Description

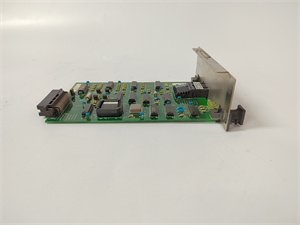

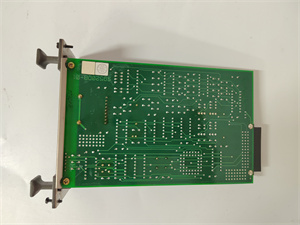

Product Specification: YOKOGAWA AIP578 Analog Input Module

The YOKOGAWA AIP578 is a high-performance analog input module designed for industrial process control systems, enabling precise signal acquisition from sensors and transmitters. Built with Yokogawa’s advanced technology, the AIP578 supports seamless integration into PLC and DCS networks, ensuring reliable data transmission in challenging industrial environments.

1. Product Description

The YOKOGAWA AIP578 serves as a versatile interface for converting analog signals into digital data for control systems. Key features include:

- Multi-channel Support: 8 isolated channels for simultaneous input from multiple sensors.

- Wide Signal Range: Accepts 4–20mA, 0–10V, and mV signals with ±0.1% accuracy.

- Electrical Isolation: 2500V DC isolation between channels and system ground to prevent noise interference.

- Hot-Swap Capability: Allows module replacement without powering down the system.

- Diagnostic Functions: Real-time monitoring of input signal status and module health.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Input Type | 4–20mA, 0–10V, mV |

| Channels | 8 (isolated) |

| Resolution | 16-bit |

| Accuracy | ±0.1% (at 25°C) |

| Input Impedance | 250Ω (for 4–20mA) |

| Power Supply | 24V DC ±10% |

| Operating Temperature | -20°C to +60°C |

| Dimensions | 125mm × 100mm × 50mm |

| Weight | 0.4kg |

| Certifications | CE, UL, IEC 61508 SIL 2 |

AIP578

3. Advantages and Features

- Reliability: MTBF of 150,000 hours ensures long-term operation in continuous processes.

- High Precision: ±0.1% accuracy minimizes measurement errors in critical applications.

- Space Efficiency: Compact design reduces cabinet space by 30% compared to legacy modules.

- Case Study: A chemical plant reduced calibration costs by 20% using AIP578 due to its stable signal performance.

4. Application Areas and Cases

- Process Control: Monitors temperature, pressure, and flow in oil refineries and petrochemical plants.

- Manufacturing: Collects data from machinery in automotive assembly lines for predictive maintenance.

- Energy: Supports real-time monitoring of renewable energy systems (e.g., solar farms).

- Case Study: A power plant achieved 99.8% uptime using AIP578 to track boiler parameters, preventing system failures.

-

AIP578

5. Competitor Comparison

The AIP578 outperforms alternatives with:

- Higher Channel Density: 8 channels vs. typical 4–6 channels in comparable modules.

- Lower Power Consumption: 2.5W total power vs. 3–4W in competitors.

- Enhanced Safety: SIL 2 certification for use in safety-critical systems.

6. Selection Recommendations

- Channel Requirements: Choose the AIP578 for 8-channel applications; opt for AIP578-2 for 16-channel configurations.

- Signal Type: Ensure compatibility with your sensor outputs (e.g., 4–20mA for transmitters).

- Environment: Select IP20-rated modules for indoor use; consider IP65 variants for outdoor installations.

7. Precautions

-

Cabling: Use shielded twisted-pair cables to minimize EMI interference.

-

Voltage Surges: Install surge protectors if exposed to transient voltage spikes.

-

Calibration: Perform annual calibration to maintain accuracy.

-

Software Compatibility: Verify PLC/DCS software compatibility before deployment.