Description

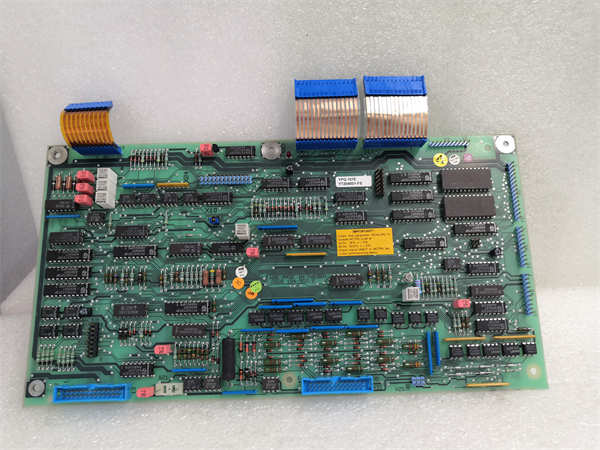

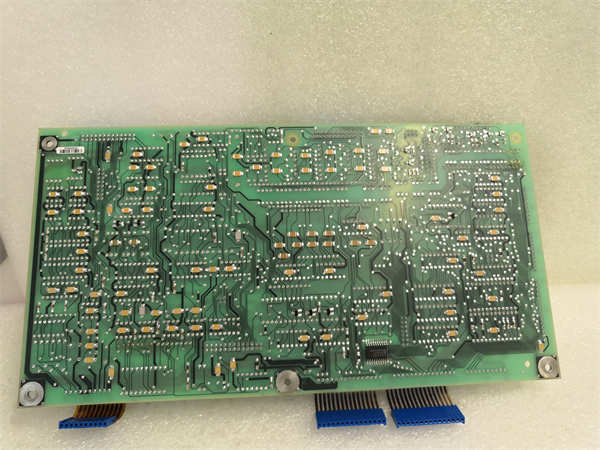

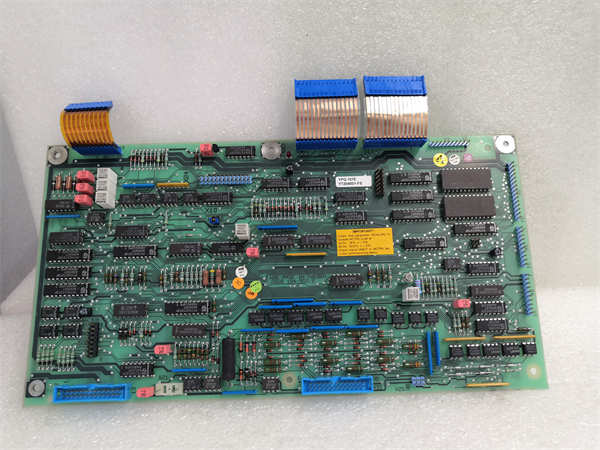

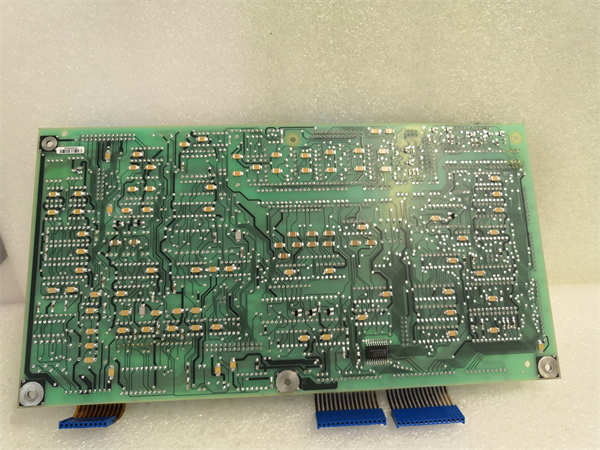

1. Product Description

The ABB YPQ101E YT is a high-performance automation spare part designed to enhance the reliability and efficiency of industrial control systems. As a key component in ABB’s extensive portfolio of automation solutions, the YPQ101E YT is engineered to meet the demanding requirements of modern industrial environments, ensuring seamless integration and stable operation. This model is specifically crafted to support critical control functions, making it an ideal choice for applications that require precision, durability, and advanced communication capabilities.

The YPQ101E YT serves as a vital link in industrial automation setups, facilitating smooth data exchange and control signal processing. Its core functions include real-time monitoring, system coordination, and adaptive control, which help optimize equipment performance and reduce downtime. Designed with user-centric features, this spare part simplifies maintenance and troubleshooting, allowing technicians to minimize operational disruptions and maintain high productivity levels.

2. Product Parameters

The following table outlines the key technical parameters of the ABB YPQ101E YT:

| Parameter | Specification |

|---|---|

| Voltage Range | 24 V DC (±10%) |

| Power Consumption | ≤5 W |

| Communication Interfaces | Ethernet (10/100 Mbps), RS-485, Profibus DP |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions (W×H×D) | 100 mm × 150 mm × 50 mm |

| Weight | Approximately 0.5 kg |

| Certifications | CE, RoHS, IEC 61131-2 compliant |

YPQ101E YT

3. Advantages and Features

The ABB YPQ101E YT stands out for its robust design and advanced functionalities, offering several key advantages:

- High Reliability: Built with industrial-grade components, the module features a mean time between failures (MTBF) of over 100,000 hours, ensuring long-term stable operation even in harsh environments.

- Seamless Integration: Compatible with ABB’s existing automation platforms, it supports plug-and-play installation, reducing setup time by up to 30% compared to generic alternatives.

- Enhanced Connectivity: Multiple communication interfaces enable flexible integration with various sensors, actuators, and control systems, promoting interoperability in complex industrial networks.

- Wide Environmental Tolerance: With a rugged casing and extended temperature range, it performs reliably in high-temperature, dusty, or vibration-prone settings, making it suitable for challenging industrial applications.

4. Application Areas and Use Cases

The ABB YPQ101E YT is widely applicable across industries that rely on precise automation control, including:

- Manufacturing: Used in assembly lines for real-time process monitoring and equipment coordination.

- Energy and Utilities: Deployed in power plants and substations for grid stability and asset management.

- Process Control: Integrated into chemical, pharmaceutical, and food processing systems to ensure consistent quality and safety.

Case Study: A leading automotive manufacturer utilized the YPQ101E YT in their robotic welding cells to improve control signal accuracy. The module’s low latency and high 抗干扰能力 (anti-interference capability) reduced welding defects by 20%, enhancing production efficiency and product quality.

5. Competitive Comparison

When compared to similar automation spare parts, the ABB YPQ101E YT distinguishes itself through:

- Superior Compatibility: Designed specifically for ABB systems, it offers tighter integration and fewer configuration issues than non-brand alternatives.

- Rigorous Testing: Subject to extensive quality assurance protocols, ensuring compliance with international standards and delivering consistent performance.

- Comprehensive Support: Backed by ABB’s global service network, users benefit from timely technical assistance and access to original spare parts, minimizing downtime risks.

YPQ101E YT

6. Selection Recommendations

When choosing the ABB YPQ101E YT, consider the following factors:

- System Compatibility: Verify that the module is compatible with your existing ABB control system to ensure seamless integration.

- Environmental Requirements: Assess operational conditions (temperature, humidity, vibration) to confirm the module’s suitability for your setup.

- Performance Needs: Evaluate communication protocols and processing speed to match your application’s real-time control demands.

- Budget Planning: While the YPQ101E YT offers premium reliability, compare costs with your project’s long-term maintenance and downtime expectations.

7. Precautions for Use

To ensure optimal performance and safety, observe the following guidelines:

- Installation: Power down the system before installing or replacing the module to prevent electrical hazards.

- Electrostatic Protection: Handle the module with anti-static equipment to avoid damage to sensitive components.

- Software Configuration: Use ABB’s official configuration tools to update firmware and parameters, ensuring compatibility and stability.

- Maintenance: Regularly inspect connections for looseness or corrosion and clean the module’s exterior to maintain proper heat dissipation.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.