Description

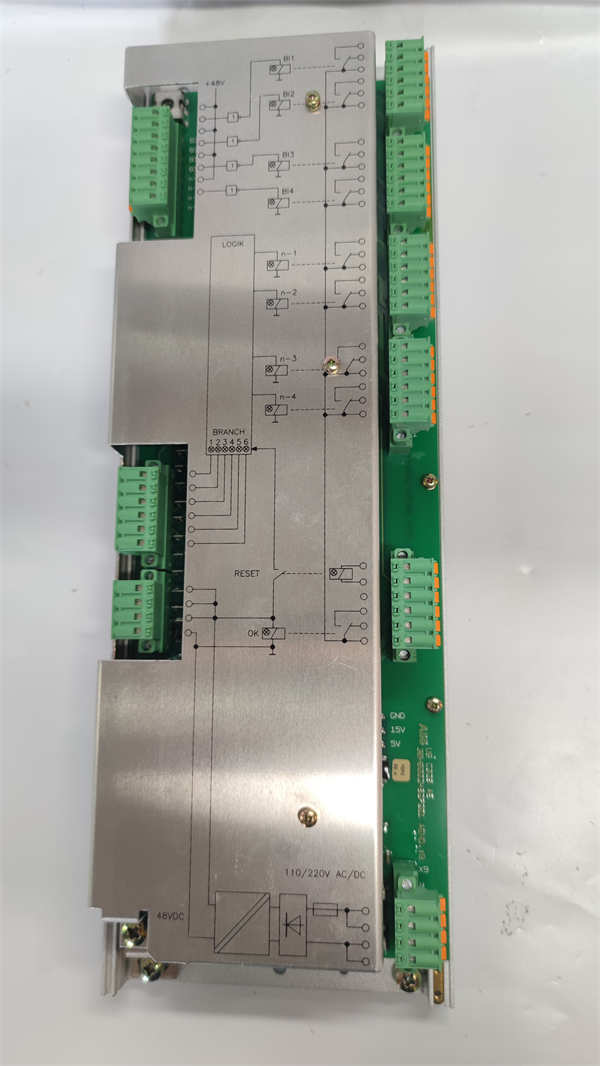

ABB USC329AE01 3HB002483R0001: High-Performance Control Module for Industrial Automation

1. Product Overview

The USC329AE01 3HB002483R0001 is a versatile control module designed by ABB for critical industrial applications. This module serves as a key component in distributed control systems (DCS) and programmable logic controllers (PLCs), providing reliable performance in manufacturing, energy, and process industries. It is engineered to handle complex control tasks, real-time data processing, and communication with external devices, ensuring seamless integration into existing automation setups.

The USC329AE01 3HB002483R0001 is part of ABB’s advanced control portfolio, offering compatibility with ABB’s AC 800PEC and AC 800M systems. Its modular design and rugged construction make it suitable for harsh environments, including extreme temperatures and high-vibration settings.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Voltage Range | 24V DC ±10% |

| Power Consumption | ≤15W |

| Communication Interfaces | Ethernet (10/100 Mbps), RS-485, Profibus DP |

| Input/Output Channels | 8 configurable I/O slots |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions | 145 mm (W) x 450 mm (H) x 100 mm (D) |

| Weight | 0.8 kg |

| Compatibility | ABB AC 800PEC/AC 800M systems, third-party devices via standard protocols |

USC329AE01 3HB002483R0001

3. Advantages and Features

- High Reliability: Built with robust components, the USC329AE01 3HB002483R0001 features an average time between failures (MTBF) exceeding 100,000 hours, minimizing downtime in critical operations.

- Flexible Integration: Supports multiple communication protocols (e.g., Ethernet, Profibus DP), enabling seamless connectivity with both ABB systems and third-party devices.

- Wide Operational Range: Designed to withstand extreme temperatures (-40°C to +70°C) and harsh industrial environments, making it ideal for oil refineries, power plants, and manufacturing facilities.

- Efficient Data Handling: Equipped with a high-speed processor, it can manage up to 1,000 I/O points simultaneously, ensuring real-time control and rapid response to process changes.

- Modular Design: Hot-swap functionality allows for easy maintenance and system expansion without disrupting operations.

4. Application Areas and Case Study

Application Areas

The USC329AE01 3HB002483R0001 is widely used in industries requiring precise automation control, including:

- Manufacturing: Robotics, conveyor systems, and quality control.

- Energy: Power generation, renewable energy systems, and grid stabilization.

- Chemical and Petrochemical: Process control, safety interlocks, and distillation units.

- Water Treatment: Pump stations and purification systems.

Case Study

A leading chemical plant in Europe integrated the USC329AE01 3HB002483R0001 into its distillation unit to optimize process control. The module’s ability to handle real-time data from temperature sensors, pressure transducers, and valves reduced energy consumption by 15% and improved production yield by 10%. Its rugged design also minimized maintenance needs, resulting in a 20% reduction in downtime over two years.

5. Competitive Comparison

Compared to similar PLC modules on the market, the USC329AE01 3HB002483R0001 stands out for its:

- Temperature Tolerance: Operates in extreme conditions (-40°C to +70°C), whereas many competitors are limited to narrower ranges.

- Protocol Flexibility: Supports multiple communication standards, reducing the need for custom adapters.

- Scalability: Expandable architecture allows integration with up to 16 additional modules, offering greater flexibility than rigid competitor platforms.

- Cost Efficiency: Lower power consumption (≤15W) and high MTBF translate to reduced long-term operational costs.

USC329AE01 3HB002483R0001

6. Selection Recommendations

When selecting the USC329AE01 3HB002483R0001 or similar modules, consider the following:

- Compatibility: Ensure alignment with your existing control system (e.g., ABB AC 800PEC) and required communication protocols.

- Environmental Conditions: Verify durability for extreme temperatures or high-vibration environments.

- Scalability: Assess future I/O requirements to avoid limitations in system expansion.

- Budget: Balance performance needs with cost, factoring in energy efficiency and maintenance costs.

7. Precautions

- Installation: Power down the system before installing/removing the module to prevent electrical damage. Use anti-static wrist straps to avoid electrostatic discharge (ESD).

- Maintenance: Regularly clean vents to prevent dust accumulation and update firmware as recommended by ABB.

- Safety Compliance: Ensure compliance with local safety standards (e.g., CE, UL) before deployment.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.