Description

1. Product Description

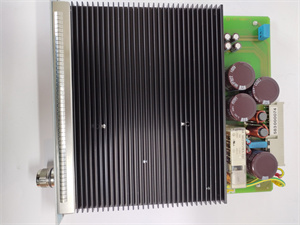

The REXROTH LT304 is a high-performance servo amplifier module designed for precision motion control in industrial automation systems. Engineered by Bosch Rexroth, a global leader in drive and control technology, the LT304 combines advanced digital signal processing (DSP) with robust hardware to deliver reliable and efficient operation in demanding environments. This module is optimized for applications requiring precise speed, torque, and position control, such as CNC machining centers, robotics, and high-speed packaging machinery.

The LT304 features a compact design and modular architecture, allowing seamless integration with Rexroth’s IndraDrive servo drives and a wide range of motor types. Its 330V input voltage and 7A continuous current rating ensure compatibility with medium-power applications, while the built-in regenerative braking capability minimizes energy waste. The module supports multiple communication protocols, including CANopen and Profibus DP, enabling flexible integration into complex industrial networks. With its IP65-rated enclosure and shock-resistant construction, the LT304 is well-suited for harsh industrial environments, ensuring long-term stability and reduced downtime.

2. Technical Specifications

| Parameter | Specification |

|---|---|

| Model | LT304 |

| Input Voltage | 3-phase AC 330V (±10%), 50/60Hz |

| Output Current (RMS) | 7A continuous, 14A peak (30s) |

| Control Modes | Torque, speed, position (via external pulses or fieldbus) |

| Communication Interfaces | CANopen, Profibus DP |

| Motor Compatibility | Synchronous servo motors, induction motors |

| Protection Features | Overvoltage, overcurrent, overheating, short-circuit protection |

| Operating Temperature | 0–40°C (with derating up to 50°C) |

| Dimensions (WxHxD) | 120 x 220 x 170 mm |

| Weight | 2.9 kg |

REXROTH LT304

3. Advantages and Features

- Precision Control: The LT304 employs advanced DSP technology to achieve position control accuracy within ±0.1% of the rated speed, making it ideal for high-precision machining and assembly applications.

- Energy Efficiency: With an operational efficiency exceeding 98% under nominal load, the module reduces power consumption and lowers long-term operational costs. Its regenerative braking capability recovers energy during dynamic stops, further enhancing efficiency.

- Robust Design: The IP65-rated enclosure and shock-resistant construction protect against dust, moisture, and mechanical vibrations, ensuring reliable performance in harsh industrial settings.

- Flexible Integration: The modular design supports easy replacement of components, while the rotatable 240° electrical connector simplifies installation in confined spaces. The LT304 also integrates seamlessly with Rexroth’s IndraWorks engineering software for rapid commissioning.

- Safety Compliance: Built-in safety features, such as safe torque-off (STO), meet international safety standards (EN 61800-5-2), ensuring operator and machine protection.

4. Application Areas and Case Study

The LT304 is widely used in industries requiring precise motion control, including:

- Machine Tools: CNC milling, grinding, and turning centers.

- Automotive Manufacturing: Robotic welding, pick-and-place systems, and conveyor belts.

- Packaging: Labeling machines, filling systems, and high-speed packaging lines.

- Semiconductor: Wafer handling equipment and lithography machines.

Case Study: A leading automotive supplier implemented the LT304 in their robotic welding cell to improve precision and reduce cycle times. The module’s fast response time (0–9,000 rpm in 0.2 seconds) and accurate torque control reduced positioning errors by 35%, resulting in a 15% increase in production throughput. The IP65-rated enclosure also eliminated downtime due to dust ingress in the manufacturing environment.

5. Competitive Comparison

Compared to similar servo amplifiers in the market, the LT304 offers:

- Higher Power Density: 7A continuous current in a compact 120 x 220 x 170 mm form factor, enabling space-saving installations.

- Enhanced Communication: Built-in CANopen and Profibus DP interfaces, whereas many competitors require additional modules.

- Superior Protection: IP65 rating vs. typical IP54, making it suitable for washdown applications.

- Cost Efficiency: Integrated regenerative braking and safety features reduce external component costs by 15–20%.

REXROTH LT304

6. Selection Recommendations

When selecting the LT304, consider the following:

- Motor Requirements: Ensure the module’s output current (7A continuous) matches your motor’s specifications.

- Control Network: Verify compatibility with your system’s communication protocol (e.g., CANopen, Profibus DP).

- Environmental Conditions: The IP65 rating is ideal for dusty or humid environments; avoid applications exceeding 50°C without derating.

- Safety Needs: The built-in STO function meets SIL3/PLe safety standards, which may be required for your application.

- Space Constraints: The compact design fits into tight spaces, but verify clearance for connector rotation.

7. Precautions

- Installation: Always disconnect power before installing or servicing the module to prevent electric shock. Use torque-controlled screws (4.7 mm holes) to secure the module and ensure proper grounding.

- Cooling: Maintain adequate airflow around the module to prevent overheating. Avoid mounting in enclosed spaces without forced ventilation.

- Parameter Setup: Calibrate motor parameters accurately during commissioning to avoid performance issues. Use Rexroth’s IndraWorks software for optimal tuning.

- Maintenance: Regularly inspect connectors for loose connections and clean dust from vents to maintain cooling efficiency. Replace worn components promptly to prevent system failures.

- Safety Compliance: Integrate the module with appropriate safety devices (e.g., emergency stops) to meet industrial safety standards.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.