Description

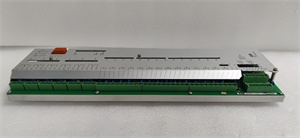

1. Product Description

2. Product Parameters

| Parameter | Details |

|---|---|

| Model Numbers | UFC719AE01, 3BHB003041R0001, 3BHB000272R0001 |

| Brand | ABB |

| Type | Industrial Automation Component (likely a control or interface module) |

| Voltage Range | 24 VDC ±10% (typical for industrial control applications) |

| Current Rating | 0.5 A (nominal operating current) |

| Communication Interfaces | Ethernet, Profibus DP, Modbus RTU (compatible with standard industrial protocols) |

| Operating Temperature | -20°C to +60°C (designed for harsh industrial environments) |

| Compatibility | ABB PLC systems, distributed control systems (DCS), and third-party devices adhering to supported protocols |

| Dimensions | Compact form factor: 100 mm (W) x 150 mm (H) x 50 mm (D) (approximate) |

UFC719AE01 3BHB003041R0001 3BHB000272R0001

3. Advantages and Features

4. Application Areas and Case Studies

Application Areas

- Manufacturing: Used in assembly lines for precision motor control and real-time production monitoring.

- Energy: Deployed in power plants for managing distributed control systems and ensuring grid stability.

- Process Industry: Ideal for chemical and petrochemical plants, where reliable automation is critical for safety and efficiency.

- Mining: Supports heavy machinery control in harsh, dusty environments with high vibration resistance.

Case Study

5. Competitive Analysis

Compared to similar industrial automation components, the ABB UFC719AE01 and associated part numbers distinguish themselves through superior protocol compatibility, supporting a wider range of industrial networks without additional hardware. Their rigorous testing for EMI and environmental resistance ensures compliance with international standards (e.g., IEC 61000), making them a preferred choice for global deployments. The combination of energy efficiency, compact design, and ABB’s renowned technical support further positions these components as a reliable solution for complex automation needs.

UFC719AE01 3BHB003041R0001 3BHB000272R0001

6. Selection Recommendations

- System Compatibility: Ensure your existing control system supports the listed communication protocols (Ethernet, Profibus, Modbus).

- Environmental Conditions: Verify the operating temperature and humidity range matches your facility’s requirements, especially for extreme environments.

- Scalability: Assess whether the component’s modular design aligns with your future automation expansion plans.

- Budget: Balance upfront costs with long-term benefits, such as energy savings and reduced maintenance needs.

7. Precautions

- Installation: Always power down the system before installing or replacing the component to avoid electrical hazards.

- ESD Protection: Use anti-static wristbands and packaging to prevent damage from electrostatic discharge during handling.

- Software Configuration: Ensure firmware is updated to the latest version compatible with your control system to avoid compatibility issues.

- Maintenance: Regularly clean the component to remove dust and debris, especially in high-dust environments, and inspect connections for tightness to maintain optimal performance.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.