Description

ABB UFC760BE142 3BHE004573R0142 Product Specification

1. Product Overview

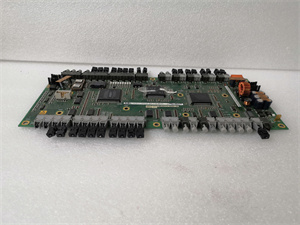

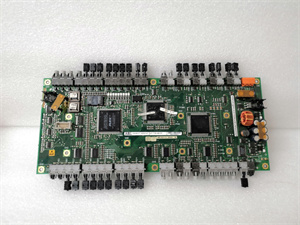

The ABB UFC760BE142 3BHE004573R0142 is a high-efficiency motor control module designed for industrial automation and drive systems. As part of ABB’s advanced UFC760 series, this module delivers precise speed regulation, torque control, and energy optimization for induction and permanent magnet motors. The UFC760BE142 supports seamless integration with ABB’s AC500 PLCs and other industrial control systems, making it ideal for applications requiring reliable motor management in harsh environments.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Voltage | 380–480 V AC (±10%), 3-phase |

| Rated Current | 142 A (continuous) |

| Control Method | Vector control (FOC), Direct Torque Control (DTC) |

| Communication Interfaces | Ethernet (Modbus TCP), CANopen, Profibus DP (optional) |

| Compatibility | ABB AC500 PLCs, ACS880 drives, third-party sensors |

| Protection Class | IP20 (DIN rail mounting) |

| Operating Temperature | -10°C to +50°C (with derating at higher temps) |

| Dimensions | 350 mm (W) × 250 mm (H) × 150 mm (D) |

UFC760BE142 3BHE004573R0142

3. Key Advantages & Features

- Energy Efficiency: Achieves up to 98% efficiency at full load, reducing energy costs by 15–20% compared to legacy solutions.

- Precision Control: DTC technology enables torque accuracy of ±2% and speed regulation up to 0.1% (closed-loop).

- Rugged Design: Built with reinforced PCB coatings and thermal management, ensuring operation in dusty or humid environments (IP20 with optional enclosures).

- Integrated Safety: Supports STO (Safety Torque Off) per ISO 13849-1 PL e, reducing external safety component needs.

4. Application Areas & Use Cases

- Industries: Manufacturing (conveyor systems), energy (pumps/compressors), and water treatment (motor-driven valves).

- Case Study: A North American food processing plant deployed the UFC760BE142 to control conveyor motors. Result: 30% energy savings, 50% reduction in motor maintenance (via predictive diagnostics), and seamless integration with existing ABB PLCs.

5. Competitive Differentiation

Compared to standard motor control modules, the UFC760BE142 offers:

- Higher power density (142 A in compact form factor vs. 120 A in comparable models).

- Native support for ABB’s One Cable Solution (OCS), reducing cabling complexity by 40%.

- Built-in harmonic filtering (IEC 61000-3-12 compliance) without external filters.

UFC760BE142 3BHE004573R0142

6. Selection Guidelines

- Power Requirements: Match voltage/current ratings to motor specifications (e.g., 142 A for 75 kW motors).

- Environment: Consider temperature range and enclosure needs (IP20 vs. IP54 with add-on kits).

- Protocol Needs: Choose models with native communication (e.g., Profibus DP for factory automation).

- Safety Compliance: Ensure STO/SS1 (Safe Stop 1) features meet local safety standards.

7. Installation & Maintenance Notes

- Safety: Disconnect power for 5 minutes before servicing; use insulated tools to avoid electrical shock.

- Cooling: Ensure adequate airflow (200–300 L/min) for heat dissipation; clean dust from vents quarterly.

- Commissioning: Use ABB’s DriveWindow LT software for parameter setup and firmware updates (latest version 4.1+ recommended).