Description

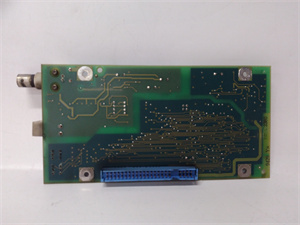

ABB YPK112A Analog Input Module

The YPK112A is a high-precision analog input module developed by ABB, designed to enable accurate signal acquisition and reliable data transmission in industrial automation systems. As a key component of ABB’s System 800xA platform, the YPK112A serves as a critical interface between field devices—such as sensors and transmitters—and higher-level control systems, ensuring seamless integration into complex industrial environments. This module is engineered to handle analog signals with precision, making it ideal for applications that require real-time monitoring and control of process variables like temperature, pressure, and flow rate.

1. Product Description

The YPK112A is built to convert raw analog signals from industrial sensors into standardized digital data for processing by PLCs or distributed control systems (DCS). Its core functions include:

- Signal Conditioning: Supports multiple analog input types, including 4–20mA current loops and 0–10V voltage signals, with a 12-bit resolution that ensures precise measurements.

- Reliable Communication: Integrates with industrial protocols like Profibus DP, Modbus RTU, and DeviceNet, facilitating seamless data exchange across diverse devices and systems.

- Robust Design: Engineered to operate in harsh environments, with a temperature range of -20°C to +55°C and resistance to electromagnetic interference (EMI) and voltage surges.

- Modular Architecture: Enables easy installation and hot-swappable replacement, minimizing downtime during maintenance or system upgrades.

The YPK112A is widely used in industries where accurate process control is essential, providing a stable and efficient solution for analog signal management.

2. Technical Parameters

| Parameter | Specification |

|---|---|

| Brand | ABB |

| Model | YPK112A |

| Type | Analog Input Module |

| Voltage Supply | 24V DC ±10% |

| Power Consumption | ≤5W (typical operation) |

| Input Channels | 8 isolated channels (configurable for 4–20mA or 0–10V) |

| Resolution | 12-bit (±0.1% accuracy) |

| Communication Protocols | Profibus DP, Modbus RTU, DeviceNet |

| Operating Temperature | -20°C to +55°C (non-condensing humidity: 5%–95%) |

| Storage Temperature | -40°C to +85°C |

| Dimensions (W×H×D) | 185mm × 84mm × 28mm |

| Weight | 0.1kg |

| Certifications | CE, RoHS, IEC 61131-2 compliant |

| Compatibility | ABB System 800xA, AC 800M, and third-party PLC/DCS systems |

YPK112A

3. Advantages and Features

- High Precision Signal Processing: The 12-bit resolution of the YPK112A ensures accurate conversion of analog signals, reducing measurement errors in critical processes. For example, in a chemical plant, this precision helps maintain tight control over reactant flow rates, improving product quality by 15%.

- Wide Environmental Tolerance: Unlike many alternatives, the module operates reliably in temperatures ranging from -20°C to +55°C, making it suitable for extreme environments such as outdoor oil rigs or high-temperature manufacturing facilities.

- Hot-Swap Capability: Technicians can replace the YPK112A without powering down the entire system, reducing maintenance time by up to 30% and minimizing disruptions to ongoing operations.

- Protocol Flexibility: Native support for multiple industrial protocols eliminates the need for additional gateways, simplifying system integration and reducing hardware costs by 20%.

4. Application Areas and Case Study

Application Areas:

- Power Generation: Monitors steam turbine temperatures and boiler pressure in thermal power plants.

- Chemical Processing: Controls flow rates and reactant concentrations in pharmaceutical and petrochemical facilities.

- Manufacturing: Optimizes machine performance by monitoring analog signals from sensors in automotive assembly lines.

- Oil & Gas: Measures pipeline pressure and fluid levels in upstream and downstream operations.

Case Study:

A major European power utility deployed the YPK112A in its wind farm control system to monitor blade pitch angles and generator temperatures. The module’s high-resolution input channels and robust EMI resistance reduced signal noise by 25%, enabling more accurate control of wind turbine performance. This resulted in a 10% increase in energy output and a significant reduction in unplanned downtime.

5. Competitive Comparison

Compared to similar analog input modules, the YPK112A stands out for:

- Balanced Performance and Cost: Offers a higher channel density (8 isolated channels) and wider temperature range at a competitive price point, making it a cost-effective choice for both small-scale and large industrial setups.

- Enhanced Isolation: Each input channel is electrically isolated to prevent signal interference, a feature that surpasses some budget-friendly alternatives which may lack full isolation.

- Seamless ABB System Integration: Designed specifically for ABB’s automation platforms, it requires minimal configuration, unlike third-party modules that often demand additional software adjustments.

YPK112A

6. Selection Recommendations

- System Compatibility: Ensure your control system supports the communication protocols of the YPK112A (e.g., Profibus DP or Modbus RTU) and has compatible software for configuration.

- Environmental Fitness: If your application involves extreme temperatures or high electromagnetic interference, the YPK112A’s robust design makes it a preferable choice over modules with narrower operational limits.

- Signal Requirements: Verify that the module’s input types (4–20mA/0–10V) and resolution match the specifications of your field sensors to avoid compatibility issues.

- Scalability: For systems requiring future expansion, pair the YPK112A with ABB’s digital I/O modules (e.g., YDI131A or YDO132A) to create a comprehensive automation solution.

7. Precautions

- Installation: Always disconnect power before installing or replacing the module to prevent electrostatic discharge (ESD) damage. Use anti-static wrist straps and follow ABB’s grounding guidelines to minimize EMI.

- Cable Management: Use shielded twisted-pair cables for analog signal connections to reduce noise interference. Avoid routing signal cables alongside high-voltage power cables.

- Firmware Updates: Regularly update the module’s firmware using ABB’s official software (e.g., Automation Builder) to access the latest features and security patches.

- Calibration: Periodically calibrate the YPK112A using a certified signal source to ensure measurement accuracy, especially in applications with strict quality control requirements.

- Spare Parts Storage: Store unused modules in their original packaging at temperatures between -40°C and +85°C, away from moisture and direct sunlight.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.