Description

1. Product Description

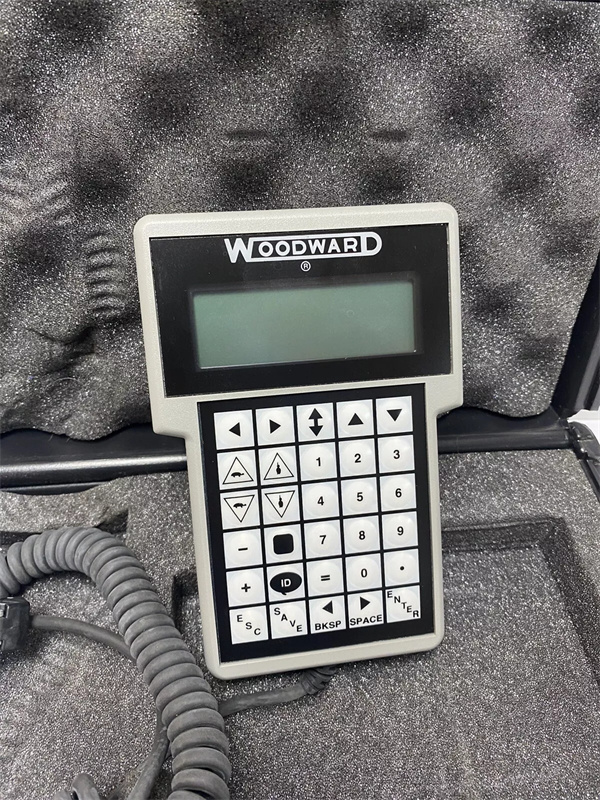

The Woodward 9907 – 205 is a high – performance electronic control module specifically designed for industrial applications. Woodward, a well – known brand in the field of industrial control, has engineered this module to provide precise control and monitoring capabilities.

The core function of the Woodward 9907 – 205 is to manage and regulate the operation of various industrial equipment, such as engines, turbines, and generators. It can process multiple input signals from sensors, including temperature, pressure, and speed sensors, and then generate appropriate control outputs to ensure the stable and efficient operation of the connected equipment.

One of the main advantages of the Woodward 9907 – 205 is its high level of reliability. It is built with robust components that can withstand harsh industrial environments, including high temperatures, vibrations, and electrical interference. Additionally, its user – friendly interface allows for easy configuration and programming, reducing the time and effort required for installation and setup.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Input Voltage | 12 – 24 VDC |

| Input Signals | Analog (e.g., 0 – 10 V, 4 – 20 mA) and Digital (ON/OFF) |

| Output Signals | Analog (e.g., 0 – 10 V, 4 – 20 mA) and Digital (Relay Outputs) |

| Communication Interface | RS – 485 (Modbus RTU) |

| Operating Temperature Range | – 40°C to + 70°C |

| Storage Temperature Range | – 55°C to + 85°C |

| Dimensions | 180 mm x 120 mm x 50 mm |

| Weight | Approximately 1 kg |

WOODWARD 9907-205

3. Advantages and Features

- High Reliability: With a Mean Time Between Failures (MTBF) of over 50,000 hours, the Woodward 9907 – 205 can operate continuously in industrial settings with minimal downtime. For example, in a power generation plant, it has been proven to run for long periods without any significant failures, ensuring stable power output.

- Flexible Input and Output Configuration: It supports a wide range of analog and digital input and output signals, allowing it to be easily integrated with different types of sensors and actuators. This flexibility makes it suitable for a variety of industrial applications.

- Advanced Communication: The RS – 485 communication interface with Modbus RTU protocol enables seamless integration with other control systems, such as Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems. This allows for centralized monitoring and control of the entire industrial process.

- Easy Configuration: The module comes with a user – friendly software tool that simplifies the configuration and programming process. Even non – technical personnel can quickly set up the module according to their specific requirements.

4. Application Areas and Application Cases

- Power Generation: In gas turbine power plants, the Woodward 9907 – 205 is used to control the speed and load of the turbines. By accurately regulating the fuel supply and blade pitch, it can optimize the power output and improve the overall efficiency of the power plant. For instance, a power plant in Europe installed the Woodward 9907 – 205 and achieved a 5% increase in power generation efficiency.

- Oil and Gas: In oil refineries and natural gas processing plants, the module is used to control the operation of pumps, compressors, and other equipment. It can monitor parameters such as pressure and flow rate and adjust the equipment’s operation accordingly to ensure safe and efficient production.

- Manufacturing: In manufacturing plants, the Woodward 9907 – 205 can be used to control conveyor belts, robotic arms, and other production equipment. By precisely controlling the speed and position of these devices, it can improve the quality and productivity of the manufacturing process.

5. Competitor Comparison

Compared to other similar products in the market, the Woodward 9907 – 205 offers several distinct advantages. Firstly, its wider operating temperature range (- 40°C to + 70°C) allows it to be used in more extreme environments. Secondly, its high – reliability design with a long MTBF reduces the need for frequent maintenance and replacement, resulting in lower overall costs. Additionally, the user – friendly configuration software makes it easier for users to set up and operate the module compared to some competitors’ products, which may require more technical expertise.

WOODWARD 9907-205

6. Selection Recommendations

- Compatibility: Before selecting the Woodward 9907 – 205, ensure that it is compatible with your existing sensors, actuators, and control systems. Check the input and output signal types, communication protocols, and voltage requirements.

- Installation Environment: Consider the temperature, humidity, and vibration levels of the installation environment. If the environment is harsh, the wide operating temperature range and robust design of the Woodward 9907 – 205 make it a suitable choice.

- Budget: While the Woodward 9907 – 205 offers high – quality and reliable performance, it is important to consider your budget. Compare the cost of the module with its features and benefits to ensure that it provides the best value for your investment.

7. 注意事项

- Installation: Follow the installation instructions provided in the user manual carefully. Ensure proper grounding and wiring to prevent electrical interference and short – circuits.

- Maintenance: Regularly inspect the module for any signs of damage or wear. Clean the module and its connectors to prevent dust and debris from affecting its performance.

- Safety: When operating and maintaining the module, follow all relevant safety regulations. Disconnect the power supply before performing any maintenance or repair work.