Description

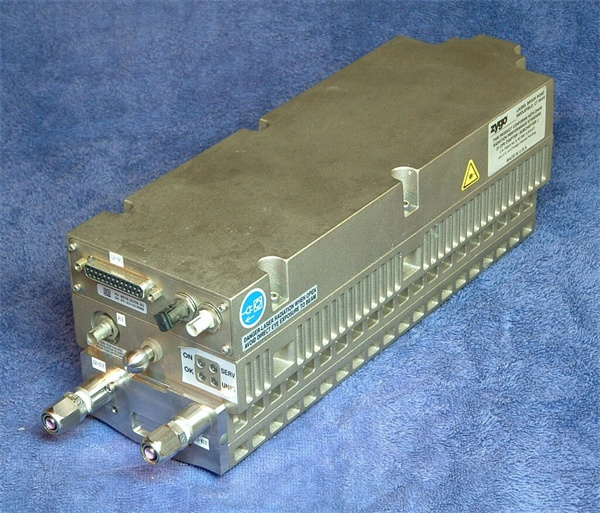

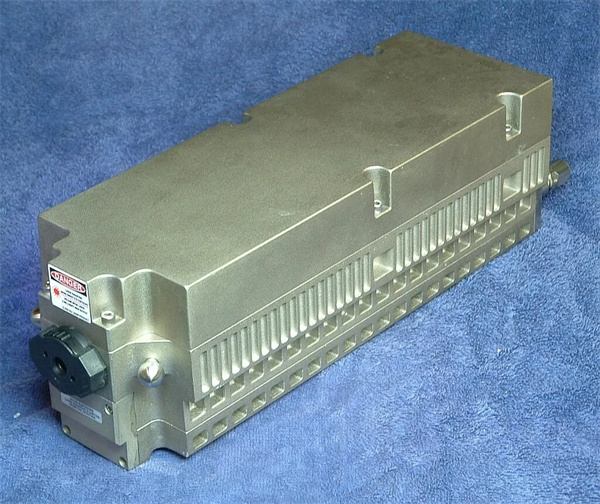

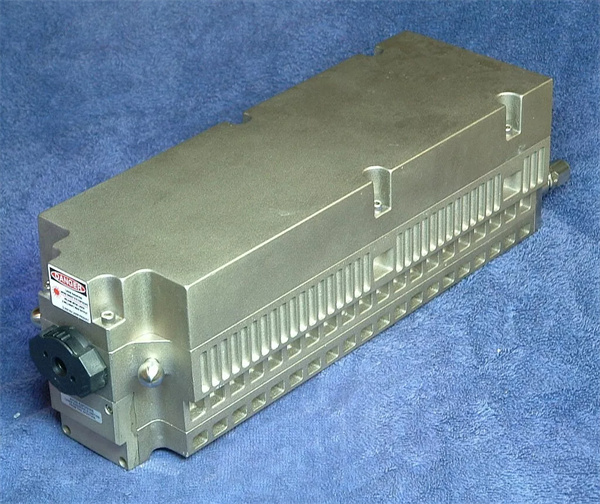

ZYGO 7712 is a highly specialized component designed for precision optical metrology systems, playing a crucial role in enabling accurate measurements in various industrial and research applications. It is a key part of ZYGO’s advanced measurement solutions, which are renowned for their high precision and reliability.

1. Product Description

The ZYGO 7712 is a high-performance laser module that is typically used in conjunction with ZYGO’s interferometric measurement systems. It emits a stable and precise laser beam, which serves as the basis for measuring the displacement, surface topography, and other critical parameters of optical components and mechanical structures. This module is engineered to provide exceptional accuracy, making it suitable for applications where even the slightest deviation can have a significant impact on the quality of the final product.

The 7712 is designed to integrate seamlessly with other components of ZYGO’s measurement systems, ensuring smooth operation and reliable data acquisition. Its compact size and robust construction make it suitable for use in a variety of environments, from cleanroom facilities in semiconductor manufacturing to harsh industrial settings. With its advanced technology, the ZYGO 7712 enables users to perform high-precision measurements with ease, improving the efficiency and quality of their processes.

One of the key features of the ZYGO 7712 is its ability to maintain a stable laser output over time. This stability is essential for achieving accurate and repeatable measurements, especially in long-term monitoring applications. Additionally, the module offers a wide range of adjustable parameters, allowing users to customize the laser output to meet the specific requirements of their applications.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Laser Type | Helium-Neon (HeNe) |

| Wavelength | 632.8 nm |

| Output Power | Typically in the range of 0.5 mW to 1 mW |

| Beam Diameter | Adjustable, usually between 3 mm and 6 mm |

| Frequency Stability | ±0.01 ppm over 24 hours |

| Beam Pointing Stability | < 0.1 arcsec/°C |

| Operating Temperature | 10°C to 30°C (non-condensing) |

| Power Supply | 100 – 240 VAC, 50/60 Hz |

| Interfaces | Standard optical and electrical interfaces for connection to measurement systems |

| Compatibility | Compatible with ZYGO’s range of interferometric measurement equipment |

ZYGO 7712

3. Advantages and Features

- High Precision: The ZYGO 7712 offers sub-nanometer resolution, allowing for extremely accurate measurements. In a semiconductor manufacturing application, it can be used to measure the thickness of thin films on wafers with an accuracy of within a few nanometers, ensuring the quality and performance of the final chips.

- Stability: With its excellent frequency and beam pointing stability, the module provides consistent and reliable measurement results over extended periods. This is demonstrated in long-term monitoring of large-scale optical mirrors in astronomical observatories, where the 7712 maintains its accuracy despite environmental fluctuations.

- Flexibility: The adjustable parameters of the ZYGO 7712 enable users to adapt the laser output to different measurement requirements. For example, in precision machining, the beam diameter can be adjusted to focus on specific areas of a workpiece, providing more detailed measurement data.

- Ease of Integration: The module is designed to integrate seamlessly with ZYGO’s measurement systems, reducing the complexity of installation and setup. This has been proven in numerous industrial applications where the 7712 has been quickly integrated into existing measurement setups, saving time and effort.

4. Application Areas and Application Cases

- Semiconductor Manufacturing: The ZYGO 7712 is widely used in semiconductor manufacturing for measuring the dimensions and surface quality of wafers, masks, and other components. In a leading semiconductor fabrication plant, the 7712 was used in an inspection system to detect defects on wafers at an early stage, reducing the production of defective chips and improving overall yield.

- Aerospace and Defense: In the aerospace and defense industries, the module is used for precision measurement of components such as aircraft wings, engine parts, and optical systems. For instance, in the manufacturing of high-precision optical lenses for military telescopes, the ZYGO 7712 ensured that the lenses met the strict quality standards required for accurate targeting.

- Precision Machining: The 7712 is also valuable in precision machining applications, where it is used to measure the accuracy of machined parts and to monitor the performance of machine tools. A precision machining company used the ZYGO 7712 to measure the flatness of a large metal plate, achieving a measurement accuracy that was crucial for the subsequent assembly of the final product.

5. Competitor Comparison

Compared to other laser modules in the market, the ZYGO 7712 stands out for its superior precision and stability. While some competing products may offer similar features, they often lack the level of accuracy and reliability provided by the 7712. The ZYGO 7712‘s ability to maintain a stable laser output over time and its high frequency stability make it a preferred choice for applications where precision is of utmost importance. Additionally, its compatibility with ZYGO’s comprehensive range of measurement systems provides a more integrated and efficient solution compared to some competitors that may require additional components or complex integration processes.

ZYGO 7712

6. Selection Recommendations

- Compatibility: When selecting the ZYGO 7712, ensure that it is compatible with your existing measurement system or the system you plan to use. Check the interfaces and specifications to ensure a seamless integration.

- Precision Requirements: Consider the level of precision required for your application. If your application demands sub-nanometer accuracy, the 7712 is a suitable choice. However, if lower precision is acceptable, you may explore other options that are more cost-effective.

- Environmental Conditions: Take into account the operating environment of the module. If it will be used in a harsh environment with extreme temperatures or high levels of vibration, ensure that the ZYGO 7712 can withstand these conditions.

- Budget: While the ZYGO 7712 offers high performance, it may come at a higher cost compared to some other modules. Evaluate your budget and determine if the benefits provided by the 7712 justify the investment for your specific application.

7. Precautions

- Installation: When installing the ZYGO 7712, follow the manufacturer’s instructions carefully. Ensure that all connections are secure and that the module is properly aligned to avoid any interference with the laser beam.

- Operation: During operation, avoid looking directly into the laser beam to prevent eye damage. Also, ensure that the module is not exposed to any sources of electromagnetic interference that could affect its performance.

- Maintenance: Regularly maintain the 7712 according to the recommended schedule. This may include cleaning the optical components, checking the alignment of the laser beam, and replacing any worn-out parts.

- Calibration: Periodically calibrate the module to ensure its accuracy. Use the calibration procedures provided by ZYGO to ensure that the ZYGO 7712 is performing at its best.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.