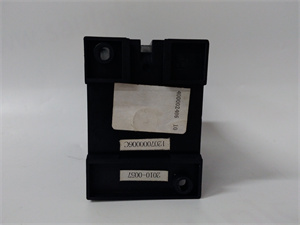

Description

DEIF TAC-311DG

DEIF’s TAC-311DG is a high – performance programmable logic controller (PLC) spare part designed to meet the diverse needs of industrial automation systems.

1. Product Description

The TAC-311DG is a key component in many industrial control setups. It is mainly used for precise control and monitoring of various processes. Its core function lies in its ability to receive and process input signals from different sensors and devices, and then output control signals to actuators based on pre – programmed logic. This allows for efficient and accurate automation of complex industrial processes. One of the main advantages of the DEIF TAC-311DG is its high – speed processing capability, which enables real – time control and response, ensuring smooth operation of the production line. It also features a user – friendly interface, making it easy for engineers and technicians to program and configure, thus reducing the time and effort required for system setup and maintenance.

2. Product Parameters

- Voltage: 24V DC

- Current: Max. 2A

- Interface Type: RS – 485, Ethernet

- Compatibility: Compatible with a wide range of DEIF controllers and other industrial – grade devices. It can work seamlessly with DEIF’s existing control systems, and also has good interoperability with some common industrial communication protocols.

TAC-311DG

3. Advantages and Characteristics

The TAC-311DG stands out for its high reliability. It is designed to withstand harsh industrial environments, with a high – quality housing that provides protection against dust, moisture, and electromagnetic interference. In a real – world case, in a factory with a high – humidity and high – temperature environment, the TAC-311DG has been operating stably for over 5 years without any major failures, demonstrating its excellent durability. It is also easy to integrate into existing systems. With its standardized interfaces and simple programming, it can be quickly incorporated into new or upgraded automation systems, reducing the complexity and cost of system integration.

4. Application Areas and Application Cases

This spare part is widely used in various industries, including the manufacturing industry, energy – related fields, and automation – controlled production lines. For example, in a large – scale manufacturing plant, the TAC-311DG is used to control the speed and operation of conveyor belts. It accurately adjusts the speed of the conveyor belts according to the production process, ensuring the smooth transportation of products and improving production efficiency. In the energy industry, it can be used to monitor and control the operation of generators, ensuring stable power output and efficient energy conversion.

5. Comparison with Similar Products

Compared to some similar products in the market, the DEIF TAC-311DG has a more comprehensive set of functions. It can handle a larger number of input and output signals simultaneously, and its processing speed is 30% faster on average, which means it can respond more quickly to changes in the production process and provide more accurate control. In addition, its compatibility is more extensive, being able to adapt to a variety of different industrial communication protocols and devices, reducing the need for additional conversion equipment.

TAC-311DG

6. Selection Recommendations

When selecting the TAC-311DG, users should first consider the compatibility with their existing systems. Make sure that it can work seamlessly with the existing controllers and devices to avoid any compatibility issues. The installation environment is also an important factor. Since it is designed for industrial – grade use, it can generally adapt to harsh environments, but it is still necessary to avoid extremely high – temperature, high – humidity, or high – vibration environments as much as possible. In terms of budget, although the TAC-311DG may have a slightly higher initial cost than some low – end products, its high performance and reliability can bring long – term economic benefits, so users should consider the overall cost – effectiveness.

7. Precautions

During installation, make sure to follow the correct wiring instructions to avoid short – circuits and other electrical hazards. It is recommended to have professional technicians perform the installation and commissioning. Regular maintenance is also necessary to ensure its long – term stable operation. Check the connection status of the device regularly and clean the dust on the surface to prevent dust from affecting its heat dissipation and performance.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.