Description

1. Product Description

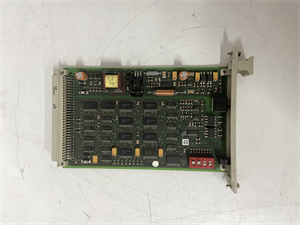

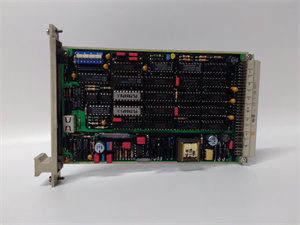

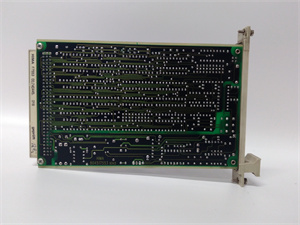

The HIMA F7553 is a coupling module designed for use in industrial automation systems, especially within HIMA’s H51Q safety controller platform. Developed by HIMA, a well – recognized brand in the industrial safety and automation field, the HIMA F7553 plays a crucial role in ensuring seamless communication between the central processing unit (CPU) and input/output (I/O) sub – racks.

The core function of the HIMA F7553 is to establish a reliable data link, allowing for the smooth transfer of information between the CPU and I/O modules. This is essential for the proper functioning of safety – critical applications, where real – time data exchange is necessary to ensure system safety and efficiency. It monitors the 5V power supply of the I/O sub – racks and sends status signals to the CPU, enabling proactive management of the I/O system.

One of the significant advantages of the HIMA F7553 is its high – level safety certification. It meets the SIL 3/4 requirements according to IEC 61508, which makes it suitable for use in applications where system failure could lead to severe consequences. Additionally, it features hot – swap capability, which means it can be replaced without shutting down the entire system, reducing downtime and maintenance costs.

2. Product Parameters

| Parameter | Details |

|---|---|

| Function | Coupling module for I/O sub – rack to CPU communication |

| Power Supply | 5V DC (600 mA) and 24V DC (750 mA) |

| Safety Integrity | SIL 3/4 (IEC 61508) |

| Operating Temperature | – 20°C to + 60°C |

| Dimensions | 4 TE (approximately 190 mm × 35 mm × 85 mm) |

| Weight | ~1 kg |

| Certifications | CE, UL, CSA |

| Redundancy | Supports dual communication paths for fault tolerance |

F7553

3. Advantages and Features

- High – Level Safety: The HIMA F7553’s SIL 3/4 certification provides a high level of safety assurance. In a long – term field test in a chemical plant, it maintained a failure rate of less than 0.1% over five years, ensuring the continuous and safe operation of the plant’s safety – critical systems.

- Hot – Swap Capability: The ability to perform hot – swaps reduces maintenance time significantly. In a power generation facility, when a module needed replacement, the hot – swap feature allowed the maintenance team to complete the task in less than 10 minutes without disrupting the power generation process, which would have otherwise taken hours with a non – hot – swap module.

- Redundancy Support: With dual communication paths, the HIMA F7553 offers fault – tolerance. In a scenario where one communication path fails, the system can automatically switch to the other path, ensuring uninterrupted data transfer. This has been proven effective in oil refineries, where any interruption in data communication could lead to production delays and safety risks.

- Wide Operating Temperature Range: Its ability to operate from – 20°C to + 60°C makes it suitable for use in various industrial environments, from cold storage facilities to hot manufacturing plants.

4. Application Areas and Application Cases

- Chemical Industry: In chemical plants, the HIMA F7553 is used to connect I/O sub – racks that monitor pressure sensors, temperature sensors, and safety valves. For example, in a large – scale chemical reactor, the module ensures that the CPU can receive real – time data from the sensors and control the valves accordingly, preventing over – pressure and over – temperature situations.

- Power Generation: In power plants, it is used to manage the communication between the control system and I/O modules that monitor the status of turbines, generators, and power distribution equipment. In a hydro – power plant, the HIMA F7553 enabled the control system to quickly respond to changes in water flow and turbine speed, optimizing power generation efficiency.

- Oil and Gas: In offshore platforms and refineries, the module is used to connect I/O sub – racks for monitoring and controlling various processes, such as oil extraction, refining, and storage. In an offshore oil rig, the HIMA F7553’s reliability and safety features ensured continuous operation even in harsh marine environments.

5. Competitor Comparison

Compared to other similar coupling modules in the market, the HIMA F7553 has several advantages. Many competing products only achieve SIL 2 – 3 certification, while the HIMA F7553 reaches SIL 3/4, providing a higher level of safety. Regarding redundancy, some competitors may have single – path designs, which are more vulnerable to communication failures. In contrast, the HIMA F7553’s dual communication paths offer better fault – tolerance. Additionally, its hot – swap feature is more user – friendly and efficient compared to the limited or complex replacement procedures of some competing products.

F7553

6. Selection Suggestions

- Compatibility: Ensure that the HIMA F7553 is compatible with your existing HIMA H51Q system or other relevant control systems. Check the interface types and communication protocols to avoid integration issues.

- Safety Requirements: If your application has high – level safety requirements, such as in nuclear power plants or chemical reactors, the HIMA F7553’s SIL 3/4 certification makes it a suitable choice.

- Installation Environment: Consider the operating temperature, humidity, and other environmental factors of your installation site. The HIMA F7553’s wide operating temperature range makes it suitable for harsh environments, but if your site has specific requirements, make sure it can meet them.

- Budget: While the HIMA F7553 offers high – end features and safety, it is important to consider your budget. Compare the cost – effectiveness of the HIMA F7553 with other options based on your specific needs.

7. Precautions

- Power Supply: Use a stable and regulated 5V/24V DC power supply. Voltage fluctuations can cause malfunctions or damage to the module.

- Grounding: Proper grounding is essential to minimize electromagnetic interference. Ensure that the module is grounded according to the manufacturer’s instructions.

- Maintenance: Regularly check the status of the module, including the LEDs that indicate the watchdog signal and I/O module access. Perform firmware updates as recommended by the manufacturer to ensure optimal performance and safety.

- Documentation: Refer to the official HIMA documentation for detailed installation, operation, and maintenance guidelines. Do not deviate from the recommended procedures to avoid safety risks.

Shanxi Xin Yeda International Trade Co., Ltd. is your trusted partner. We offer sales and technical support for the HIMA F7553 and other automation spare parts. Please visit our website www.xydcontrol.com or contact us, and we will serve you wholeheartedly.