Description

1. Product Description

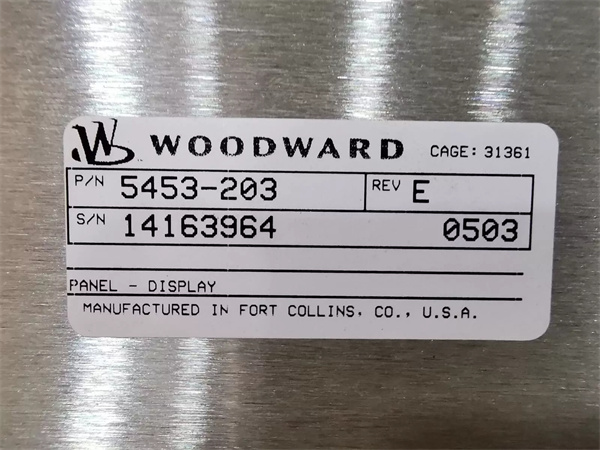

The WOODWARD 5453-203 is a Micronet Control Module designed for industrial automation, offering precise control over motor speeds and process parameters. As part of Woodward’s Micronet series, the 5453-203 integrates advanced signal processing and communication capabilities to ensure reliable operation in challenging environments. Key features include support for Modbus RTU and Ethernet protocols, 16 input channels, and 8 output channels, making it suitable for applications such as turbine control, power generation, and machinery automation.

The WOODWARD 5453-203 is a Micronet Control Module designed for industrial automation, offering precise control over motor speeds and process parameters. As part of Woodward’s Micronet series, the 5453-203 integrates advanced signal processing and communication capabilities to ensure reliable operation in challenging environments. Key features include support for Modbus RTU and Ethernet protocols, 16 input channels, and 8 output channels, making it suitable for applications such as turbine control, power generation, and machinery automation.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | 5453-203 |

| Type | Micronet Control Module |

| Input Voltage | 220V AC |

| Output Frequency | 50 Hz |

| Communication Interfaces | RS-485, Ethernet (Modbus RTU/TCP) |

| Input/Output Channels | 16 inputs / 8 outputs |

| Operating Temperature | -20°C to +70°C |

| Protection Rating | IP65 (dust and water resistance) |

| Weight | 2.5 kg |

| Certifications | CE, UL |

WOODWARD 5453-203

3. Advantages and Features

- Precision Control: PID algorithm ensures accurate speed regulation for motors and engines.

- Flexible Communication: Supports both RS-485 and Ethernet for seamless integration with DCS/PLC systems.

- Rugged Design: IP65 rating protects against dust and water, ideal for harsh industrial settings.

- Modular Scalability: Expandable architecture allows easy integration with additional I/O modules.

- Energy Efficiency: Low power consumption reduces operational costs.

4. Application Areas and Case Studies

- Power Generation: Controls steam turbine speeds in power plants for stable energy output.

- Manufacturing: Optimizes conveyor systems in automotive assembly lines for precise motion control.

- Oil and Gas: Manages pump speeds in refineries to enhance process efficiency.

- Case Study: A European manufacturing plant reduced energy costs by 15% using the 5453-203 to dynamically adjust motor speeds based on production demands.

5. Competitor Comparison

Compared to similar modules, the 5453-203 offers a broader operating temperature range (-20°C to +70°C vs. typical -10°C to +60°C) and dual communication interfaces, enabling versatile system integration. Its IP65 rating exceeds many alternatives, ensuring durability in wet or dusty environments.

WOODWARD 5453-203

6. Selection Recommendations

- Voltage Requirements: Ensure compatibility with 220V AC power supply.

- Environmental Demands: Choose IP65-rated modules for outdoor or high-moisture applications.

- Channel Needs: Verify input/output channel count matches system requirements.

7. Precautions

- Installation: Follow grounding guidelines to prevent EMI interference.

- Power Management: Avoid exceeding current ratings to prevent overheating.

- Software Updates: Regularly update firmware for optimal performance and security.

- Discontinuation Note: The 5453-203 is discontinued; consider upgrading to Woodward’s newer Micronet Plus series for long-term support.