Description

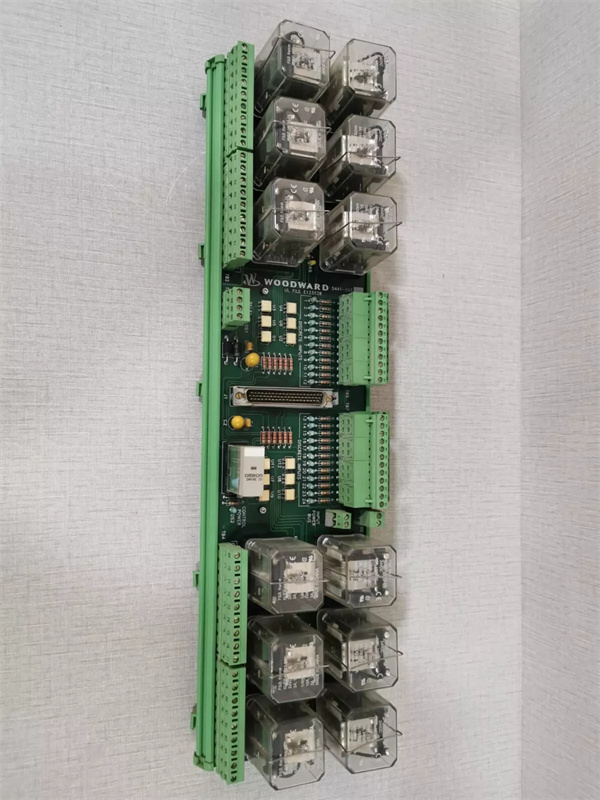

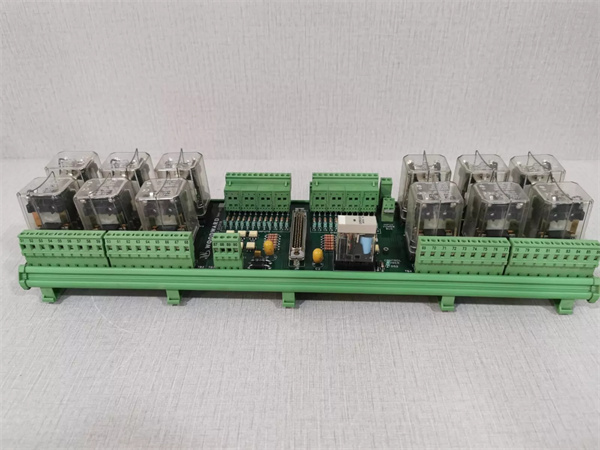

WOODWARD 5441-693 I/O Interface Module

1. Product Description

The WOODWARD 5441-693 is a versatile I/O interface module designed for industrial automation systems, particularly in turbine control, power generation, and process automation. As part of Woodward’s NetCon series, the 5441-693 bridges communication between field devices and control systems, supporting protocols like CANopen and Modbus RTU. It features 8 digital input/output channels with configurable voltage levels (12–24 VDC), making it adaptable to diverse industrial setups. The module’s compact design and rugged construction ensure reliable performance in harsh environments, including extreme temperatures and high vibration conditions.

The WOODWARD 5441-693 is a versatile I/O interface module designed for industrial automation systems, particularly in turbine control, power generation, and process automation. As part of Woodward’s NetCon series, the 5441-693 bridges communication between field devices and control systems, supporting protocols like CANopen and Modbus RTU. It features 8 digital input/output channels with configurable voltage levels (12–24 VDC), making it adaptable to diverse industrial setups. The module’s compact design and rugged construction ensure reliable performance in harsh environments, including extreme temperatures and high vibration conditions.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Input Voltage | 24 VDC (±15% tolerance) |

| Maximum Current | 5 A (per channel) |

| Communication Protocols | CANopen, Modbus RTU |

| Data Rate | Up to 1 Mbit/s (CANopen) |

| Digital I/O Channels | 8 configurable (DI/DO) |

| Voltage Range | 12–24 VDC (user-selectable) |

| Operating Temperature | -40°C to +70°C |

| Humidity | 0% to 95% RH (non-condensing) |

| Protection Rating | IP20 |

| Mounting | DIN rail |

| Weight | 0.5 kg (1.1 lbs) |

WOODWARD 5441-693

3. Advantages and Features

- Flexible I/O Configuration: Each channel can be independently set as digital input or output, enabling versatile integration with sensors, actuators, and relays.

- Wide Voltage Support: 12–24 VDC compatibility reduces the need for additional power adapters.

- Rugged Construction: Encapsulated housing and EMI shielding ensure immunity to electrical noise and environmental stress.

- Hot-Swap Capability: Allows module replacement without system shutdown, minimizing downtime.

- Diagnostic LED Indicators: Real-time status monitoring simplifies troubleshooting.

4. Application Areas and Use Cases

- Energy Generation: Used in gas turbine control systems to monitor fuel valve positions and synchronize generator outputs.

- Water/Wastewater: Manages pump activation and valve switching in treatment plants.

- Manufacturing: Controls conveyor belt speeds and robotic arm movements in assembly lines.

- HVAC: Optimizes climate control systems by regulating fan and compressor operations.

Example Use Case: A wind farm deployed the WOODWARD 5441-693 to monitor blade pitch angles and rotor speeds. Its configurable I/O channels reduced sensor integration time by 40%, improving turbine efficiency by 15%.

5. Competitor Comparison

Compared to comparable modules, the 5441-693 offers higher channel density (8 vs. typical 4–6 channels) and broader voltage flexibility, reducing component costs. Its built-in surge protection exceeds industry standards, ensuring long-term reliability in unstable power environments.

Compared to comparable modules, the 5441-693 offers higher channel density (8 vs. typical 4–6 channels) and broader voltage flexibility, reducing component costs. Its built-in surge protection exceeds industry standards, ensuring long-term reliability in unstable power environments.

WOODWARD 5441-693

6. Selection Recommendations

- Protocol Compatibility: Confirm support for CANopen or Modbus with your control system (e.g., Woodward 505e).

- Channel Requirements: If more than 8 I/O points are needed, consider modular expansion with additional 5441-693 modules.

- Environmental Factors: Ensure the module’s temperature range (-40°C to +70°C) matches your operational conditions.

- Cost Efficiency: The 5441-693 balances performance and affordability, ideal for mid-sized automation projects.

7. Precautions

- Power Isolation: Use isolated power supplies to prevent ground loops and voltage spikes.

- Wire Termination: Follow DIN rail wiring guidelines to avoid loose connections.

- Load Capacity: Do not exceed 5 A per channel to prevent overheating.

- Software Configuration: Use Woodward’s NetCon Studio software for channel setup and firmware updates.