Description

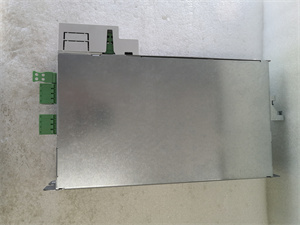

1. Product Description

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model | HCS02.1E-W0028-A-03-NNNN |

| Input Voltage | 3-phase AC 200–240V (+10%, -15%), 50/60Hz |

| Output Current (RMS) | 28A continuous, 42A peak (30s) |

| Control Modes | Torque, speed, position (via external pulses or fieldbus) |

| Communication Interfaces | CANopen, Profibus DP, EtherCAT (optional) |

| Motor Compatibility | Synchronous servo motors, induction motors |

| Protection Features | Overvoltage, overcurrent, overheating, short-circuit protection |

| Operating Temperature | 0–40°C (with derating up to 50°C) |

| Dimensions (WxHxD) | 120 x 220 x 170 mm |

| Weight | 3.5 kg |

HCS02.1E-W0028-A-03-NNNN

3. Advantages and Features

4. Application Areas and Case Study

5. Competitive Comparison

Compared to similar servo drives in the market, the HCS02.1E-W0028-A-03-NNNN offers a superior balance of performance and cost. It features a higher power density, allowing more power to be packed into a smaller form factor, which is particularly advantageous for space-constrained applications. The drive’s extensive range of communication options and motor compatibility surpasses many alternatives, ensuring flexibility across diverse system setups. Its robust protection features and wide operating temperature range also make it a more reliable choice for harsh industrial environments.

HCS02.1E-W0028-A-03-NNNN

6. Selection Recommendations

- Motor Compatibility: Ensure the drive’s output current and voltage ratings match your motor’s specifications.

- Control Network: Verify that the drive supports the communication protocol used in your system (e.g., EtherCAT, Profibus).

- Environmental Conditions: Check the operating temperature and humidity range to ensure suitability for your installation environment.

- Power Requirements: Confirm the input voltage matches your facility’s power supply to avoid compatibility issues.

- Performance Needs: Evaluate whether the drive’s control modes (torque, speed, position) align with your application’s precision and dynamic response requirements.

7. Precautions

- Installation: Always disconnect power before installing or servicing the drive to prevent electric shock. Ensure proper grounding to reduce electromagnetic interference (EMI).

- Cooling: Maintain adequate ventilation around the drive to prevent overheating, especially in high-temperature environments.

- Parameter Setup: Calibrate motor parameters accurately during commissioning to avoid performance issues or damage to the drive or motor.

- Maintenance: Regularly inspect connectors for loose connections and clean dust or debris from the drive’s vents to ensure optimal heat dissipation.

- Safety Compliance: Integrate the drive with appropriate safety devices (e.g., emergency stops) to meet industrial safety standards.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.