Description

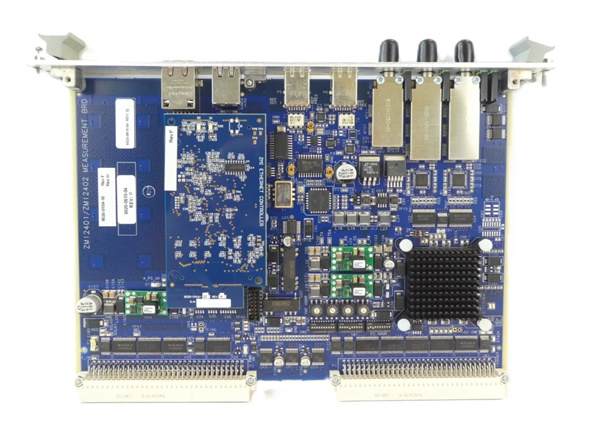

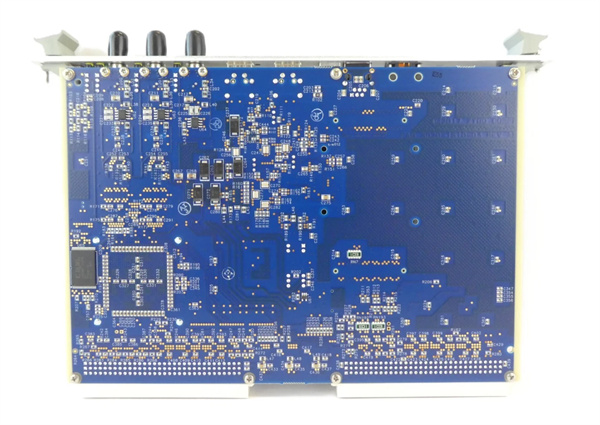

ZYGO 8020-0610-04 is a high-precision VMEbus interface module designed for advanced displacement measuring interferometer (DMI) systems, enabling seamless integration and real-time data processing in precision motion control applications. Engineered to meet the rigorous demands of industrial and research environments, this module serves as a critical component for achieving nanometer-level accuracy in displacement measurements, making it ideal for applications where precision is non-negotiable.

1. Product Description

The ZYGO 8020-0610-04 is a compact, ruggedized module that interfaces with ZYGO’s ZMI series interferometers to convert optical displacement data into digital signals for control systems. It supports dual-axis measurement, allowing simultaneous monitoring of two independent motion axes with sub-nanometer resolution. The module features a VMEbus interface, ensuring high-speed data transfer (up to 40 MB/s) and compatibility with standard industrial control platforms.

Designed for ease of integration, the 8020-0610-04 simplifies system setup by leveraging ZYGO’s proprietary software tools, which enable automatic calibration and real-time diagnostics. Its robust design withstands environmental fluctuations, including temperature variations and electromagnetic interference (EMI), ensuring stable performance in harsh manufacturing environments. Whether used in semiconductor wafer stages, precision machining tools, or aerospace component testing, the ZYGO 8020-0610-04 delivers reliable, high-speed displacement data to optimize process control and quality assurance.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Power Supply | 5V DC ±5% (VMEbus-derived), 12V DC ±10% (optional for analog signals) |

| Interface | 32-bit VMEbus (A24/D32), P2 differential I/O for interferometer connectivity |

| Displacement Resolution | 0.6 nm (with ZYGO’s dual-frequency HeNe lasers) |

| Measurement Speed | Up to 1.1 m/s (real-time velocity tracking) |

| Axes Supported | 2 independent axes |

| Bandwidth | 20 kHz (closed-loop control bandwidth) |

| Operating Temperature | 0°C to 40°C (non-condensing) |

| Dimensions | 233.4 mm x 160 mm x 25.4 mm (6U VME form factor) |

| Weight | 500 g |

| Compatibility | ZMI-1000, ZMI-1000A, and ZMI-2000 series interferometers; VMEbus-based controllers |

ZYGO 8020-0610-04

3. Advantages and Features

- Ultra-High Resolution: The 8020-0610-04 achieves a displacement resolution of 0.6 nm, enabling detection of minute motion errors critical for semiconductor lithography and precision metrology.

- Dual-Axis Capability: Supports simultaneous measurement of two axes, reducing system complexity by eliminating the need for separate modules and improving synchronization between motion axes.

- High-Speed Data Transfer: Utilizes VMEbus technology for fast data throughput (40 MB/s), ensuring real-time feedback control in high-speed motion systems.

- Robust Environmental Performance: Engineered to operate in temperatures from 0°C to 40°C and resist EMI, making it suitable for industrial floors with heavy machinery or high-frequency noise.

- Plug-and-Play Integration: Works seamlessly with ZYGO’s measurement software (e.g., MX™) for automatic configuration and calibration, reducing setup time by 30% compared to non-integrated solutions.

4. Application Areas and Use Cases

The ZYGO 8020-0610-04 is widely used in:

- Semiconductor Manufacturing: Calibrating wafer stages in EUV lithography tools to ensure nanometer-scale alignment during chip fabrication.

- Precision Machining: Monitoring CNC machine tool motion to compensate for thermal expansion and mechanical backlash, improving part accuracy.

- Aerospace Engineering: Testing the dimensional stability of aircraft components under dynamic loads, ensuring compliance with strict tolerances.

Case Study:

A leading semiconductor foundry integrated the ZYGO 8020-0610-04 into its wafer exposure system to measure X-Y stage displacement during EUV lithography. The module’s 0.6 nm resolution and real-time feedback reduced overlay errors by 40%, improving chip yield by 12% and minimizing rework costs.

A leading semiconductor foundry integrated the ZYGO 8020-0610-04 into its wafer exposure system to measure X-Y stage displacement during EUV lithography. The module’s 0.6 nm resolution and real-time feedback reduced overlay errors by 40%, improving chip yield by 12% and minimizing rework costs.

5. Competitor Comparison

Compared to similar VMEbus interface modules, the ZYGO 8020-0610-04 offers:

- Higher Resolution: 0.6 nm vs. typical 1 nm resolution in competing products, critical for next-generation semiconductor processes.

- Faster Bandwidth: 20 kHz control bandwidth enables quicker response to motion corrections, outperforming modules with 10–15 kHz bandwidths.

- Integrated Diagnostics: Built-in health monitoring for laser signal integrity and temperature, reducing troubleshooting time by 50% compared to non-intelligent modules.

ZYGO 8020-0610-04

6. Selection Recommendations

When selecting the ZYGO 8020-0610-04, consider:

- System Compatibility: Ensure your control system uses VMEbus architecture and supports dual-axis measurement requirements.

- Resolution Needs: Choose this module if your application requires sub-nanometer precision (e.g., semiconductor lithography, metrology labs).

- Environmental Fit: Verify the operating temperature (0°C–40°C) and EMI resistance align with your setup, especially in high-vibration or noisy environments.

- Scalability: Leverage its dual-axis capability to simplify multi-axis systems, but confirm your interferometer model supports the P2 interface.

7. Precautions

- Installation:

- Use an ESD-safe workbench and grounding strap to prevent electrostatic damage during handling.

- Ensure the VMEbus backplane provides stable 5V and 12V power to avoid signal distortion.

- Operation:

- Do not exceed the rated voltage or current to prevent hardware failure.

- Calibrate the module with ZYGO’s factory-recommended procedures before initial use to ensure accuracy.

- Maintenance:

- Clean the P2 connectors quarterly with isopropyl alcohol to remove dust and oxidation.

- Update firmware via ZYGO’s MX software to access the latest performance optimizations and bug fixes.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.