Description

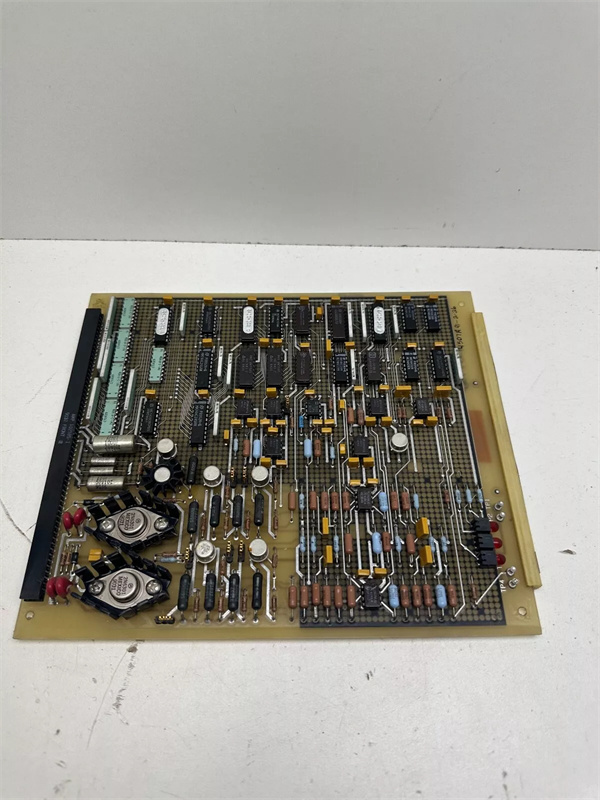

WOODWARD 5461-655 Final Driver Module

1. Product Description

The WOODWARD 5461-655 is a high-performance final driver module designed to interface control systems with industrial actuators, valves, and motors. As part of Woodward’s advanced automation portfolio, this module translates control signals into precise mechanical movements, ensuring reliable operation in critical applications. With a compact design and robust construction, the 5461-655 supports seamless integration into power generation, oil & gas, and process control systems. Its isolated outputs and surge protection enhance safety and durability in harsh environments, making it a trusted choice for mission-critical operations.

The WOODWARD 5461-655 is a high-performance final driver module designed to interface control systems with industrial actuators, valves, and motors. As part of Woodward’s advanced automation portfolio, this module translates control signals into precise mechanical movements, ensuring reliable operation in critical applications. With a compact design and robust construction, the 5461-655 supports seamless integration into power generation, oil & gas, and process control systems. Its isolated outputs and surge protection enhance safety and durability in harsh environments, making it a trusted choice for mission-critical operations.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Input Voltage | 24 VDC ±15% |

| Output Current | 10 A per channel (max) |

| Interface Type | Digital/analog hybrid |

| Compatibility | Woodward control systems (e.g., 505e, NetCon) |

| Operating Temperature | -40°C to +70°C |

| Protection | Overload, short-circuit, EMI shielding |

| Mounting | DIN rail |

| Weight | 0.3 kg (0.66 lbs) |

WOODWARD 5461-655

3. Advantages and Features

- High Power Handling: Capable of driving high-current loads up to 10 A per channel, reducing the need for external amplifiers.

- Flexible Control: Supports both analog (0–10 VDC) and digital (24 VDC) input signals for versatile actuator management.

- Rugged Design: Encapsulated housing and conformal coating protect against moisture, dust, and vibration.

- Safety Features: Built-in overcurrent and short-circuit protection prevent system damage.

- Easy Integration: Plug-and-play compatibility with Woodward’s control platforms minimizes setup time.

4. Application Areas and Use Cases

- Power Generation: Controls steam turbine valves to regulate energy output in thermal power plants.

- Oil & Gas: Manages choke valves in wellheads to optimize flow rates.

- Water Treatment: Actuates diaphragm valves in wastewater treatment systems.

- Manufacturing: Drives robotic arm movements in automated assembly lines.

Example Use Case: A petrochemical plant implemented the 5461-655 to control emergency shutdown valves. Its fast response time (<50 ms) and high reliability reduced downtime risks by 30%, ensuring compliance with safety standards.

5. Competitor Comparison

Compared to similar modules, the 5461-655 offers higher current capacity (10 A vs. typical 5–8 A) and integrated surge protection, eliminating the need for external safety components. Its modular design allows for easy expansion, reducing installation costs by up to 20% in large-scale projects.

Compared to similar modules, the 5461-655 offers higher current capacity (10 A vs. typical 5–8 A) and integrated surge protection, eliminating the need for external safety components. Its modular design allows for easy expansion, reducing installation costs by up to 20% in large-scale projects.

WOODWARD 5461-655

6. Selection Recommendations

- Load Requirements: Ensure the module’s 10 A output matches your actuator’s current draw.

- Control System Compatibility: Verify compatibility with your Woodward controller (e.g., 505e, NetCon).

- Environmental Conditions: Confirm the -40°C to +70°C temperature range aligns with your operational environment.

- Space Constraints: Its compact size (19.1 cm × 2.5 cm × 23.5 cm) makes it suitable for confined spaces.

7. Precautions

- Wiring Safety: Use shielded cables to prevent signal interference and ensure proper grounding.

- Current Management: Avoid exceeding 10 A per channel to prevent overheating.

- Maintenance: Regularly inspect terminals for corrosion or 松动 connections.

- Software Configuration: Calibrate the module using Woodward’s proprietary configuration tools for optimal performance.