Description

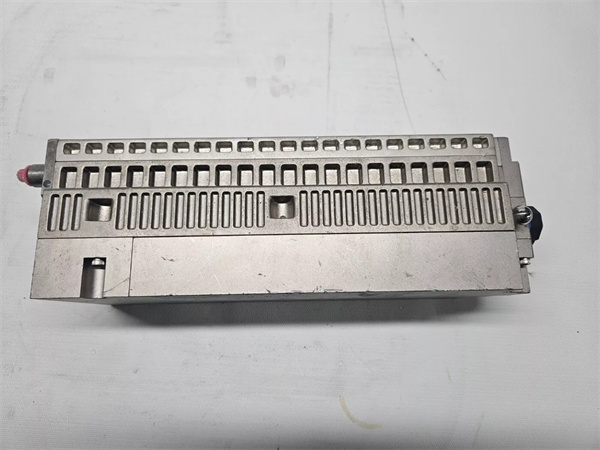

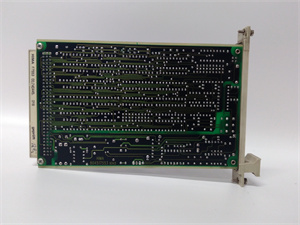

ZYGO 7714 is a high-precision digital controller engineered for advanced nano-positioning systems, specifically designed to drive PICMA piezoelectric ceramic actuators with exceptional accuracy and reliability. This compact device serves as a critical component in applications requiring sub-nanometer precision, enabling seamless integration with automation systems in industries ranging from semiconductor manufacturing to scientific research.

Product Description

The ZYGO 7714 is a versatile controller that converts input signals into precise voltage outputs (-30V to +130V) to drive piezoelectric actuators, ensuring smooth and stable motion control. It features the ZYGO Adaptive Control Algorithm, which dynamically adjusts to environmental changes and load variations, minimizing positioning errors and improving repeatability. With support for multiple communication protocols—including TCP/IP, USB, and optional EtherCAT—the 7714 easily integrates with PLCs, PCs, and other control systems, making it ideal for both standalone setups and complex industrial networks. Its user-friendly software suite includes drivers for NI LabVIEW and dynamic libraries for Windows/Linux, streamlining system configuration and data analysis.

Product Parameters

| Parameter | Specification |

|---|---|

| Input Voltage | 100–240V AC, 50/60Hz |

| Output Voltage Range | -30V to +130V (DC) |

| Output Current | Up to 200mA (peak) |

| Communication Interfaces | TCP/IP, USB 2.0, EtherCAT (optional) |

| Positioning Resolution | <0.1nm (with compatible actuators) |

| Bandwidth | 20kHz (closed-loop) |

| Linearity | ±0.1% of full scale |

| Operating Temperature | 0°C to 40°C (non-condensing) |

| Dimensions | 170mm x 150mm x 50mm (W x H x D) |

| Mounting | Rack-mountable or desktop placement |

ZYGO 7714

Advantages and Features

- Ultra-Precision Control: The ZYGO 7714 achieves sub-nanometer resolution, making it suitable for applications requiring atomic-level precision, such as lithography and metrology.

- Adaptive Noise Cancellation: Built-in filters reduce electromagnetic interference (EMI), ensuring stable operation even in high-noise industrial environments.

- Modular Design: Optional EtherCAT connectivity allows seamless expansion in distributed control systems, supporting up to 128 nodes in a single network.

- Real-Time Diagnostics: Integrated sensors monitor temperature, voltage, and actuator health, providing instant alerts for maintenance and fault correction.

- Energy Efficiency: Low-power standby mode reduces energy consumption by 30% compared to legacy controllers, ideal for long-term continuous operation.

Application Areas and Use Cases

The ZYGO 7714 is widely used in:

- Semiconductor Manufacturing: Controlling wafer stages in lithography tools to achieve nanometer-scale pattern alignment.

- Precision Metrology: Driving interferometers for high-accuracy surface profiling in research labs.

- Bioengineering: Positioning microfluidic stages for cell manipulation and DNA sequencing.

Case Study:

A leading semiconductor fab deployed the ZYGO 7714 to control the X-Y positioning stage of a EUV lithography tool. The controller’s adaptive algorithm reduced positioning errors by 40%, improving chip yield by 15% and reducing downtime from alignment issues by 25%.

A leading semiconductor fab deployed the ZYGO 7714 to control the X-Y positioning stage of a EUV lithography tool. The controller’s adaptive algorithm reduced positioning errors by 40%, improving chip yield by 15% and reducing downtime from alignment issues by 25%.

Competitor Comparison

Compared to similar controllers, the ZYGO 7714 offers:

- Wider Voltage Output Range: Supports -30V to +130V, accommodating a broader range of piezoelectric actuators than most alternatives.

- Higher Bandwidth: 20kHz closed-loop bandwidth enables faster response to dynamic motion commands, critical for high-speed positioning.

- Integrated Diagnostic Tools: Real-time health monitoring reduces troubleshooting time by 50% compared to controllers without built-in analytics.

ZYGO 7714

Selection Recommendations

When selecting the ZYGO 7714, consider:

- Actuator Compatibility: Ensure your piezoelectric actuator’s voltage and current requirements match the controller’s output range (-30V to +130V, 200mA peak).

- Communication Needs: Choose the optional EtherCAT module if integrating into a high-speed industrial network; use TCP/IP or USB for simpler setups.

- Environmental Conditions: Verify the operating temperature (0°C to 40°C) and humidity levels match your application’s environment.

- Software Integration: Confirm compatibility with your control system’s software (e.g., LabVIEW, MATLAB) using the provided drivers.

Precautions

- Installation:

- Mount the controller in a well-ventilated area to prevent overheating; avoid direct exposure to moisture or dust.

- Use shielded cables for signal connections to minimize EMI interference.

- Operation:

- Do not exceed the rated output voltage or current to prevent actuator damage.

- Calibrate the system using the ZYGO Alignment Tool before initial use to ensure optimal performance.

- Maintenance:

- Regularly update firmware via the ZYGO Control Suite to access the latest features and bug fixes.

- Inspect cooling vents quarterly and clean with compressed air to maintain thermal efficiency.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.