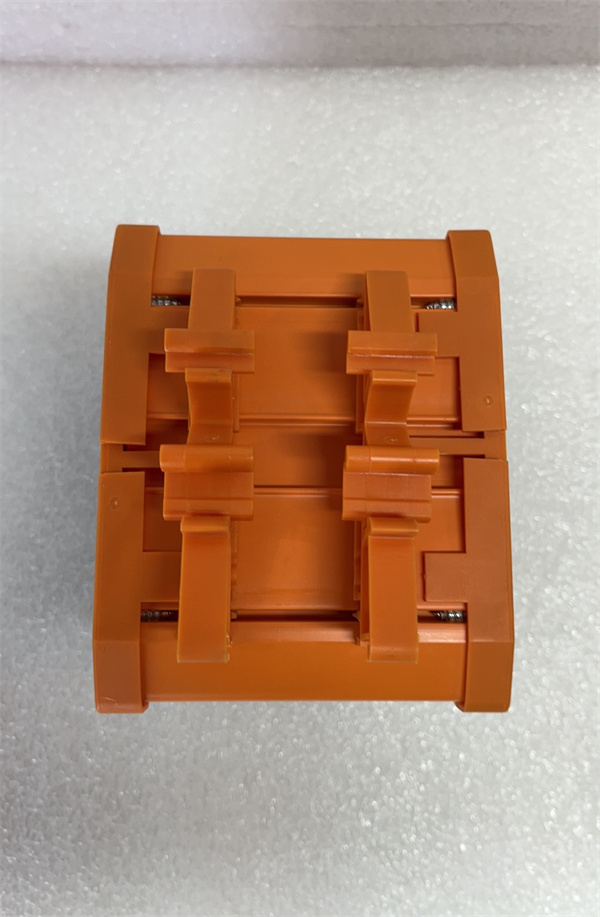

Description

1. Product Description

2. Product Parameters

| Parameter | Specification |

|---|---|

| Model | VT-MACAS-500-10/V0/I |

| Brand | REXROTH |

| Type | Hydraulic Control Module |

| Input Voltage | 24 VDC ±10% |

| Power Consumption | ≤5 W |

| Input Signals | Analog (0-10 V, 4-20 mA) / Digital (TTL) |

| Output Signals | Analog (0-10 V, 4-20 mA) |

| Communication Interface | RS-485 (Modbus RTU) |

| Control Accuracy | ±0.5% of full scale |

| Operating Temperature | -20°C to +60°C |

| Protection Class | IP20 (indoor use) |

| Weight | 0.8 kg |

VT-MACAS-500-10/V0/I

3. Advantages and Features

- High Precision Control: Achieves ±0.5% accuracy in signal conversion, critical for applications requiring tight hydraulic control, such as CNC machines or robotic arms.

- Flexible I/O Configuration: Supports multiple analog and digital signal formats, reducing the need for additional converters and simplifying system integration.

- Robust Error Handling: Includes built-in diagnostic functions that monitor voltage levels, temperature, and signal integrity, providing early warnings for potential issues and minimizing downtime.

- Wide Operating Range: Functions reliably across a broad temperature spectrum (-20°C to +60°C), making it suitable for both indoor and outdoor industrial environments.

4. Application Areas and Case Study

- Manufacturing: CNC machining centers, press systems, and assembly lines.

- Energy: Hydraulic power units in wind turbines and industrial pumps.

- Construction Machinery: Excavators, loaders, and material handling equipment.

5. Competitive Comparison

When compared to similar hydraulic control modules on the market, the REXROTH VT-MACAS-500-10/V0/I distinguishes itself through its superior accuracy, flexible signal compatibility, and robust diagnostic capabilities. Unlike some alternatives, it offers a wider temperature tolerance and easier integration with REXROTH’s comprehensive motion control ecosystem, ensuring seamless compatibility with existing hardware and software. Its balanced combination of performance, durability, and cost-effectiveness makes it a preferred choice for both retrofitting older systems and designing new automation setups.

VT-MACAS-500-10/V0/I

6. Selection Recommendations

- Compatibility: Ensure the module’s input/output signals match your control system’s requirements (e.g., analog vs. digital, voltage/current ranges).

- Environmental Conditions: Verify the operating temperature, humidity, and protection class to suit your installation environment (e.g., indoor vs. outdoor, high-dust areas).

- Control Precision Needs: If your application requires sub-1% accuracy for hydraulic positioning, this module’s ±0.5% precision makes it an excellent fit.

- System Integration: Prioritize compatibility with your existing automation architecture, especially if using REXROTH components, to leverage seamless communication and simplified programming.

7. Precautions

-

Electrical Safety: Disconnect power before installing or servicing the module to prevent electric shock or damage.

-

Cable Installation: Use shielded cables for signal connections to minimize electromagnetic interference (EMI), especially in high-power environments.

-

Calibration: Perform initial calibration using the manufacturer’s software to match your specific hydraulic system parameters.

-

Regular Maintenance: Periodically check for loose connections, temperature fluctuations, and software updates to maintain peak performance.

-

Environmental Protection: If used in dusty or humid environments, consider additional enclosures to meet IP65 or higher protection standards, even though the module itself is rated IP20.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.