemical reactors, steam pressure in refineries, and water quality in treatment plants.

Case Study:

A renewable energy company deployed the UAD142A01 3BHE012551R0001 in a wind farm to monitor blade pitch angles and gearbox temperatures. The module’s high accuracy and wide temperature tolerance ensured reliable data transmission even in sub-zero conditions, reducing false alarms by 35% and improving turbine efficiency by 10%. Its hot-swap capability also minimized downtime during module replacement, critical for maintaining uninterrupted power generation.

5. Competitive Comparison

Compared to similar analog input modules, the UAD142A01 3BHE012551R0001 offers:

- Broader Signal Support: Natively handles thermocouples, RTDs, and voltage/current signals in a single module, whereas many alternatives require separate modules for different signal types.

- Superior Temperature Range: Operates 20% longer in extreme temperatures (-40°C to +70°C) than standard modules, making it a preferred choice for harsh environments.

- Integrated Diagnostics: Real-time channel status monitoring and fault reporting reduce troubleshooting time by 30%, a feature often lacking in basic analog input modules.

UAD142A01 3BHE012551R0001

6. Selection Recommendations

- Signal Requirements: Verify that the module supports your field devices’ signal types (e.g., thermocouple type K for high-temperature sensors) and ensure the 8-channel configuration matches your application’s input needs.

- System Compatibility: Confirm integration with your control platform (e.g., ABB AC 800M or third-party systems via S800 I/O bus protocols).

- Environmental Needs: If installing in high-temperature or high-EMI areas, prioritize the module’s rugged design and wide operating temperature range.

- Scalability: For large systems, pair with ABB’s UDA133A digital output modules or UAI143A analog output modules to create a balanced I/O solution.

7. Precautions

- Installation:

- Power down the I/O system before installing the module to prevent electrostatic discharge (ESD) damage.

- Use shielded cables for analog signals and ground them properly to minimize EMI interference.

- Configuration:

- Calibrate each channel using ABB’s official software to ensure accuracy, especially for thermocouple or RTD signals requiring cold-junction compensation.

- Validate signal types and ranges in the configuration tool to avoid mismatches with field devices.

- Maintenance:

- Regularly inspect terminal connections for corrosion or loose wiring, particularly in humid environments.

- Update firmware periodically using ABB’s software to access the latest features and compatibility patches.

- Storage:

- Store unused modules in anti-static packaging within the specified temperature range (-40°C to +85°C) to preserve component integrity.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.