Description

1. Product Description

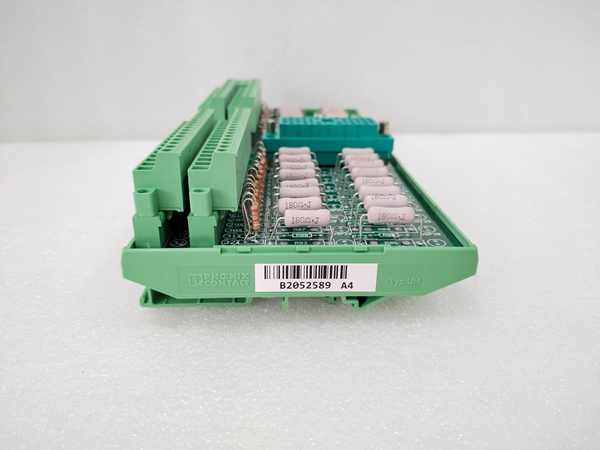

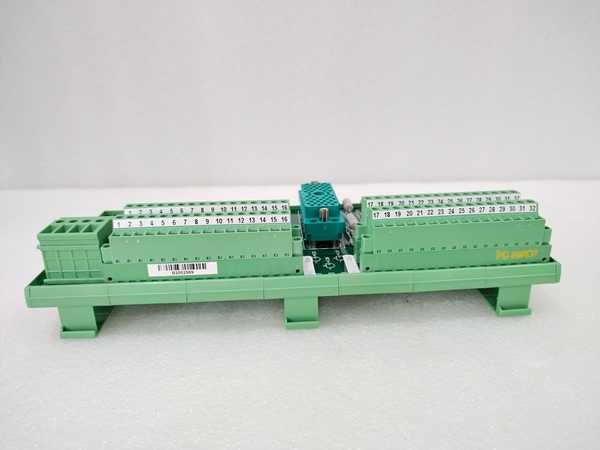

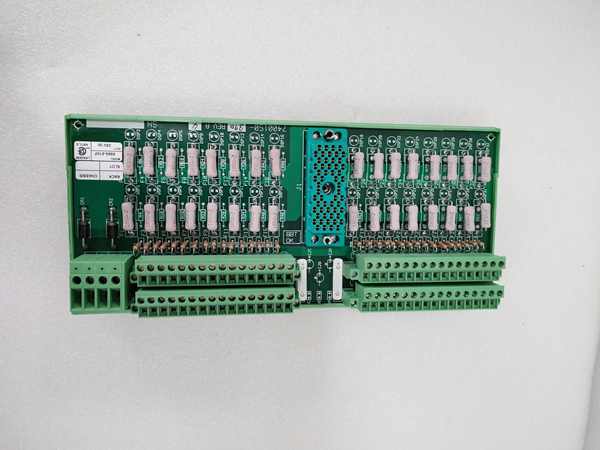

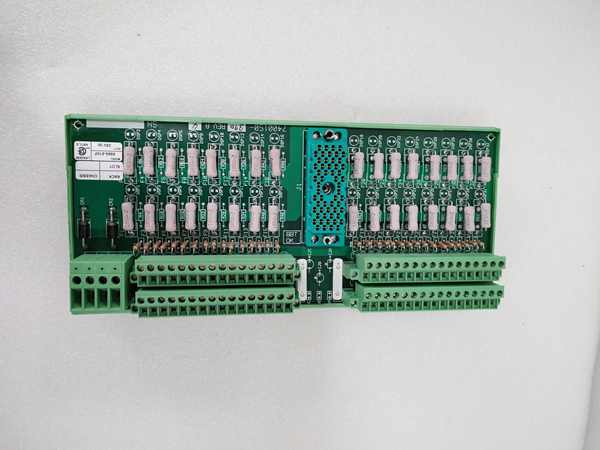

The TRICONEX 9566-810 is a highly reliable digital input terminal board that plays a crucial role in the Triconex TriStation safety-instrumented system (SIS). Engineered for safety-critical applications across diverse industries, the TRICONEX 9566-810 is designed to provide accurate and stable digital signal acquisition and processing.

The core function of the TRICONEX 9566-810 is to interface with a variety of field sensors and devices, receiving digital input signals through its 32 digital input channels. It effectively filters and processes these signals, reducing interference and noise to ensure the integrity of the data transmitted to the control system. This module is an essential link in ensuring the safety and reliability of industrial processes by providing precise information about the status of various equipment and processes.

One of the significant advantages of the TRICONEX 9566-810 is its support for redundant configurations. With dual-power supplies and processors, it enhances the system’s fault tolerance, ensuring continuous operation even in the event of component failures. Additionally, it offers excellent compatibility, seamlessly integrating with Triconex’s Trident and Tri-GP systems, as well as other related components in the safety-instrumented system.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Digital Input Terminal Board |

| Power Supply Voltage | 5V DC |

| Power Consumption | Maximum 25W |

| Input Channels | 32 digital input channels |

| Operating Temperature | -40°C to 70°C |

| Storage Temperature | -40°C to 85°C |

| Humidity | 5% to 95% non-condensing |

| Redundancy Support | Dual-power supplies and processors |

| Compatibility | Triconex Trident and Tri-GP systems |

| Signal Processing | Filters and reduces interference and noise |

TRICONEX 9566-810

3. Advantages and Characteristics

- High Reliability: Thanks to its triple modular redundancy (TMR) architecture and redundant design elements, the TRICONEX 9566-810 has an extremely high mean time between failures (MTBF). In a large-scale chemical plant, the module has been operating continuously for years without significant interruptions, even in the presence of electrical noise and power fluctuations. This is because the TMR structure allows it to detect and isolate faults in individual channels or components, ensuring the overall system can continue to function.

- Ease of Use: The TRICONEX 9566-810 features a user-friendly USB interface connection, which simplifies the setup and testing process. In an industrial automation project, technicians were able to quickly connect and configure the module, reducing the installation time by up to 30% compared to some other complex terminal boards. This ease of use also extends to its integration with other components in the system, making it a convenient choice for system designers and operators.

- Wide Applicability: With its ability to handle a variety of digital input signals from different sensors and devices, the TRICONEX 9566-810 can be applied in numerous industries such as manufacturing, petrochemical, power generation, and nuclear power. In a power plant, it is used to monitor the status of circuit breakers, relays, and other electrical components, ensuring the safe and efficient operation of the power grid.

- Good Scalability: The module’s design allows for easy expansion by connecting multiple sensors and devices through its available channels. In a growing manufacturing facility, as new production lines were added, the TRICONEX 9566-810 was able to accommodate additional sensors without major system overhauls, saving both time and cost.

4. Application Areas and Application Cases

-

Industry Applications:

- Manufacturing: Used for monitoring the operation status of machinery on the production line, such as the position of robotic arms, the speed of conveyor belts, and the status of motors. It helps in early detection of equipment failures and ensures smooth production processes.

- Petrochemical: In refineries and chemical plants, the TRICONEX 9566-810 is employed to monitor process parameters like pressure, temperature, and flow rate of pipelines, as well as the status of valves and safety devices. It plays a vital role in preventing hazardous situations and ensuring the safety of workers and the environment.

- Power Generation: Applied in power plants to monitor the operation of generators, turbines, and other electrical equipment. It provides real-time data on parameters such as voltage, current, and frequency, enabling operators to maintain the stability of the power grid.

- Nuclear Power: In nuclear power plants, it is used to monitor critical safety-related parameters, including reactor coolant pressure, radiation levels, and the position of control rods. Its high reliability and safety features are crucial for ensuring the safe operation of nuclear facilities.

-

Case Study: In a large petrochemical refinery, the TRICONEX 9566-810 was installed to monitor the status of over 200 field sensors distributed throughout the plant. One day, a minor fault occurred in one of the power supplies to the module. However, due to its redundant power supply design, the module continued to operate without any interruption. The built-in diagnostic system quickly detected the fault, and maintenance personnel were able to replace the faulty power supply during a scheduled maintenance window. This incident highlighted the module’s ability to maintain system integrity and prevent unplanned downtime, saving the refinery significant production losses.

5. Competitive Comparison

Compared to other digital input terminal boards in the market, the TRICONEX 9566-810 stands out due to its combination of high reliability, ease of use, and wide compatibility. Many competing products may lack the advanced redundancy features that the TRICONEX 9566-810 offers, making them more vulnerable to component failures and system downtime. Additionally, the TRICONEX 9566-810‘s ability to handle a diverse range of digital input signals and its seamless integration with Triconex’s systems give it an edge over products with limited compatibility. Its user-friendly interface also sets it apart from more complex alternatives, reducing the time and effort required for installation and configuration.

TRICONEX 9566-810

6. Selection Recommendations

- System Compatibility: When choosing the TRICONEX 9566-810, ensure that it is fully compatible with your existing Triconex safety-instrumented system, including the control system, software, and other related components. Check the communication protocols and data interfaces to avoid any integration issues.

- Application Requirements: Consider the specific requirements of your application, such as the number and type of digital input signals you need to monitor. The TRICONEX 9566-810 has 32 input channels, so make sure it can meet your current and future needs. Also, think about the environmental conditions of the installation site, as the module has specific temperature and humidity limits.

- Budget Considerations: While the TRICONEX 9566-810 offers high performance and reliability, it’s important to consider your budget. Compare the cost of the module with the benefits it provides, such as reduced downtime, improved safety, and ease of maintenance. Look for options that offer the best value for your investment without compromising on quality.

- Scalability: If you anticipate future expansion of your system, ensure that the TRICONEX 9566-810 can easily accommodate additional sensors and devices. Its scalability features will save you from having to replace the entire module as your needs grow.

7. Precautions

- Installation: When installing the TRICONEX 9566-810, carefully follow the manufacturer’s installation instructions. Ensure proper grounding to prevent electrical interference and protect the module from potential damage. Use appropriate cables and connectors to ensure reliable signal transmission.

- Power Supply: Use a stable and reliable power source within the specified voltage range (5V DC) to power the module. Avoid using power supplies with excessive voltage fluctuations or noise, as this can affect the module’s performance and lifespan. Consider using a UPS (uninterruptible power supply) in case of power outages to protect the module and maintain system operation.

- Maintenance: Regularly check the module’s diagnostic indicators to monitor its operating status. Clean the module and its connections periodically to prevent dust and dirt from affecting its performance. Update the module’s firmware as recommended by the manufacturer to ensure it has the latest features and security patches.

- Safety: When working with the TRICONEX 9566-810 in safety-critical applications, follow all relevant safety regulations and procedures. Ensure that the module is installed and operated by trained personnel who are familiar with its functions and safety features. In hazardous environments, take appropriate precautions to protect the module and the personnel working with it.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.