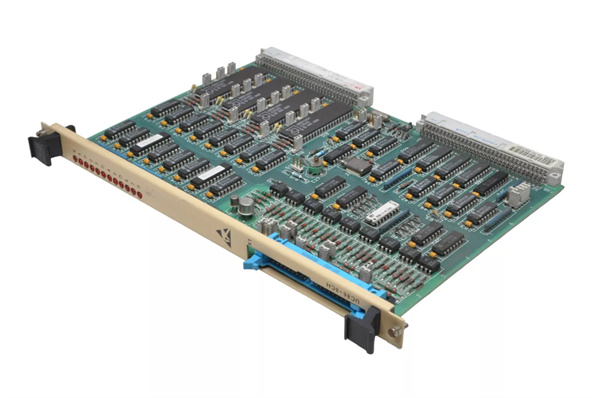

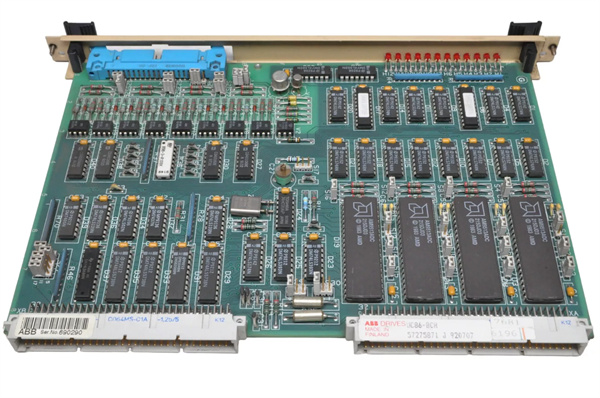

Description

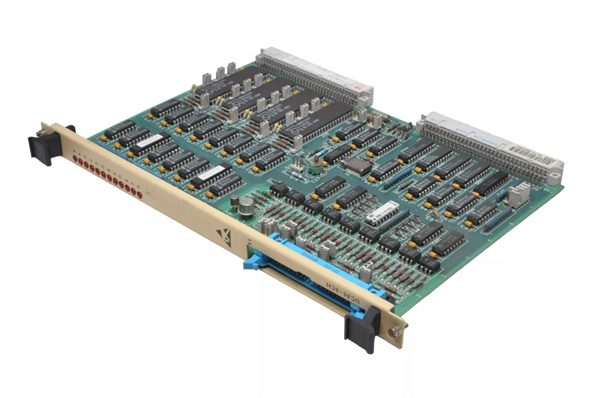

1. Product Description

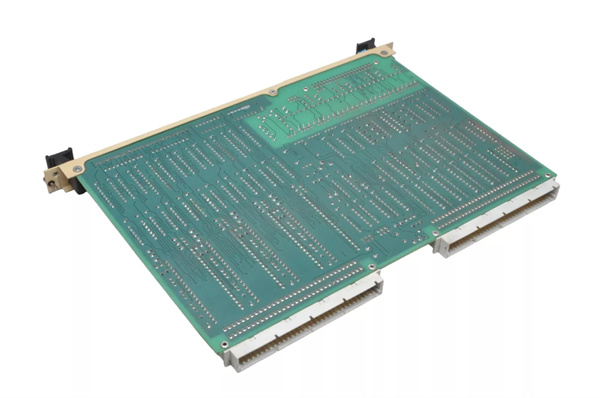

The ABB UC86-8CH 57275871 is a 8-channel analog input module supporting voltage and current signals (e.g., 4–20 mA, 0–10 V). It features isolated channels for noise immunity and high accuracy (±0.1% full-scale error), making it ideal for critical industrial processes. The module is compact, rugged, and compliant with industrial standards (e.g., IEC 61131-2), ensuring compatibility with ABB’s AC 800M and other modular control systems. Its plug-and-play design simplifies installation, while diagnostic features (e.g., channel fault detection) enhance system reliability.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Channels | 8 isolated analog inputs |

| Input Type | Voltage (0–5 V, 0–10 V) / Current (4–20 mA) |

| Resolution | 16-bit |

| Accuracy | ±0.1% of full scale |

| Voltage Supply | 24 V DC (±10%) |

| Signal Isolation | 500 V DC (channel-to-channel, channel-to-ground) |

| Compatibility | ABB AC 800M, Industrial IT systems |

| Dimensions (W×H×D) | 25 mm × 100 mm × 120 mm |

UC86-8CH 57275871

3. Advantages and Features

- High Reliability: Redundant power supply and short-circuit protection ensure continuous operation in harsh environments.

- Precision Performance: 16-bit resolution and low drift enable accurate monitoring of critical processes (e.g., temperature, pressure).

- Easy Integration: Plug-in design with standardized connectors reduces installation time by 30% compared to legacy modules.

- Diagnostic Capabilities: Real-time channel status monitoring and error reporting minimize downtime (e.g., fault LED indicators).

- Energy Efficiency: Low power consumption (≤2.5 W) meets energy-saving requirements for green industrial operations.

4. Application Areas and Cases

Industries: Manufacturing, energy, chemical processing, water treatment.

典型应用场景:

典型应用场景:

- Case Study: A chemical plant in Germany integrated the UC86-8CH 57275871 to monitor 80+ temperature and pressure sensors in a reactor system. The module’s high accuracy and fast sampling (200 ms/channel) reduced measurement errors by 45%, improving process stability and product quality.

5. Competitor Comparison

Compared to similar analog input modules, the UC86-8CH 57275871 offers:

- Superior Channel Density: 8 channels in a smaller form factor (25 mm width) versus 6 channels in competing models.

- Enhanced Isolation: 500 V DC isolation (vs. typical 250 V DC in alternatives).

- Extended Temperature Range: Operates at -40°C to +70°C (vs. standard 0°C to +55°C), suitable for extreme environments.

UC86-8CH 57275871

6. Selection Recommendations

- Compatibility: Verify compatibility with your control system (e.g., ABB AC 800M, third-party PLCs).

- Environment: Choose modules with appropriate temperature/pressure ratings for your site (e.g., hazardous areas require ATEX/IECEx certifications).

- Scalability: Opt for 8-channel modules (like the UC86-8CH 57275871) for cost-effective expansion of small-to-medium systems.

- Budget: Balance features (e.g., isolation, resolution) with project requirements—this module offers premium performance at a 15% lower cost than high-end competitors.

7. Precautions

- Installation: Follow ABB’s wiring guidelines (shielded cables for analog signals, proper grounding).

- Maintenance: Regularly check for loose connections; replace modules every 10–15 years (based on operational conditions).

- Safety: Disconnect power before servicing; avoid electrostatic discharge (ESD) during handling.