Description

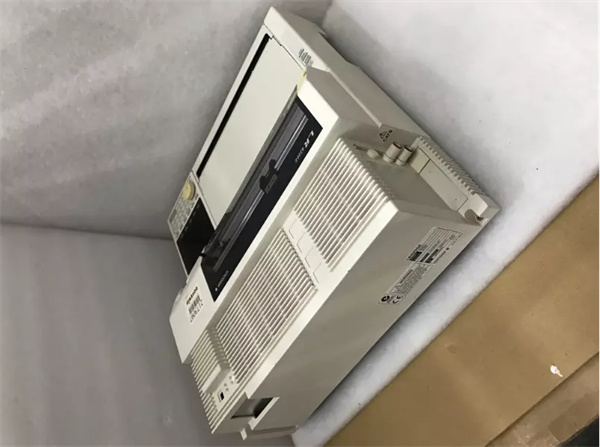

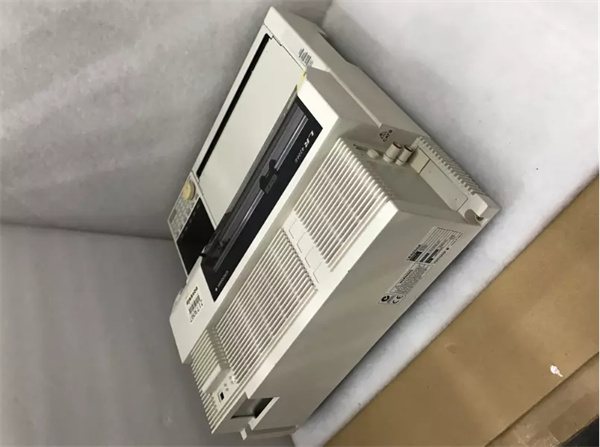

YOKOGAWA LR 4220E 2-Pen Strip Chart Recorder

1. Product Description

The YOKOGAWA LR 4220E is a discontinued 2-pen strip chart recorder designed for industrial data logging applications. Part of Yokogawa’s LR series, the LR 4220E records analog signals (voltage, current, temperature, etc.) on a 20-meter paper chart, offering real-time visualization of process data. With dual-channel recording, configurable chart speeds (10–600 mm/min), and support for DC voltage, thermocouple, and RTD inputs, it caters to diverse industries such as manufacturing, energy, and research. The recorder features alarm functions for threshold violations and a compact design (144 mm × 144 mm × 280 mm) for panel mounting. While now discontinued, it remains a reliable solution for legacy systems requiring analog data logging.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Channels | 2 (simultaneous recording) |

| Input Types | DC voltage (0–500 mV), thermocouples (J, K, T), RTD (Pt100) |

| Chart Speed | 10–600 mm/min (adjustable) |

| Paper Size | 20 m roll (standard width: 100 mm) |

| Alarm Function | Audible/visual alerts for out-of-range values |

| Power Supply | 100–240V AC (50/60Hz) |

| Dimensions | 144 mm (W) × 144 mm (H) × 280 mm (D) |

| Weight | 8 kg |

| Environmental Rating | IP20 (indoor use) |

| Certifications | CE, UL (compliant with industrial standards) |

3. Advantages and Features

- Multi-Channel Flexibility: Simultaneous 2-channel recording for complex processes.

- Versatile Inputs: Supports thermocouples, RTDs, and DC voltage, ideal for mixed-signal environments.

- User-Friendly Operation: Adjustable chart speeds and modular design for easy paper replacement and calibration.

- Alarm System: Real-time alerts for critical parameter deviations.

- Legacy Compatibility: Suitable for retrofitting into older control systems without digital upgrades.

YOKOGAWA LR 4220E

4. Application Areas and Case Studies

- Manufacturing: Monitoring temperature and pressure in production lines.

- Energy: Logging data from power generators and HVAC systems.

- Research Labs: Recording experimental data in chemical or material testing.

Case Study: A water treatment plant used the LR 4220E to monitor pH and conductivity in wastewater tanks. Its dual-channel capability allowed side-by-side analysis, while alarm functions triggered immediate responses to outliers. The analog format simplified integration with legacy SCADA systems, ensuring continuous operation during a phased digital upgrade.

5. Competitive Comparison

Against legacy chart recorders, the LR 4220E offers:

- Dual-Channel Efficiency: Simultaneous recording (vs. single-channel alternatives).

- Wide Input Range: Support for thermocouples/RTDs (vs. limited voltage-only models).

- Compact Design: Space-saving dimensions (144 mm × 144 mm) for crowded control panels.

- Cost-Effective Legacy Support: Lower maintenance costs compared to retrofitting digital systems.

6. Selection Recommendations

- Legacy Systems: Choose the LR 4220E for analog data logging in older installations.

- Replacement Planning: Consider Yokogawa’s modern alternatives (e.g., MW100/MX100 digital recorders) for new projects.

- Input Requirements: Verify compatibility with thermocouple/RTD types (e.g., J/K/T for thermocouples).

- Space Constraints: Ensure panel space (144 mm × 144 mm) and ventilation for continuous operation.

7. Installation and Usage Notes

-

Wiring: Use shielded cables for thermocouple/RTD inputs to reduce noise.

-

Paper Replacement: Replace rolls every ~200 hours (at 600 mm/min); store paper in dry environments.

-

Calibration: Perform annual checks using Yokogawa’s calibration tools (e.g., Model 370013 software).

-

Discontinuation: Plan for eventual replacement (end-of-life support may be limited).