Description

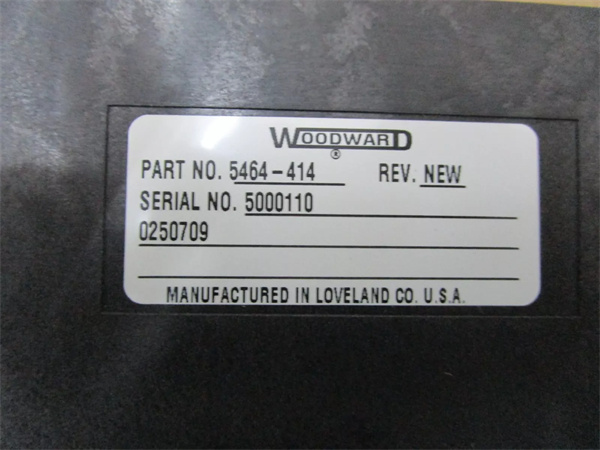

WOODWARD 5464 – 414

1. Product Description

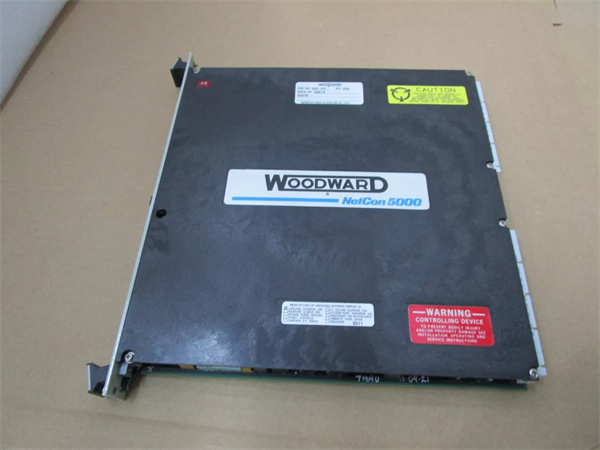

The WOODWARD 5464 – 414 is a highly advanced and reliable module in the field of industrial automation. It plays a crucial role in control systems, especially those related to power generation and industrial machinery. This module is designed to manage and regulate various parameters, ensuring the smooth and efficient operation of connected equipment. It can communicate with other devices in the system, process incoming data, and issue appropriate control commands. The WOODWARD 5464 – 414 is well – known for its compatibility with a wide range of Woodward control systems, making it a versatile choice for different applications. It is also built to withstand harsh industrial environments, providing long – term stability and performance.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Power Supply | 24 VDC ± 10% |

| Communication Interface | Ethernet, RS – 485 |

| Digital Inputs | 16 channels, 24 VDC compatible |

| Digital Outputs | 8 channels, 24 VDC, 1 A per channel |

| Analog Inputs | 4 channels, 0 – 10 VDC or 4 – 20 mA |

| Analog Outputs | 2 channels, 0 – 10 VDC or 4 – 20 mA |

| Operating Temperature Range | – 40°C to + 70°C |

| Storage Temperature Range | – 55°C to + 85°C |

| Dimensions | 170 mm x 100 mm x 50 mm |

| Weight | Approximately 1 kg |

WOODWARD 5464-414

3. Advantages and Features

- High – Speed Data Processing: The WOODWARD 5464 – 414 is equipped with a powerful processor that can handle large amounts of data in a short time. For example, it can process sensor data from multiple inputs and generate control signals within milliseconds, ensuring real – time control of industrial processes.

- Robust Design: It is designed to operate in harsh industrial environments. It can resist dust, moisture, and vibrations. In a mining project, the module has been proven to work stably for a long time in a dusty and high – vibration environment, reducing the frequency of maintenance and replacement.

- Easy Integration: With its standard communication interfaces (Ethernet and RS – 485), it can be easily integrated into existing control systems. This allows users to upgrade their systems without major overhauls, saving time and cost.

- Flexible I/O Configuration: The combination of digital and analog inputs and outputs provides great flexibility. Users can configure the module according to their specific application requirements, such as monitoring temperature, pressure, and flow, and controlling motors, valves, etc.

4. Application Areas and Application Cases

- Power Generation: In power plants, the WOODWARD 5464 – 414 can be used to monitor and control the operation of generators. It can adjust the output power according to the grid demand, ensuring the stability of the power supply. For example, in a hydro – power plant, the module is used to monitor the water flow rate, turbine speed, and generator output voltage. Based on this data, it can adjust the turbine blades to optimize the power generation efficiency.

- Industrial Manufacturing: In manufacturing plants, it can be used to control production lines. For instance, in an automotive manufacturing plant, the module can control the movement of robotic arms, monitor the quality of parts, and adjust the production speed according to the production plan.

- Oil and Gas Industry: In the oil and gas industry, it can be used to monitor and control the operation of pumps, compressors, and pipelines. It can detect abnormal conditions such as leaks and over – pressure, and take corresponding measures to ensure safety.

5. Competitor Comparison

Compared with similar products in the market, the WOODWARD 5464 – 414 has several advantages. Firstly, its high – speed data processing capability is superior to many competitors, which enables more accurate and real – time control. Secondly, its robust design allows it to operate in more severe environments, reducing the risk of system failures. Thirdly, its flexible I/O configuration provides more options for users, meeting a wider range of application requirements.

WOODWARD 5464-414

6. Selection Recommendations

- Compatibility: Ensure that the WOODWARD 5464 – 414 is compatible with your existing control system. Check the communication protocols, power supply requirements, and I/O interfaces to ensure seamless integration.

- Installation Environment: Consider the installation environment, such as temperature, humidity, dust, and vibration. If the environment is harsh, the module’s ability to withstand these conditions should be a key consideration.

- Budget: Compare the price of the module with your budget. However, do not sacrifice quality and performance for a lower price. Consider the long – term cost, including maintenance and replacement costs.

7. Precautions

- Installation: Follow the installation instructions carefully. Ensure proper grounding to prevent electrical interference. Make sure that the module is installed in a well – ventilated area to avoid overheating.

- Power Supply: Use a stable and reliable power supply. Avoid voltage fluctuations and power surges, which may damage the module.

- Maintenance: Regularly check the module for any signs of damage or malfunction. Clean the module regularly to prevent dust accumulation. Update the firmware regularly to ensure the best performance and security.