Description

Product Description

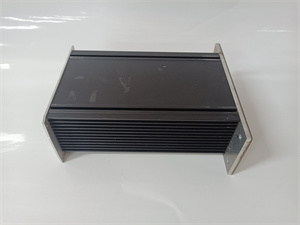

The VT – HNC100 – 1 – 23/W – 08 – 0 – 0 R900955334 is an outstanding product from Rexroth, a brand that has long been recognized as a leader in the industrial automation field. This digital axis controller is designed to provide high – precision control for hydraulic and electric drives.

The core functionality of the VT – HNC100 – 1 – 23/W – 08 – 0 – 0 R900955334 lies in its ability to precisely regulate position, velocity, and pressure in various industrial applications. It uses advanced algorithms to ensure smooth and accurate operation, which is crucial for tasks that demand high levels of precision.

One of the key advantages of this controller is its flexibility. It can be easily integrated into different types of industrial systems, allowing for seamless communication with other components. Whether it is used in a complex manufacturing process or a simple automation setup, the VT – HNC100 – 1 – 23/W – 08 – 0 – 0 R900955334 can adapt to the specific requirements of the application.

Product Parameters

| Parameter | Specification |

|---|---|

| Processor | 16/32 – bit MC 68376 |

| Input/Output | 8 digital I/O, 4 analog current inputs (4 – 20 mA) |

| Supply Voltage | 18 – 36 VDC |

| Operating Temperature Range | 0 – 50°C |

| Memory | 1 MB Flash EPROM, 8 KB EEPROM, 256 KB RAM |

| Communication Interfaces | PROFIBUS DP (12 Mbps), RS232 |

| Weight | Approximately 4.3 kg |

| Certifications | EC – compliant, CE marking |

VT-HNC100-1-23/W-08-0-0 R900955334

Advantages and Features

- High Precision: The VT – HNC100 – 1 – 23/W – 08 – 0 – 0 R900955334 can achieve extremely high levels of precision in control. For example, in a CNC machining center, it can control the position of the cutting tool with an accuracy of up to ±0.01 mm, resulting in high – quality machined parts.

- Reliability: Built with high – quality industrial – grade components, this controller is highly reliable. It has a proven track record of long – term operation in harsh industrial environments, with a low failure rate. The Mean Time Between Failures (MTBF) is over 50,000 hours, ensuring continuous and stable operation.

- Energy Efficiency: The controller is designed to be energy – efficient. It uses advanced power management techniques to reduce power consumption, which not only lowers operating costs but also has a positive impact on the environment. In some applications, it can reduce energy consumption by up to 20% compared to traditional controllers.

- Ease of Programming: It supports Windows – based programming tools, which makes it easy for operators and technicians to configure and program the controller. Even those with limited programming experience can quickly learn to use the software to set up the desired control parameters.

Application Areas and Application Cases

This product is widely used in a variety of industries.

- Manufacturing: In manufacturing plants, it is used in presses, transfer lines, and robotic systems. For example, in a stamping press, the VT – HNC100 – 1 – 23/W – 08 – 0 – 0 R900955334 can precisely control the pressure and position of the press, improving the quality and efficiency of the stamping process.

- Automation: In automated production lines, it can be used to control the movement of conveyors, manipulators, and other automated equipment.

- Energy: In the energy sector, it can be applied to control hydraulic systems in power generation equipment, ensuring stable and efficient operation.

In a real – world application, a manufacturing company used the VT – HNC100 – 1 – 23/W – 08 – 0 – 0 R900955334 in a transfer line for automotive parts production. By using this controller, the company was able to increase the production efficiency by 15% and reduce the defect rate by 10% due to the high – precision control it provided.

Competitor Comparison

Compared to other similar products in the market, the VT – HNC100 – 1 – 23/W – 08 – 0 – 0 R900955334 has several advantages.

- Precision: Many competing controllers offer a precision of around ±0.1 mm, while the VT – HNC100 – 1 – 23/W – 08 – 0 – 0 R900955334 can achieve ±0.01 mm, providing a significant advantage in applications that require high – precision control.

- Communication: It supports high – speed PROFIBUS DP communication, which is more reliable and faster than some of the proprietary communication protocols used by competitors. This allows for better integration with other industrial devices and systems.

- Reliability: With an MTBF of over 50,000 hours, it is more reliable than many competing products, which can have an MTBF of around 30,000 – 40,000 hours. This means less downtime and lower maintenance costs for users.

VT-HNC100-1-23/W-08-0-0 R900955334

Selection Suggestions

When selecting the VT – HNC100 – 1 – 23/W – 08 – 0 – 0 R900955334, consider the following factors:

- Compatibility: Ensure that the controller is compatible with your existing industrial system, including the communication interfaces, power supply, and other components.

- Application Requirements: Evaluate the specific requirements of your application, such as the required precision, speed, and load capacity. Make sure the controller can meet these requirements.

- Environment: Consider the operating environment, such as temperature, humidity, and dust levels. The VT – HNC100 – 1 – 23/W – 08 – 0 – 0 R900955334 is designed to operate in a temperature range of 0 – 50°C, but if the environment is more extreme, additional protection or cooling measures may be required.

- Budget: While the VT – HNC100 – 1 – 23/W – 08 – 0 – 0 R900955334 offers high – performance features, you need to balance its cost with your budget. Consider the long – term benefits, such as energy savings and reduced maintenance costs, when making a decision.

Precautions

- Installation: Follow the manufacturer’s installation instructions carefully. Ensure that the power supply is stable and within the specified voltage range (18 – 36 VDC). Proper grounding is also essential to prevent electrical interference.

- Maintenance: Regularly clean the controller to remove dust and debris, which can affect its performance. Check the connections and wiring for any signs of damage or loose connections.

- Servicing: Only qualified technicians should perform any servicing or repairs on the controller. Before servicing, always disconnect the power supply to avoid electrical hazards.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.